Method for preparing high-performance carbon-graphite material through solvent pretreatment of green coke powder

A pretreatment and carbon-graphite technology, which is applied in the field of solvent pretreatment of green coke powder to prepare high-performance carbon-graphite materials, can solve the problems of long preparation process cycle, large environmental pollution, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

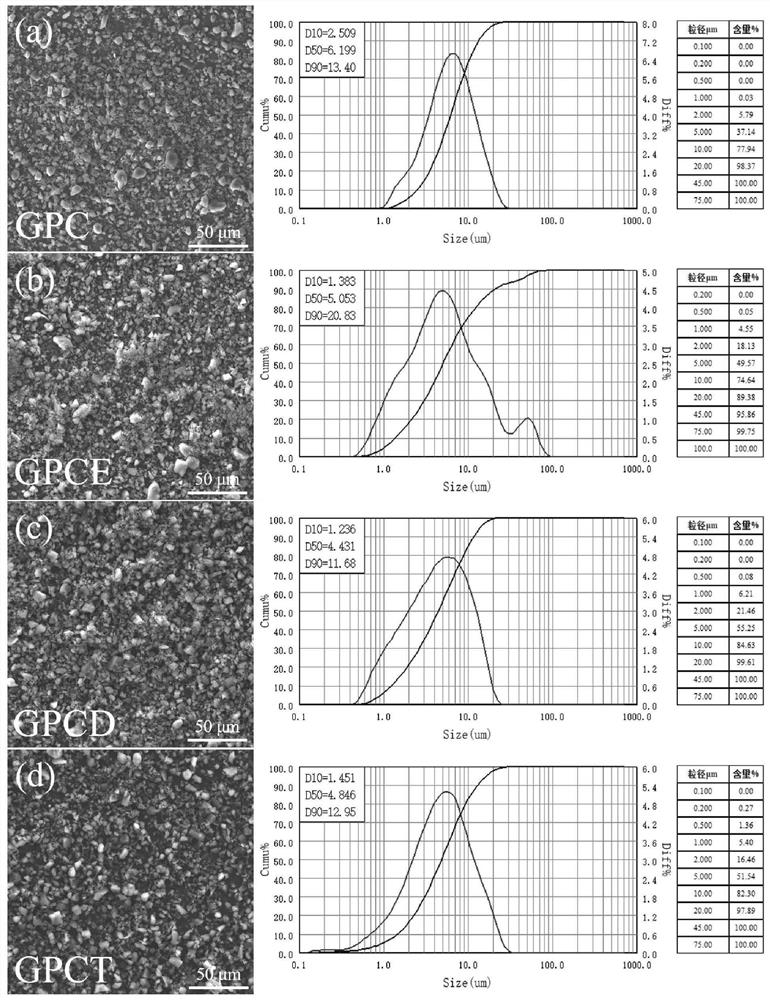

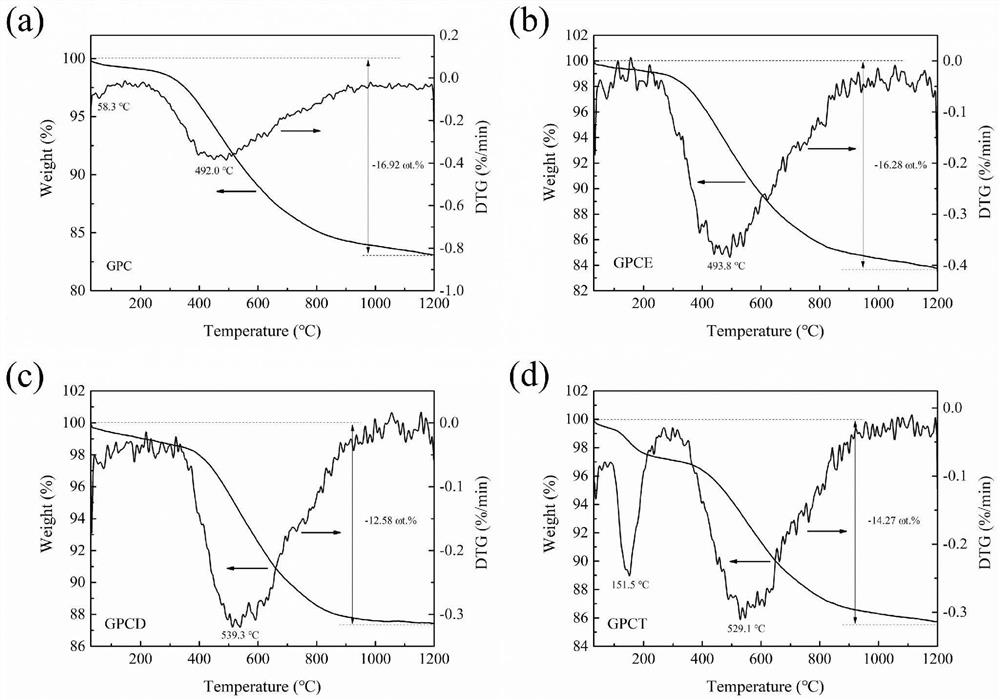

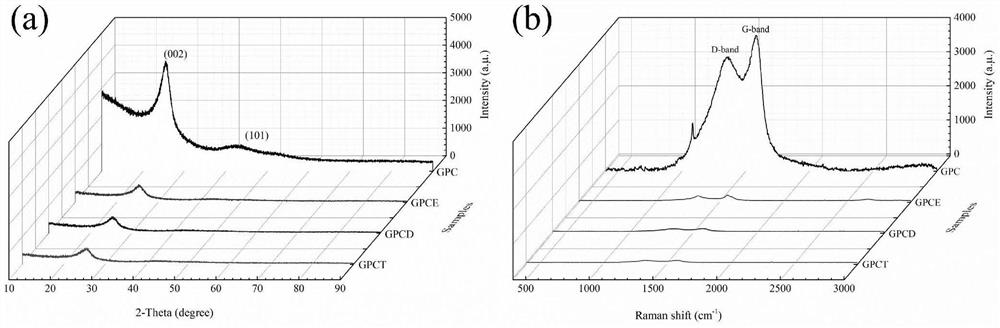

[0032] During specific implementation, the preparation method of carbon graphite material may further comprise the steps:

[0033] (1) Weigh the green coke powder, organic solvent and dispersant separately, and set aside; the particle size of the green coke powder is 2~10 μm, the mass ratio of the green coke powder and the organic solvent is 1:1~3, and the dispersant accounts for 1~3% of powder mass;

[0034] (2) Dissolve the dispersant weighed in step (1) into the organic solvent weighed in step (1), and put it into the raw coke powder weighed in step (1) in batches after dissolving evenly. Constantly forced to stir, continue to stir for a period of time after the addition is complete, then stand and age for 10-24 hours, and finally obtain pretreated green coke powder through vacuum filtration, washing and drying;

