Negative electrode surface protection method suitable for solid-state lithium battery and secondary lithium battery

A secondary lithium battery, solid-state lithium technology, used in battery electrodes, secondary battery repair/maintenance, negative electrodes, etc., can solve problems such as capacity decay, dead lithium, side reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] All the preparation processes in this example are carried out in a dry environment with a dew point ≤ 45°C.

[0042] Preparation of polymer film: Add 10.5g of PEO to 25g of acetonitrile to make a film solution, coat it on the surface of polyimide substrate, evaporate the solvent at 80°C, and dry at 60°C for 12 hours under vacuum to obtain a film with a thickness of 12μm. PEO polymer film.

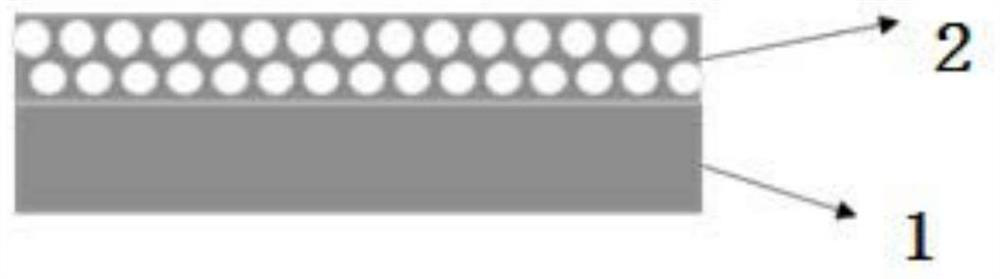

[0043] Transferring the polymer film: the polymer film is then transferred from the substrate to the surface of the metal lithium negative electrode 1 by roll-to-roll rolling.

[0044] Preparation of infiltration solution: add 13gLiTFSI and 7gDOL to 4gTHF and 4gDME in turn to prepare the infiltration solution.

[0045] Preparation of protective layer 2: using a micro-gravure coating process, coating the immersion solution on the surface of the metal lithium negative electrode 1 covered with a PEO polymer film, adjusting the tape speed, oven wind speed and temperature, and then placi...

Embodiment 2

[0047] All the preparation processes in this example are carried out in a dry environment with a dew point ≤ 45°C.

[0048] Preparation of polymer film: 4.66g PAN and 6g LLZTO were sequentially added to 20g DMAC to form a film solution, coated on the surface of polyimide substrate, the solvent was evaporated at 80°C, and then vacuum-dried at 60°C for 12h to obtain PAN and LLZTO composite polymer film (thickness 8 μm).

[0049] Transferring the polymer film: Then, the composite film is transferred from the substrate to the surface of the metal lithium negative electrode 1 by roll-to-roll rolling.

[0050] Prepare the infiltration solution: mix 10g LiTFSI, 2.8g LiNO 3 , 7g DOL were sequentially added to 3gDEC and 4gDME to make the infiltration solution.

[0051] Preparation of protective layer 2: Using an extrusion process, apply the immersion solution on the metal lithium negative electrode 1 covered with a polymer film on the surface. Since the coating equipment used has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com