Ternary composite oxide matrix material, ternary positive electrode material, preparation method and lithium ion battery prepared from ternary composite oxide matrix material and ternary positive electrode material

A composite oxide and lithium-ion battery technology, which is applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve storage and safety performance problems, difficult to stabilize nickel, manganese dissolution and other problems, and achieve a solution Unstable structure, improved life and performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

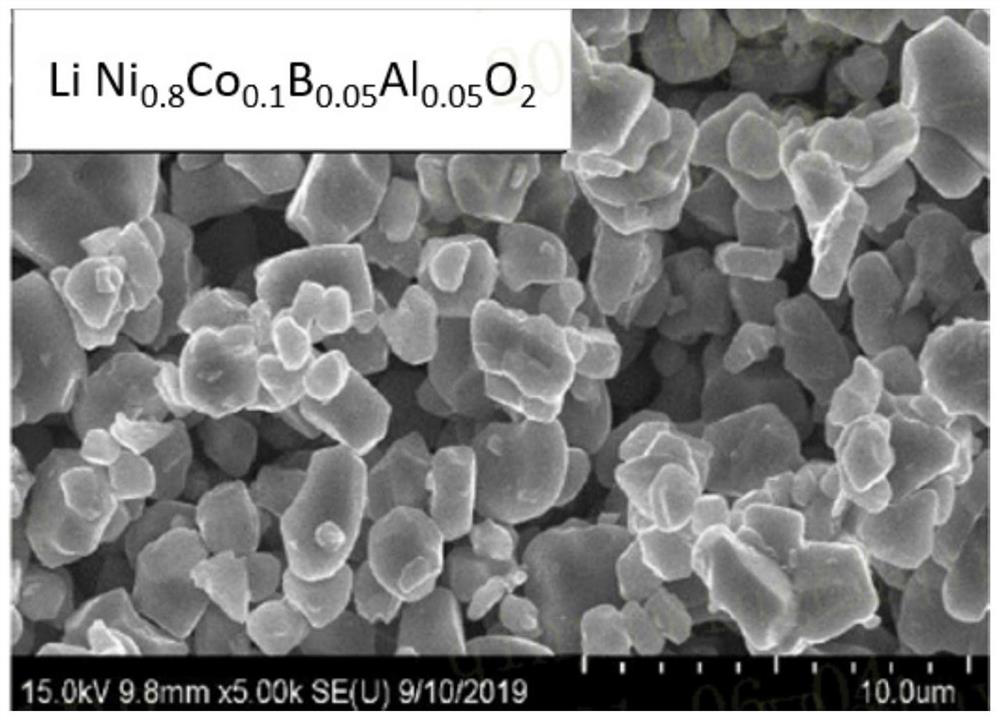

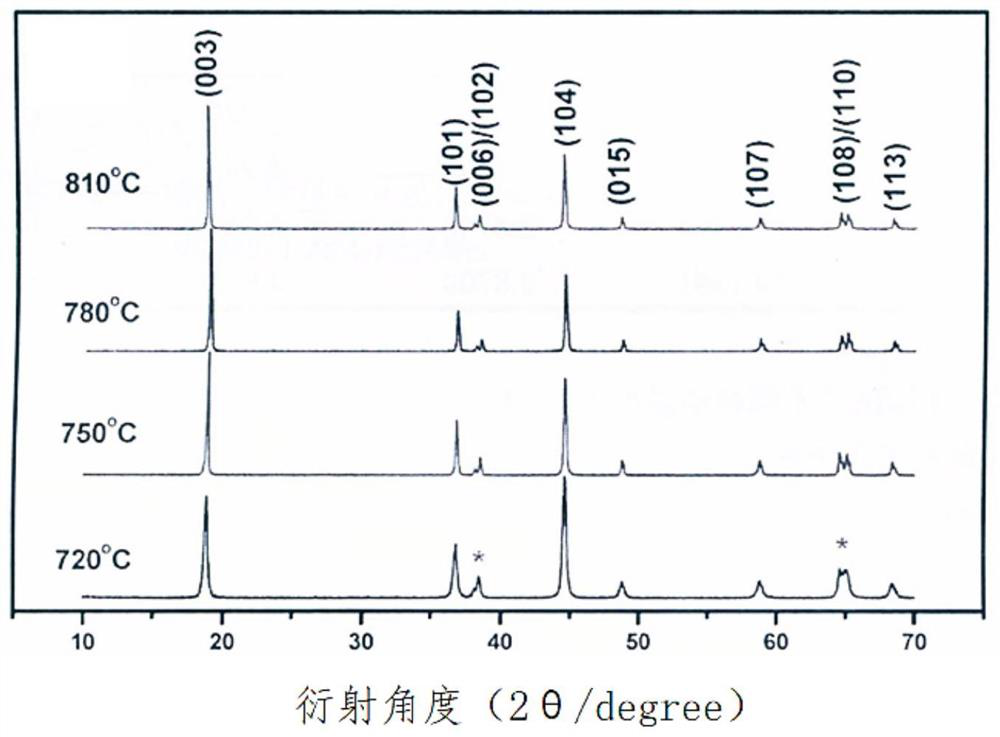

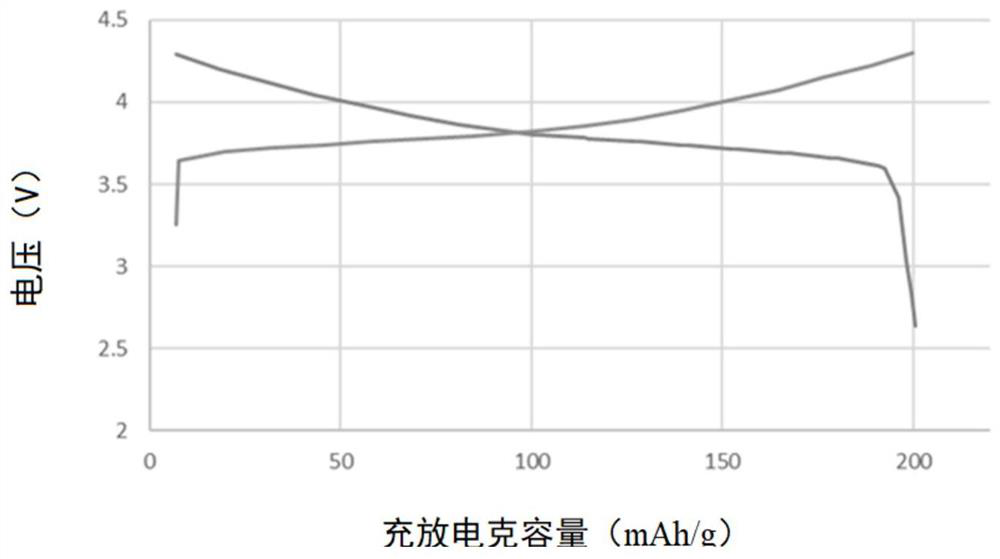

[0057] A preparation method of a ternary cathode material, comprising the steps of:

[0058] (1) Mix nickel sulfate solution, cobalt sulfate solution, boric acid solution, and aluminum sulfate solution in a Ni:Co:B:Al molar ratio of 80:10:5:5, and then add NaOH to the solution for neutralization. In the process of mixing, it is necessary to control the pH value to 11. By controlling the rotating speed (100 rpm), first wash with NaOH solution and then wash with water to remove impurities such as sulfur and sodium, and obtain the ternary hydroxide Ni 0.8 co 0.1 B 0.05 Al 0.05 (OH) 2 The precipitate was then filtered, washed, and dried at 100°C for 8 hours;

[0059] (2) In the atmosphere furnace, oxygen is introduced, and the product obtained in step (1) is heat-treated at 500 ° C for 11 hours and then naturally cooled to obtain the oxide Ni 0.8 co 0.1 B 0.05 Al 0.05 o 2 ;

[0060] (3) Mix the oxide and lithium hydroxide obtained in step (2) by the metal cation in the o...

Embodiment 2

[0067] A preparation method of a ternary cathode material, comprising the steps of:

