Bio-organic fertilizer with soil structure improving function and preparation method thereof

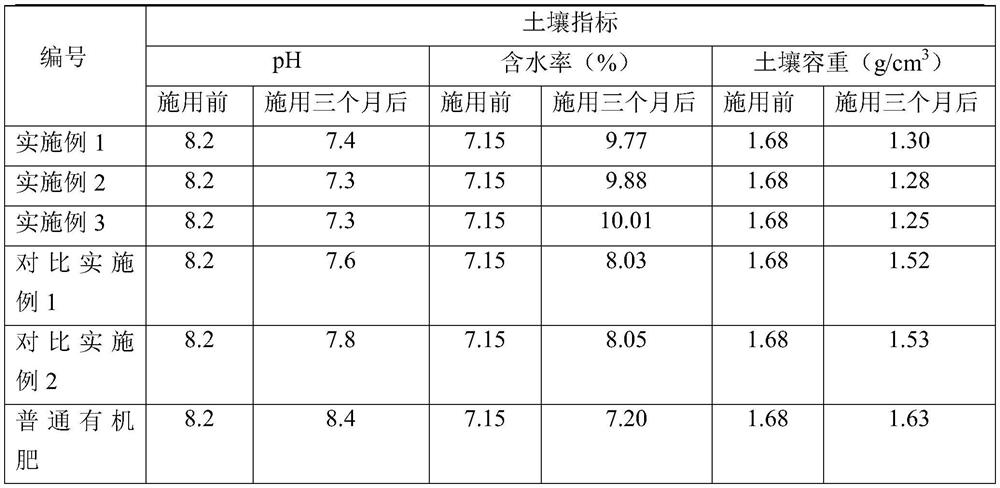

A bio-organic fertilizer and soil-improving technology, applied in the field of bio-organic fertilizer and its preparation, can solve the problems of affecting soil aggregate structure, insufficient farmyard manure, affecting microbial activity, etc., so as to reduce soil bulk density, achieve better effect and realize recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing bio-organic fertilizer with the function of improving soil structure, comprising the steps of:

[0030] (1) Sludge fermentation: Add calcium peroxide powder, porous hydroxyapatite powder and anaerobic fermentation agent to the sludge, mix well and carry out anaerobic fermentation in an anaerobic fermentation tank, and control the temperature during the fermentation process Fermentation at 55-65° C. for 48 hours to obtain a sludge fermented product; wherein, the weight ratio of calcium peroxide powder, porous hydroxyapatite powder and sludge is 0.2:0.01:1.

[0031] It should be noted that the porous hydroxyapatite powder in this example is the prior art, specifically, in this example, it is prepared by using the "Preparation Method of Porous Hydroxyapatite" in CN108079382B.

[0032] In addition, in order to avoid the introduction of substances that cause harm to compacted soil, the organic matter contained in the sludge in this example is below 10%...

Embodiment 2

[0036] A method for preparing bio-organic fertilizer with the function of improving soil structure, comprising the steps of:

[0037] (2) Sludge fermentation: Add calcium peroxide powder, porous hydroxyapatite powder and anaerobic fermentation agent to the sludge, mix well and carry out anaerobic fermentation in an anaerobic fermentation tank, and control the temperature during the fermentation process Ferment at 50-60° C. for 60 hours to obtain a sludge fermented product; wherein, the weight ratio of calcium peroxide powder, porous hydroxyapatite powder and sludge is 0.1:0.02:1.

[0038] (2) After adding pulverized corn stalks, pig manure and fermented bacterial agent to the sludge fermented product obtained in step (1), mix evenly, and carry out heap fermentation for 90 days, during which the heap is turned over more than 3 times irregularly, Obtain secondary fermented product, standby;

[0039] (3) When it needs to be applied to compacted soil, calcium peroxide powder, por...

Embodiment 3

[0041] A method for preparing bio-organic fertilizer with the function of improving soil structure, comprising the steps of:

[0042] (3) Sludge fermentation: Add calcium peroxide powder, porous hydroxyapatite powder and anaerobic fermentation bacteria agent to the sludge, mix well and carry out anaerobic fermentation in an anaerobic fermentation tank, and control the temperature during the fermentation process Ferment at 52-60° C. for 72 hours to obtain a sludge fermented product; wherein, the weight ratio of calcium peroxide powder, porous hydroxyapatite powder and sludge is 0.4:0.02:1.

[0043] (2) After adding pulverized corn and tobacco stalks, cow dung and fermented bacteria to the sludge fermented product obtained in step (1), mix them evenly, carry out heap fermentation for 120 days, and turn over the heap every 20 days during the period , to obtain a secondary fermented product for subsequent use;

[0044] (3) When it needs to be applied to compacted soil, calcium pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com