Preparation method and equipment of silicon nitride powder

A technology of silicon nitride powder and equipment, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problem of reducing the production efficiency of silicon nitride powder, high raw material costs, and the inability to realize continuous preparation of silicon nitride powder, etc. problem, to achieve the effect of improving production efficiency, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] see Figure 1-8 Shown, a kind of preparation method of silicon nitride powder comprises the following steps:

[0042] The first step is to add silicon powder screened with a particle size of 0.1 μm into the feeding tank 201, close the sealing block 202, drive the protective plate 401 into the connecting groove 402 through the drive shaft of the electric push rod 403, and turn the adjusting screw 501 to make the movement The frame 30 slides downward on one side of the frame 10 until the output end of the carbon dioxide laser 40 enters the inside of the through hole 60;

[0043] In the second step, the linear motor 303 drives the feeding frame 301 to slide inside the reaction box 20 until the material guiding pipe 1 304 slides directly below the feeding tank 201, and the drive shaft of the servo electric cylinder 3 308 pushes the connecting frame 2 309 upward until the top of the feeding pipe 304 is inserted into the feeding tank 201, the servo motor 203 drives the mater...

Embodiment 2

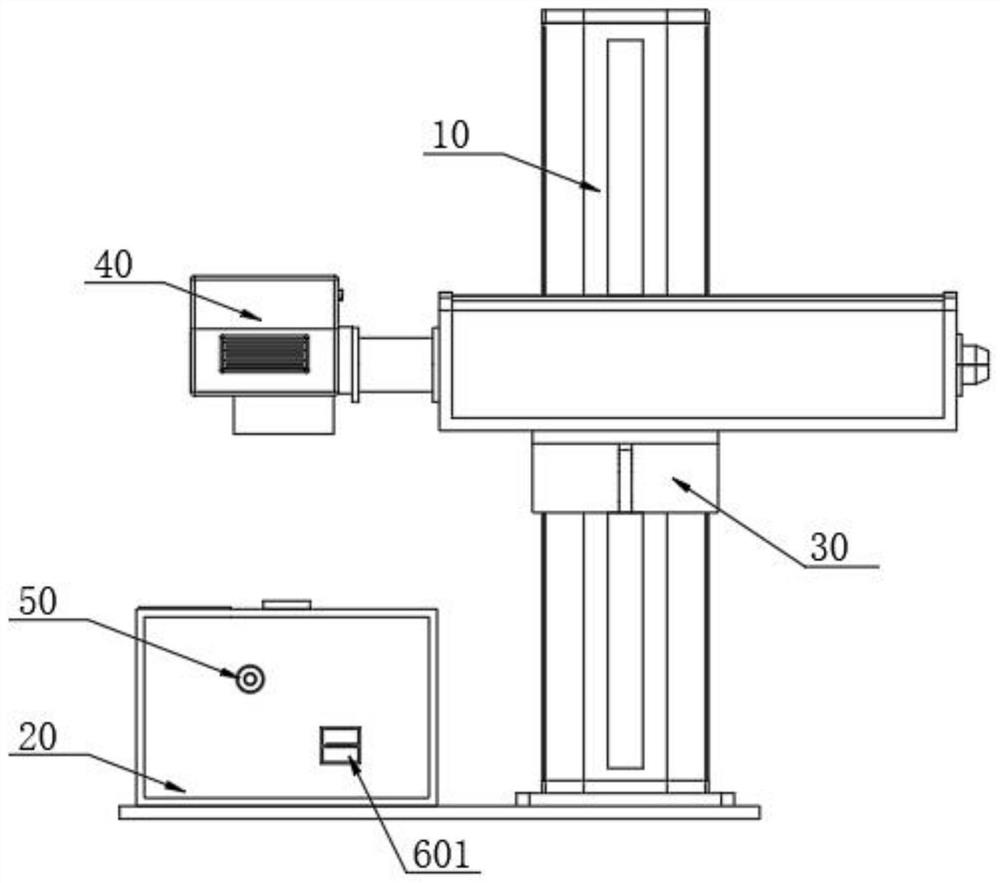

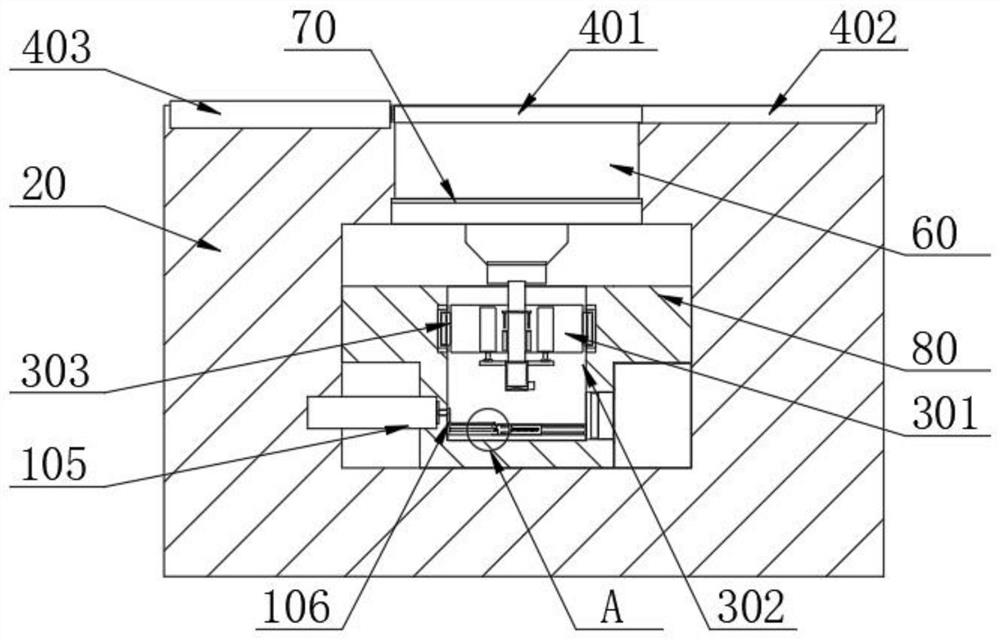

