Preparation method and application of a cobalt-iron bimetallic organic framework derived carbon material

An organic framework and bimetal technology, which is applied in the field of preparation of bimetallic organic framework derived carbon materials, can solve the problems of poor electrical conductivity of metal organic framework derived carbon materials, difficulty in controlling the morphology of bimetallic MOF, and poor material performance of the preparation method. , to achieve excellent methanol oxidation activity, good cycle stability, and reduce uncontrollable growth and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Add 1.455g of cobalt nitrate hexahydrate and 0.209g of ferrous sulfate heptahydrate to a container filled with N 2 Bubble 20

[0041] After 1 min, in a three-necked flask of 100mL methanol solution, the solution was sealed, and magnetically stirred to obtain solution A after the solid was completely dissolved;

[0042] (2) Take 12.016g of dimethylimidazole solid and add it to a beaker containing 100ml of methanol, and stir it magnetically. After the solution is completely dissolved, pour nitrogen into the solution A in (1) after bubbling for 20 minutes, and continue Stir for 1h to obtain solution B;

[0043] (3) The solution B was left standing at room temperature for 18 hours, filtered, washed with distilled water and methanol, and dried in a vacuum oven at 70°C for 24 hours to obtain solid C;

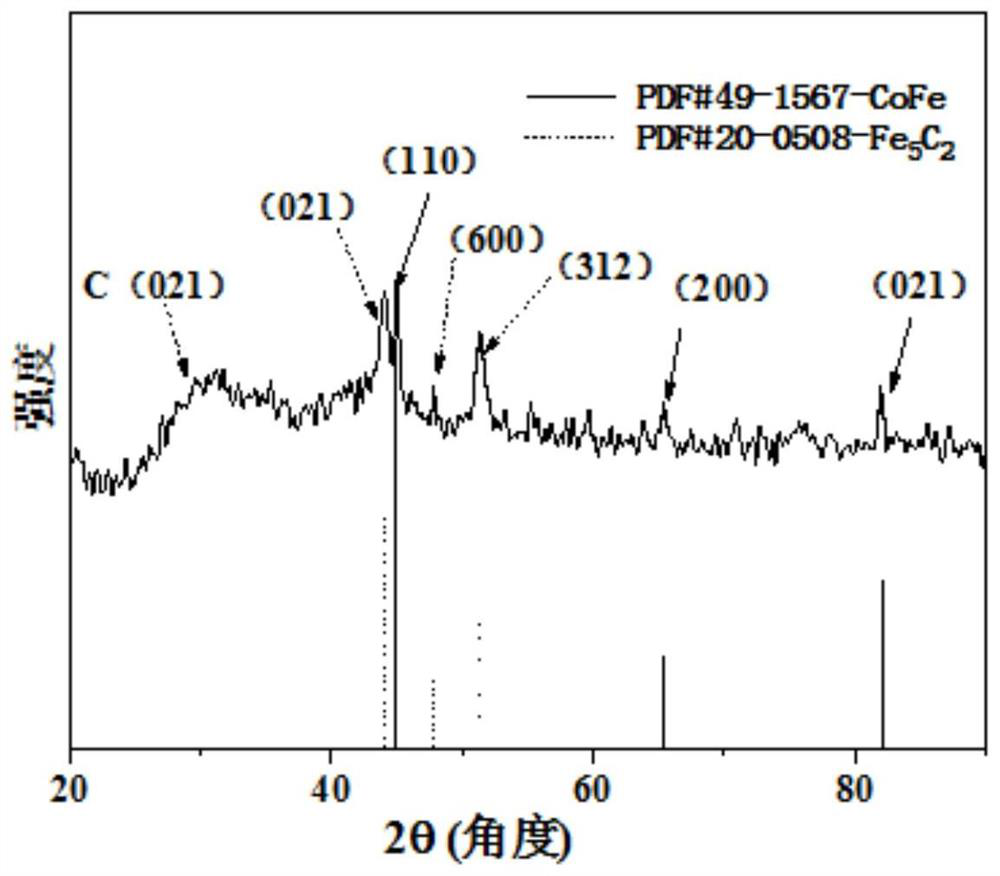

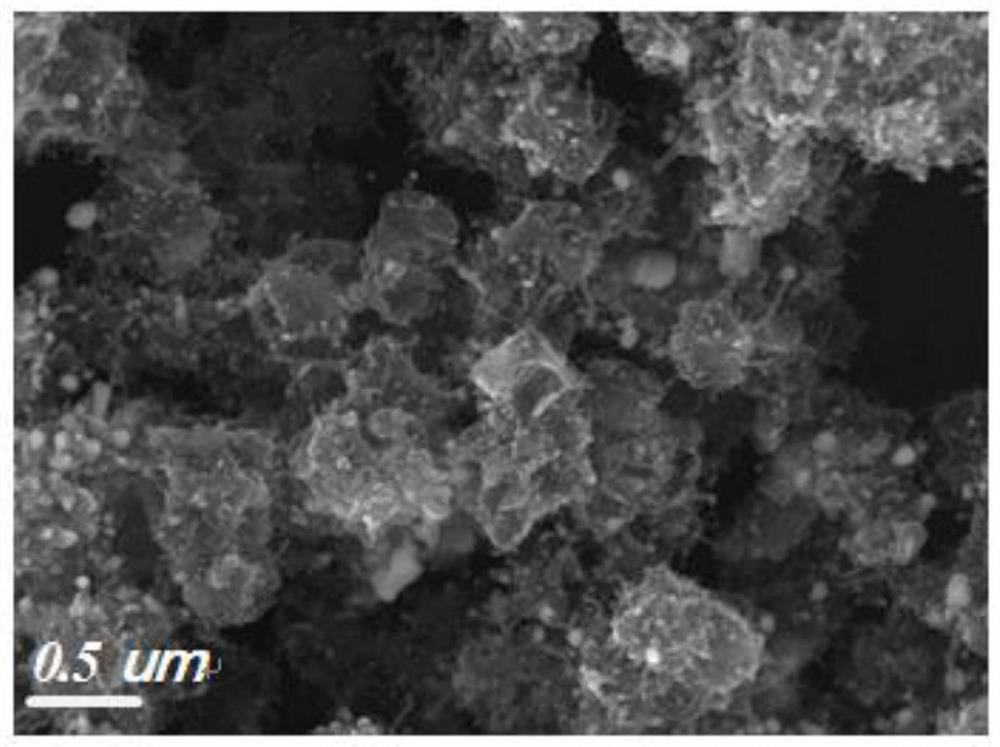

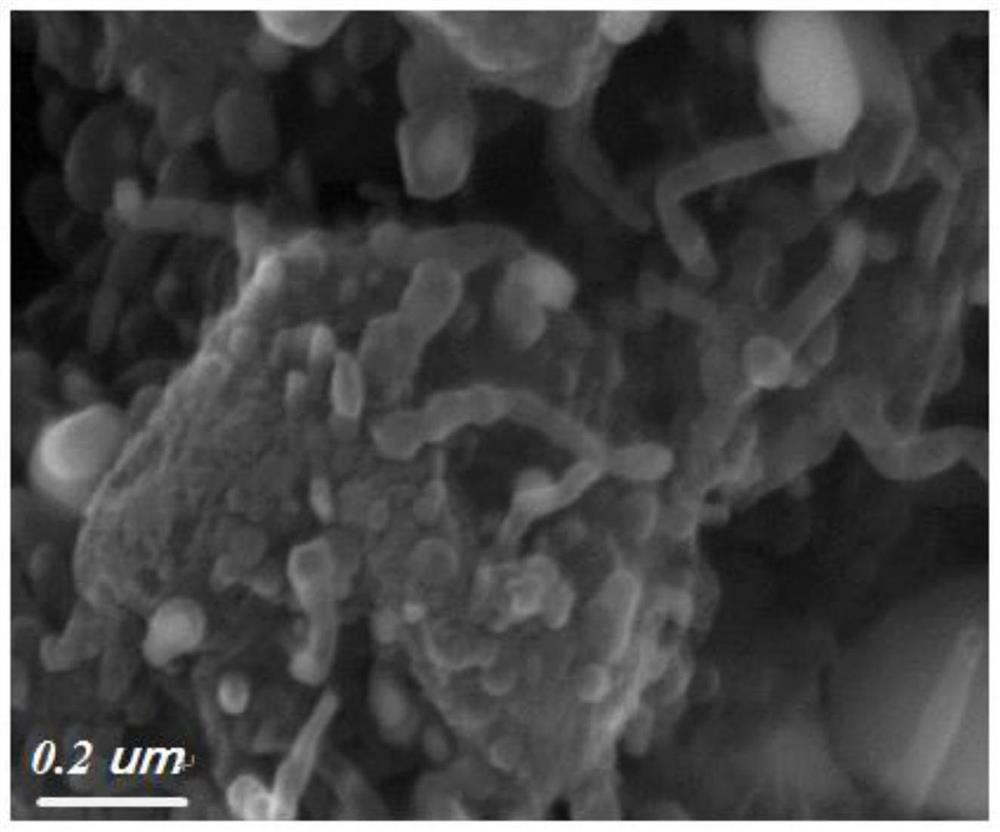

[0044] (4) After the solid C is ground evenly, it is placed in a tube furnace and calcined in ascending order; the first-stage holding temperature is 300°C, the heating r...

Embodiment 2

[0049] (1) 1.455g cobalt nitrate hexahydrate and 0.139g ferrous sulfate heptahydrate are added to a container filled with N2 bubbling for 20

[0050] After 1 min, in a three-necked flask of 100mL methanol solution, the solution was sealed, and magnetically stirred to obtain solution A after the solid was completely dissolved;

[0051] (2) Add 12.016g of dimethylimidazole solid into a beaker containing 150ml of methanol. Magnetic stirring, after the solution is completely dissolved, pour nitrogen into solution A in (1) after bubbling for 20 minutes, and continue stirring for 1 hour to obtain solution B;

[0052] (3) The solution B was left standing at room temperature for 18 hours, filtered, washed with distilled water and methanol, and dried in a vacuum oven at 70°C for 24 hours to obtain solid C;

[0053] (4) Grinding the solid C evenly and placing it in a tube furnace for calcining with increasing temperature. In the first stage, the holding temperature is 300°C, the heati...

Embodiment 3

[0060] (1) Add 1.455g of cobalt nitrate hexahydrate and 0.209g of ferrous sulfate heptahydrate to a container filled with N 2 Bubble 20

[0061] In the three-neck flask of 200mL methanol solution after 1 min, the solution was sealed, and magnetically stirred to obtain solution A after the solid was completely dissolved;

[0062] (2) Take 14.420 g of solid dimethylimidazole and add it to a beaker containing 100 ml of methanol. Magnetic stirring, after the solution is completely dissolved, pour nitrogen into solution A in step (1) after bubbling for 20 minutes, and continue stirring for 1 hour to obtain solution B;

[0063] (3) The solution B was left standing at room temperature for 18 hours, filtered, washed with distilled water and methanol, and dried in a vacuum oven at 70°C for 24 hours to obtain solid C;

[0064] (4) Grinding the solid C evenly and placing it in a tube furnace for calcining with increasing temperature. In the first stage, the holding temperature is 300°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com