Preparation method and application of stacking-coral-like biomass-charcoal-based catalyst

A biochar and catalyst technology, applied in the field of environmental engineering, can solve problems such as poor applicability, inability to use across industries, no consideration of metal dispersion, and limitation of desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

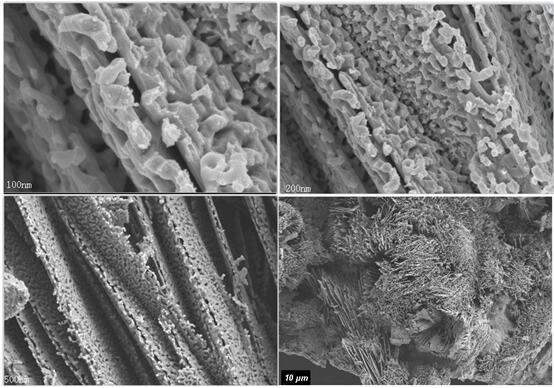

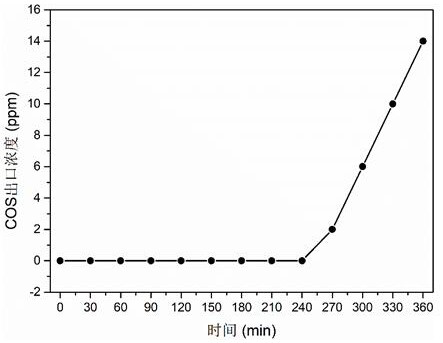

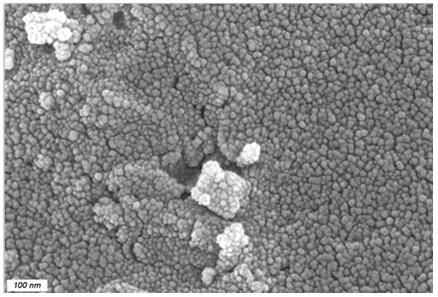

[0029] Embodiment 1: The preparation method of the coral stacked biomass carbon-based catalyst in this embodiment is as follows:

[0030] (1) Using walnut shells as biomass raw materials, carbonize at 700°C for 3 hours in a nitrogen atmosphere to obtain carbonized products;

[0031] (2) Grind the carbonized material to 40-60 mesh, wash it with water three times, and then dry it in an electric furnace at 105°C for 12 hours to obtain a biomass-based carbonized carrier;

[0032] (3) Add the biomass-based carbonized carrier to the reaction kettle containing copper nitrate solution (the mass of copper nitrate in the copper nitrate solution is 90% of the mass of the biomass-based carbonized carrier), and then add the total volume of the reaction system solution (nitric acid Copper solution + nitric acid) 2.5% nitric acid, after mixing, at 180 ° C, the hydrothermal time is 9 hours, and the biomass-based catalyst precursor is obtained;

[0033] (4) Put the biomass-based catalyst prec...

Embodiment 2

[0036] Embodiment 2: The preparation method of the coral stacked biomass carbon-based catalyst in this embodiment is as follows:

[0037] (1) Using straw as a biomass raw material, carbonize at 800°C for 2 hours in a nitrogen atmosphere to obtain carbonized products;

[0038] (2) Grind the carbonized material to 40-60 mesh, wash it with water three times, and then dry it in an electric furnace at 100°C for 12 hours to obtain a biomass-based carbonized carrier;

[0039] (3) Add the biomass-based carbonized carrier to the reaction kettle containing copper nitrate solution (the mass of copper nitrate in the copper nitrate solution is 150% of the mass of the biomass-based carbonized carrier), and then add the total volume of the reaction system solution (nitric acid Copper solution + nitric acid) 3% nitric acid, after mixing at 160°C, hydrothermal time is 10h, to prepare the biomass-based catalyst precursor;

[0040] (4) Put the biomass-based catalyst precursor in a tube furnace,...

Embodiment 3

[0042] Embodiment 3: The preparation method of the coral stacked biomass carbon-based catalyst in this embodiment is as follows:

[0043] (1) Tobacco stems were used as biomass raw materials, and charred products were obtained by carbonization at 600°C for 3 hours in a nitrogen atmosphere;

[0044] (2) Grind the carbonized material to 40-60 mesh, wash it with water three times, and then dry it in an electric furnace at 110°C for 12 hours to obtain a biomass-based carbonized carrier;

[0045] (3) Add the biomass-based carbonized carrier to the reaction kettle containing the copper nitrate solution (the mass of copper nitrate in the copper nitrate solution is 100% of the mass of the biomass-based carbonized carrier), and then add the total volume of the reaction system solution (nitric acid Copper solution + nitric acid) 2% nitric acid, mixed at 140 ° C, hydrothermal time of 12 hours, prepared biomass-based catalyst precursor;

[0046] (4) Put the biomass-based catalyst precurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com