Natural hyperbolic metamaterial Cu2Te micron disc random laser and preparation method and application thereof

A random laser, a natural technology, applied in the field of random laser, can solve the problems of high threshold and low power of random laser, and achieve the effect of shortening the life of self-emission transition, high gain and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Natural hyperbolic metamaterial Cu of the present invention 2 The preparation method of Te microdisk random laser, specifically comprises the following steps:

[0050] (1) Deposit and grow Cu on the growth substrate 2 Te micro disc;

[0051] Wherein, the growth substrate is a copper foam substrate or a common copper sheet. Moreover, deposition and growth of Cu on the growth substrate 2 Before the Te micron disc, the growth substrate must be pre-treated; the pre-treatment includes acetone ultrasonic cleaning, anhydrous ethanol ultrasonic cleaning and plasma surface cleaning at least one treatment method. Preferably, the plasma surface cleaning is by nitrogen gun cleaning.

[0052] In a preferred embodiment, the Cu is deposited and grown on the growth substrate by chemical vapor deposition. 2 Te microdisk.

[0053] (2) the Cu 2 Te microdisks were transferred to the substrate, the Cu 2 Deposit GaTe film on Te micro disk;

[0054] Wherein, in order to prevent conta...

Embodiment 1

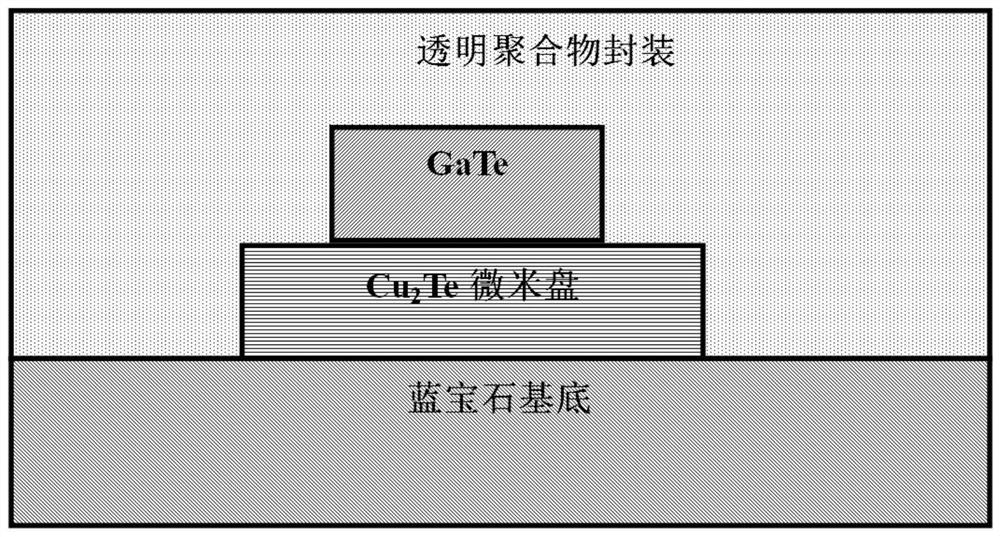

[0060] The natural hyperbolic metamaterial Cu of the present embodiment 2 Te microdisk random laser is a two-dimensional material-assisted growth random laser device, which includes sapphire substrate, Cu 2 Te microdisk and GaTe layer film, on sapphire substrate, Cu 2 The overall structure of the Te micro disk and the GaTe film is covered with a flexible packaging protection layer.

[0061] Among them, the polydimethylsiloxane (PDMS) of the flexible packaging protective layer.

[0062] The natural hyperbolic metamaterial Cu 2 Fabrication of Te microdisk random lasers using chemical vapor deposition and radio frequency magnetron sputtering to prepare Cu 2 Te microdisk with GaTe thin film gain layer.

[0063] The specific preparation process is as follows:

[0064] (1) The foamed copper substrate after ultrasonic cleaning with absolute ethanol is fixed upside down on the quartz ark workpiece in the chemical vapor deposition tube furnace chamber, the quartz ark is placed wit...

Embodiment 2

[0078] The natural hyperbolic metamaterial Cu of the present embodiment 2 Te microdisk random laser is a two-dimensional material-assisted growth random laser device, which includes sapphire substrate, Cu 2 Te microdisk and GaTe layer film, on sapphire substrate, Cu 2 The overall structure of the Te micro disk and the GaTe film is covered with a flexible packaging protection layer.

[0079] Wherein, the material of the flexible packaging protective layer is epoxy resin.

[0080] The natural hyperbolic metamaterial Cu 2 Fabrication of Te microdisk random lasers using chemical vapor deposition and radio frequency magnetron sputtering to prepare Cu 2 Te microdisk with GaTe thin film gain layer.

[0081] The specific preparation process is as follows:

[0082] (1) Fix the foamed copper substrate after the ultrasonic treatment of absolute ethanol on the quartz ark workpiece in the chemical vapor deposition tube furnace chamber. The quartz ark is placed with 6 mg Te of the evap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com