[0068] (1) Mix nickel sulfate solution, cobalt sulfate solution, boric acid solution, and aluminum sulfate solution in a molar ratio of Ni:Co:B:Al of 80:10:5:5, then add KOH solution to the solution for neutralization, During the neutralization process, it is necessary to control the pH value to 12. By controlling the rotational speed (30 rpm), first wash with KOH solution and then wash with water to remove impurities such as sulfur and sodium, and obtain the ternary hydroxide Ni 0.8 co 0.1 B 0.05 Al 0.05 (OH) 2 The precipitate was then filtered, washed, and dried at 150°C for 4 hours;

[0069] (2) In the atmosphere furnace, air is introduced, and the product obtained in step (1) is heat-treated at 500 ° C for 11 hours and then naturally cooled to obtain the oxide Ni 0.8 co 0.1 B 0.05 Al 0.05 o 2 ;

[0070] (3) Mix the oxide and lithium hydroxide obtained in step (2) by the metal ca...

Embodiment 3

[0074] A preparation method of a ternary cathode material, comprising the steps of:

[0075] (1) Nickel sulfate solution, cobalt sulfate solution, boric acid solution, aluminum sulfate solution, by Ni:Co:B:Al molar ratio is 80:10:5:5 and mix uniformly, then add ammonia solution to neutralize in the solution, During the neutralization process, it is necessary to control the pH value to 11. By controlling the rotational speed (50 rpm), first wash with NaOH and KOH solution and then wash with water to remove impurities such as sulfur and sodium, and obtain the ternary hydroxide Ni 0.8 co 0.1 B 0.05 Al 0.05 (OH) 2 The precipitate was then filtered, washed, and dried at 120°C for 6 hours;

[0076] (2) In the atmosphere furnace, oxygen is introduced, and the product obtained in step (1) is heat-treated at 500 ° C for 11 hours and then naturally cooled to obtain the oxide Ni 0.8 co 0.1 B 0.05 Al 0.05 o 2;

[0077] (3) Mix the oxide and lithium hydroxide obtained in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com