[0035] Because the surface energy of raw coke powder is relatively large, it is easy to agglomerate. Adding a dispersant here can effectively prevent the agglome...

Embodiment 1

[0052] (1) Weigh a certain amount of raw coke powder, and weigh the same amount of absolute ethanol (organic solvent) for use, and weigh cetyltrimethylammonium bromide (1% of the total mass of raw coke powder) at the same time Dispersant) spare;

[0053] (2) Dissolve the dispersant evenly in the organic solvent, put it into the green coke powder in 3 times through the combination of ultrasonic dispersion and mechanical stirring, ultrasonic time: 5 h, ultrasonic working frequency: 40 khz, mechanical stirring time: 10 h, mechanical stirring speed: 500 r / min, aging for 24 h, and set aside.

[0054] (3) Choose a medium-speed double-layer filter paper and a Buchner funnel, and wash the aging solution prepared in step (2) by vacuum filtration, wash 3 times, and the suction filtration pressure is 0.8 MPa. Dry in a vacuum drying oven for 10 h, crush and dry the sample with a high-speed universal pulverizer, and sieve through an 80-mesh sieve to obtain pretreated raw coke powder (name...

Embodiment 2

[0058] The steps are the same as in Example 1, except that the organic solvent used in Example 2 is dichloromethane, and the obtained pretreated green coke powder is named GPCD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com