[0048] see Figure 1-3 As shown, a preparation device for silicon nitride powder includes a frame 10 and a reaction box 20 arranged on the top of the frame 10, a movable frame 30 is slidably arranged on one side of the frame 10, and a movable frame 30 is arranged on one side There is a carbon dioxide laser 40, the power of the carbon dioxide laser 40 is 5000W, and the right side of the reaction box 20 is communicated with an air duct 50, and a large amount of nitrogen gas is introduced into the interior of the reaction box 20 through the air duct 50, and the silicon material is in the nitrogen atmosphere of the reaction box 20. A photochemical reaction is generated in the middle, and finally silicon nitride powder is produced. A through hole 60 is provided above the inside of the reaction box 20, and a transparent plate 70 is arranged below the inside of the through hole 60. A fixing frame 80 is arranged inside the reaction box 20, and fixed The inside of the frame 80 is provi...

Embodiment 3

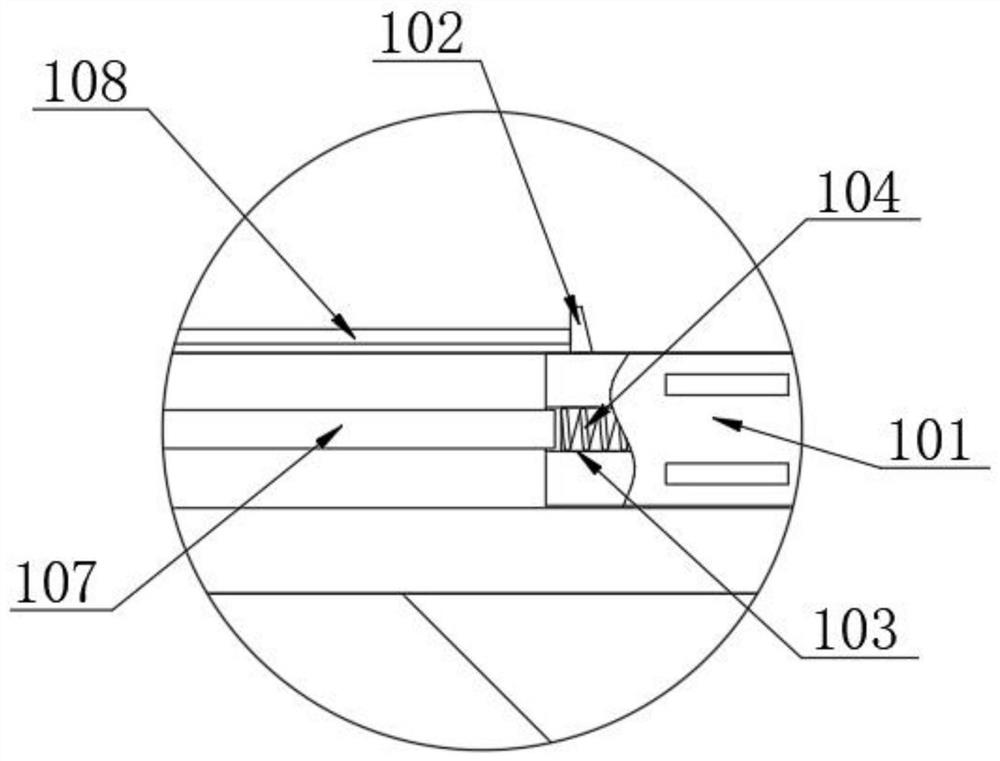

[0050] see Figure 4-5 As shown, in the present invention, a feeding mechanism is provided on the left side inside the reaction box 20, and the feeding mechanism includes a feeding tank 201, and a sealing block 202 is arranged above the inside of the feeding tank 201, and a servo motor 203 is arranged inside the sealing block 202, and One end of the output shaft of the servo motor 203 is fixedly connected with a rotating rod 204 through a coupling, and the bottom of the feeding tank 201 is provided with a material distribution plate 205, and the bottom of the rotation rod 204 is rotationally connected with the top of the material distribution plate 205. The inside of the plate 205 is provided with two arc grooves 206, and the inside of the two arc grooves 206 is provided with a material stopper 207, and the material stopper 207 is used to rotate inside the arc groove 206 to realize the circular arc groove 206. For the on-off of the top and bottom of the feeding tank 201 , one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com