Fermentation equipment and fermentation method

A technology of fermentation equipment and fermentation tanks, which is applied in fermentation-related fields, can solve problems such as unfavorable automatic production, uneven heating of fermentation materials, and long fermentation time, and achieve the effects of unmanned production, improved fermentation quality, and reduced fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

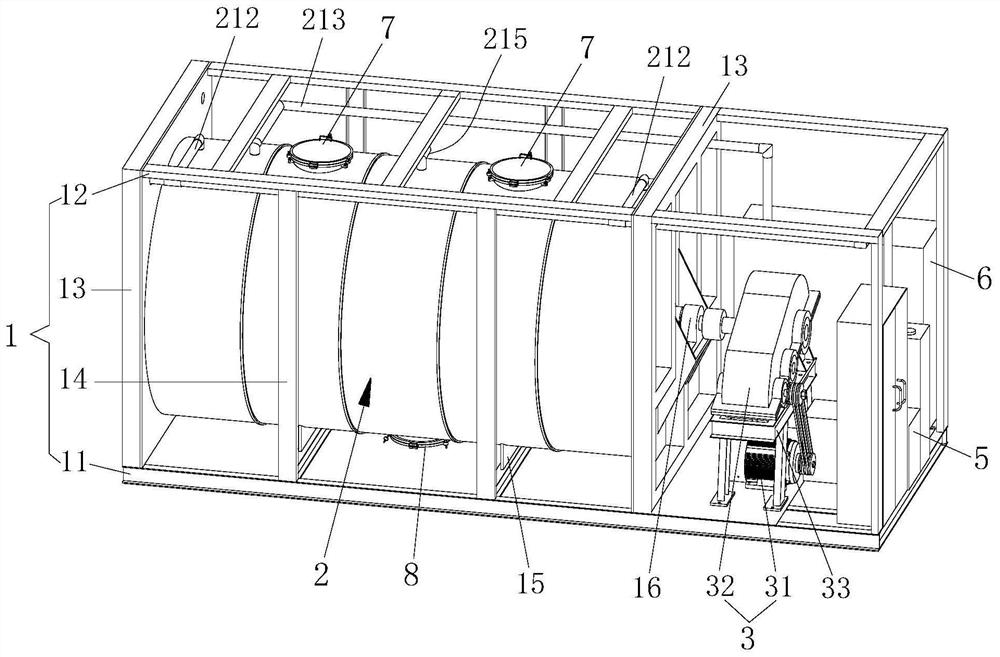

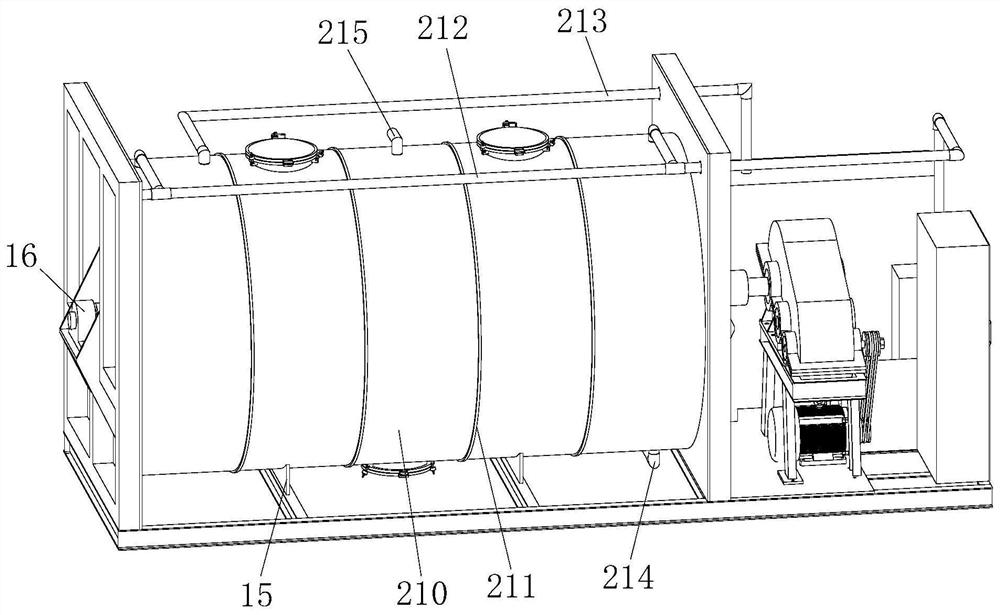

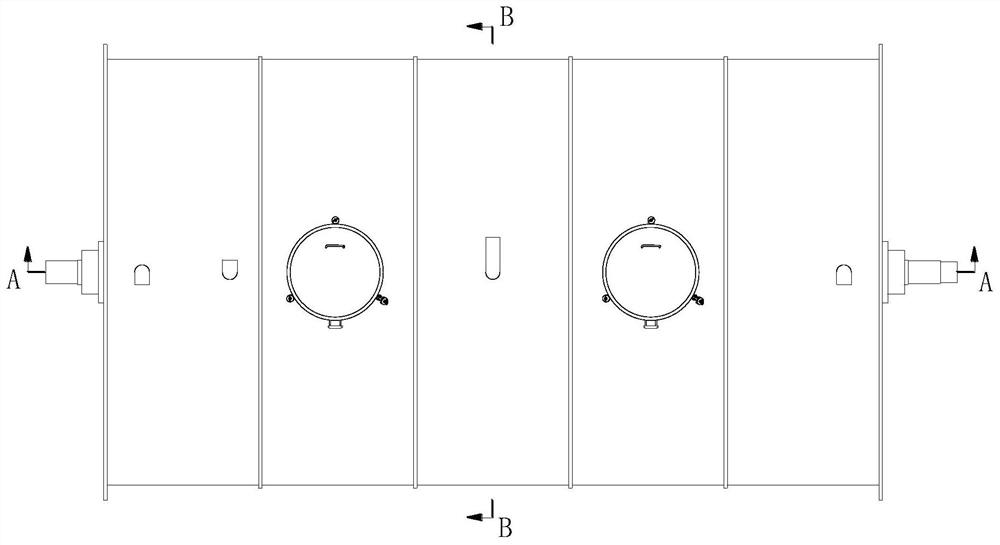

[0037] like Figure 1 to Figure 7 As shown, a fermentation equipment provided by the present invention includes: a support frame 1, a fermentation tank 2, a power drive device 3, a stirring shaft 4, a vacuum pump 5, a liquid heating device 6, and a control device.

[0038]The support frame 1 is mainly composed of a bottom frame 11, a top frame 12, two side frames 13 connected with the bottom frame 11 and the top frame 12, and a plurality of support rods 14. The bottom frame 11 is provided with a support plate 15, and the support plate 15 The top is arc-shaped. In other embodiments, the support frame 1 can be composed of two side frames 13, or can be composed of a bottom frame 11 and two side frames 13 fixed on the bottom frame 11. The specific structure of the support frame 1 can be determined according to actual needs. Any customization.

[0039] Fermentation tank 2 is located in support frame 1, and fermentation tank 2 comprises outer tank body 21, inner tank body 22, and ...

Embodiment 2

[0053] A kind of fermentation method based on the fermentation equipment of embodiment one, comprises the following steps:

[0054] Use a dry-wet separator / filter press to reduce the water content of the fermentation raw materials to less than 70%. After the fermentation auxiliary materials are crushed with a pulverizer, add the fermentation raw materials and fermentation auxiliary materials into the inner tank at a weight ratio of 2.5-3.5:1. Add fermentation strains at the same time, wherein, the fermentation raw material is at least one of chicken manure, duck manure, pig manure, cow manure, and sheep manure, and the fermentation auxiliary materials are wood flour, sawdust, rice bran, wheat flour, peanut shells, and bellflower At least one in the broken powder; fermented strains include Bacillus subtilis, Bacillus licheniformis, and Bacillus megaterium, and its weight ratio is respectively 15 parts, 25 parts, 30 parts, and the weight ratio of fermented strains and fermentatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap