Ultraviolet irradiation cross-linked polyolefin material and preparation method thereof

A technology of crosslinking polyolefin and ultraviolet light, which is applied in the field of polyolefin, can solve the problems of poor crosslinking uniformity, poor high temperature resistance, free radical collision, etc., and achieve the effect of easy control, simple preparation method and avoiding degradation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

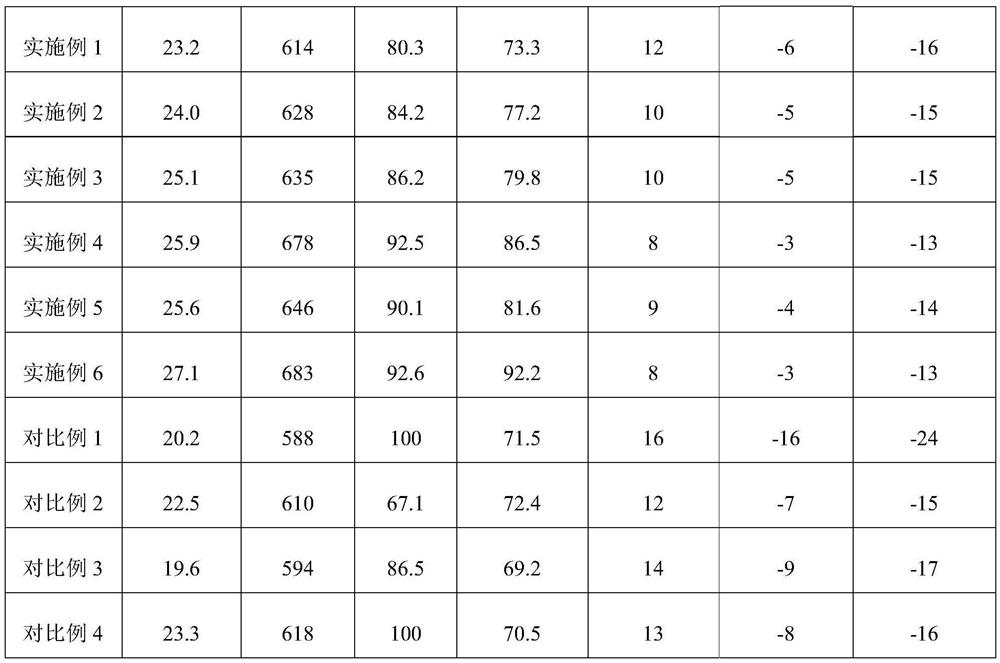

Embodiment 1

[0030] A UV-irradiated crosslinked polyolefin material, comprising the following components by weight:

[0031] 40 parts of polyolefin; 1 part of first photoinitiator; 5 parts of bonding agent; 20 parts of polymer precursor; 0.1 part of second photoinitiator; 0.1 part of crosslinking agent; 1 part of silane coupling agent; 0.01 part of light stabilizer . Wherein, the polyolefin is composed of polyethylene and polypropylene with a mass ratio of 1:0.8; the first photoinitiator is 2,2-dimethoxy-2-phenylacetophenone; the second The photoinitiator is methyl benzoate; the bonding agent is three (2-methylaziridine) phosphine oxide; the cross-linking agent is polyethylene glycol dimethacrylate; the polymer precursor is Methyl methacrylate; the silane coupling agent is vinyltrimethoxysilane; the light stabilizer consists of a hindered amine light stabilizer and a triazine ultraviolet absorber with a mass ratio of 1:0.3:0.3:0.2 , benzotriazole UV absorber, and benzophenone UV absorber...

Embodiment 2

[0038] A UV-irradiated crosslinked polyolefin material, comprising the following components by weight:

[0039] 50 parts of polyolefin; 3 parts of first photoinitiator; 10 parts of bonding agent; 25 parts of polymer precursor; 0.5 part of second photoinitiator; 0.5 part of crosslinking agent; 2 parts of silane coupling agent; share. Wherein, the polyolefin is composed of polyethylene and polypropylene with a mass ratio of 1:0.8; the first photoinitiator is 2,2-dimethoxy-2-phenylacetophenone; the second The photoinitiator is methyl benzoate; the bonding agent is three (2-methylaziridine) phosphine oxide; the cross-linking agent is polyethylene glycol dimethacrylate; the polymer precursor is Methyl methacrylate; the silane coupling agent is vinyltrimethoxysilane; the light stabilizer consists of a hindered amine light stabilizer and a triazine ultraviolet absorber with a mass ratio of 1:0.3:0.3:0.2 , benzotriazole UV absorber, and benzophenone UV absorber.

[0040] A preparat...

Embodiment 3

[0046] A UV-irradiated crosslinked polyolefin material, comprising the following components by weight:

[0047] 60 parts of polyolefin; 5 parts of first photoinitiator; 15 parts of bonding agent; 30 parts of polymer precursor; 1 part of second photoinitiator; 1 part of crosslinking agent; 3 parts of silane coupling agent; 0.1 parts of light stabilizer share. Wherein, the polyolefin is composed of polyethylene and polypropylene with a mass ratio of 1:0.8; the first photoinitiator is 2,2-dimethoxy-2-phenylacetophenone; the second The photoinitiator is methyl benzoate; the bonding agent is three (2-methylaziridine) phosphine oxide; the cross-linking agent is polyethylene glycol dimethacrylate; the polymer precursor is Methyl methacrylate; the silane coupling agent is vinyltrimethoxysilane; the light stabilizer consists of a hindered amine light stabilizer and a triazine ultraviolet absorber with a mass ratio of 1:0.3:0.3:0.2 , benzotriazole UV absorber, and benzophenone UV abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com