Preparation method of fried abelmoschus esculentus with low oil content

A technology of coffee amber and oil content, which is applied to the functions of food ingredients, food preservation, and fruit and vegetable preservation. The effects of frying time, reducing harmful substances, and clear appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

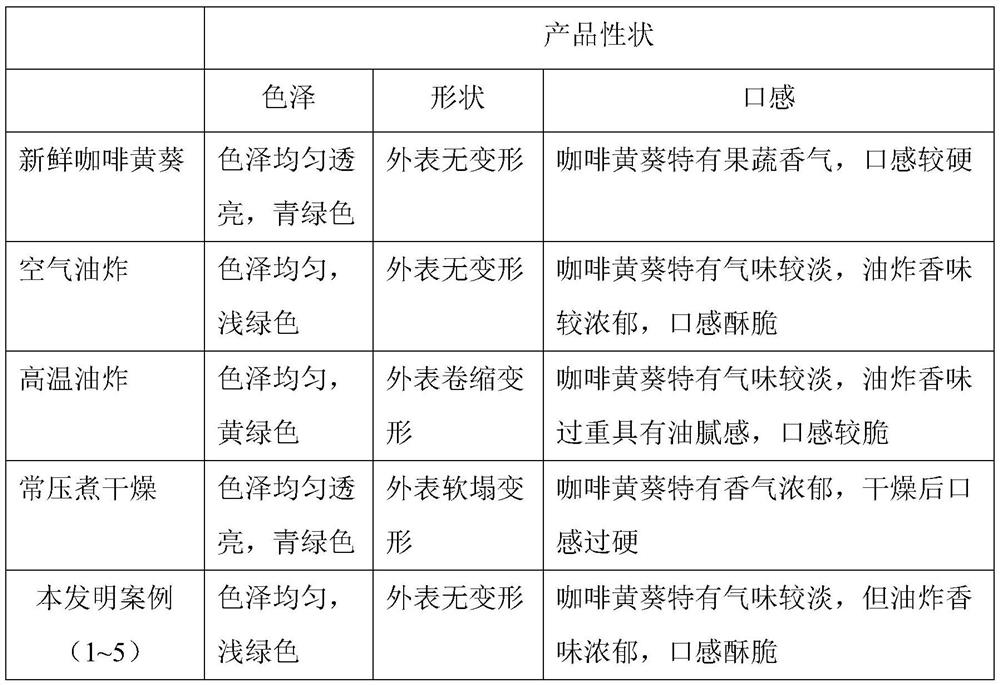

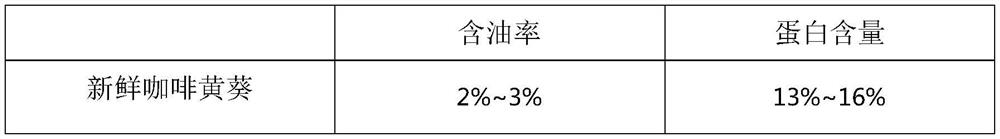

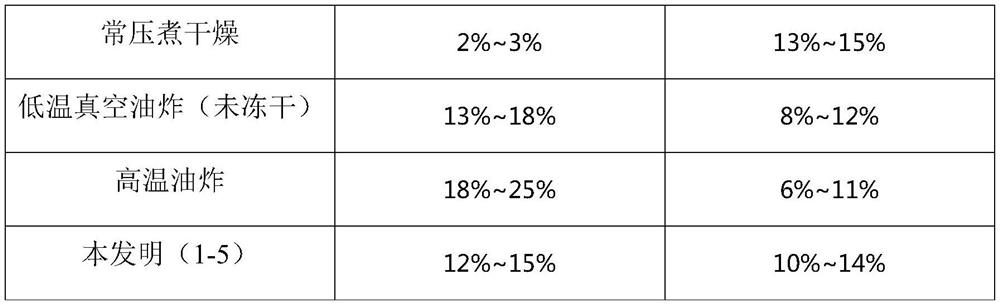

Examples

Embodiment 1

[0034] (1) Finishing treatment: put the cleaned coffee amber sunflower into 98°C hot water for 5 minutes, place it in cold water at 5°C for cooling, and the cooling time is 5 minutes;

[0035] (2) Dehydration treatment: put the cooled coffee yellow into a centrifugal dehydration device for dehydration, the dehydration time is 3min, and the centrifugal speed is 400r / min;

[0036] (3) Impregnation treatment: put the frozen coffee ambrette into the prepared impregnation solution for vacuum impregnation, the impregnation temperature is 40°C, the impregnation time is 60min, the vacuum degree is 900hpa, the impregnation time is 120min, the impregnation temperature is 40°C, drained, into the freezer;

[0037] The steeping liquid comprises the following components according to weight percentage: 25% maltodextrin solution, 10% maltose syrup, 0.8% sodium chloride, 0.5% sodium bicarbonate, 0.3% sodium citrate, and the balance is water;

[0038] (4) Low-temperature freezing treatment: th...

Embodiment 2

[0043] (1) Finishing treatment: put the cleaned coffee amber in hot water at 90°C for 3 minutes, then place it in cold water at 5°C for cooling, and the cooling time is 2 minutes;

[0044] (2) Dehydration treatment: put the cooled coffee yellow into a centrifugal dehydration device for dehydration, the dehydration time is 3min, and the centrifugal speed is 400r / min;

[0045] (3) Impregnation treatment: the frozen coffee ambrette is vacuum-impregnated in the prepared impregnation solution, the impregnation temperature is 50°C, the impregnation time is 120min, the vacuum degree is 900hpa, the impregnation time is 120min, the impregnation temperature is 40°C, drained, into the freezer;

[0046] The steeping liquid comprises the following components according to weight percentage: 25% maltodextrin solution, 10% maltose syrup, 0.8% sodium chloride, 0.5% sodium bicarbonate, 0.3% sodium citrate, and the balance is water;

[0047] (4) Low-temperature freezing treatment: the soaked an...

Embodiment 3

[0052] (1) Finishing treatment: put the cleaned coffee amber in hot water at 95°C for 2 minutes, then place it in cold water at 5°C for cooling, and the cooling time is 2 minutes;

[0053] (2) Dehydration treatment: put the cooled coffee yellow into the centrifugal dehydration equipment for dehydration, the dehydration time is 3min, and the centrifugal speed is 450r / min;

[0054] (3) Impregnation treatment: put the frozen coffee ambrette into the prepared impregnation solution for vacuum impregnation, the impregnation temperature is 40°C, the impregnation time is 120min, the vacuum degree is 900hpa, the impregnation time is 120min, the impregnation temperature is 40°C, drain, into the freezer;

[0055] The steeping liquid comprises the following components according to weight percentage: 25% maltodextrin solution, 10% maltose syrup, 0.8% sodium chloride, 0.5% sodium bicarbonate, 0.3% sodium citrate, and the balance is water;

[0056] (4) Low-temperature freezing treatment: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com