Method for producing biogas through combined anaerobic fermentation of pig farm manure water treated by biochar-loaded nanoscale zero-valent iron and corn straws

A technology of nano-zero-valent iron and corn stalks, which is applied in the field of resource utilization of agricultural waste, can solve the problems of low gas production rate and long fermentation cycle, and achieve the goal of improving gas production efficiency, increasing methane content, and improving gas production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

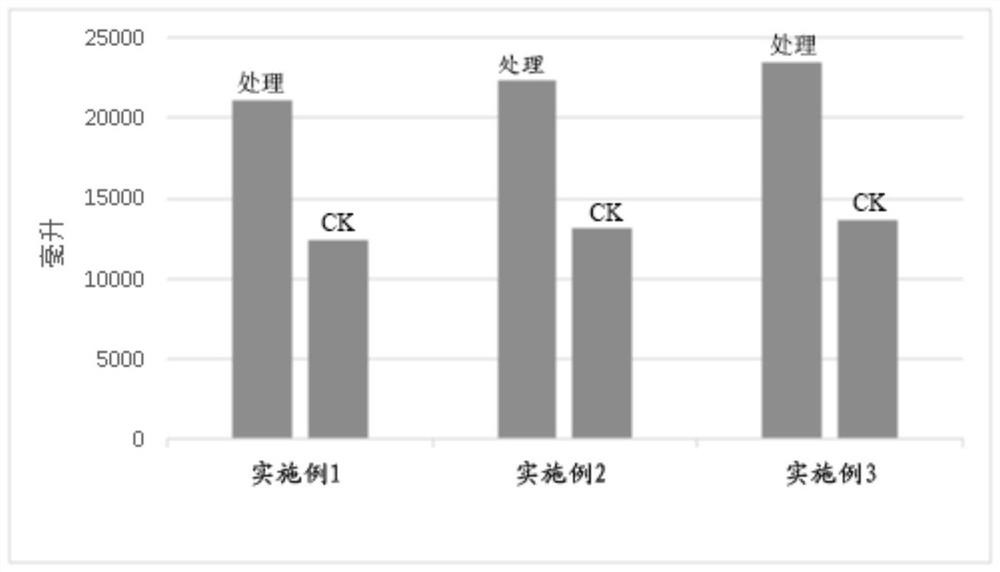

Embodiment 1

[0057] Biochar is obtained from corn straw by oxygen-limited pyrolysis at 400°C (Tao Mengjia. Preparation and modification of straw biochar and research on the adsorption efficiency of nitrogen and phosphorus in water [D]. Harbin Institute of Technology, 2018. Dissertation) , Nano-sized zero-valent iron loaded on biochar is prepared by pyrolysis-liquid phase reduction method (Zhu Qingtao, Wu Xiaoyi, Guo Qihui, et al. Research progress on the preparation of nano-sized zero-valent iron loaded on biochar and its removal of pollutants in water[J].Energy Chemical Industry, 2018, 39(04):73-77).

[0058] In this example, the method of anaerobic fermentation of pig farm manure treated with nano-zero-valent iron loaded with biochar and corn stalks to produce biogas is realized in the following steps:

[0059] Step 1. Filter the pig farm manure to remove impurities such as sand and plastic, and put it into a plastic bucket for later use.

[0060] Step 2, crushing the corn stalks to 1-3...

Embodiment 2

[0068] In this example, the method of anaerobic fermentation of pig farm manure treated with nano-zero-valent iron loaded with biochar and corn stalks to produce biogas is realized in the following steps:

[0069] Step 1. Filter the pig farm manure to remove impurities such as sand and plastic, and put it into a plastic bucket for later use;

[0070] Step 2, crushing the corn stalks to 1-3 cm, and drying the crushed corn stalks to a constant weight by using a blast drying oven;

[0071] Step 3. Fill the pig farm manure water into 500mL serum bottles, and fill each serum bottle with 372 mL;

[0072] Step 4: Put 30mg of biochar-loaded nano-zero-valent iron into a 500mL serum bottle, and quickly place the serum bottle in an air bath constant temperature oscillator at 35.0±0.5°C at a frequency of 80rpm for 24h;

[0073]Step 5. Weigh 28 g of dried corn stalks, put them into the serum bottle of step 4, store them at medium temperature for 3 days, add 40 mL of active strains of 40 m...

Embodiment 3

[0078] In this example, the method of anaerobic fermentation of pig farm manure treated with nano-zero-valent iron loaded with biochar and corn stalks to produce biogas is realized in the following steps:

[0079] Step 1. Filter the pig manure water to remove impurities such as sand and plastic, and put it into a plastic bucket for later use;

[0080] Step 2, crushing the corn stalks to 1-3 cm, and drying the crushed corn stalks to a constant weight by using a blast drying oven;

[0081] Step 3: Fill pig manure water into 500mL serum bottles, and fill each serum bottle with 368 mL.

[0082] Step 4: Put 50mg of biochar-loaded nano-zero-valent iron into a 500mL serum bottle, and quickly place the serum bottle in an air bath constant temperature oscillator at 35.0±0.5°C at a frequency of 100rpm for 36h.

[0083] Step 5. Weigh 32g of dried corn stalks, put them into the serum bottle of step 4, store at medium temperature for 3 days, add 40mL of active bacteria, add water to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com