Device and method for solvent DMSO rectification recovery process in carbon fiber production process

A production process, carbon fiber technology, applied in the field of carbon fiber processing, can solve the problems of intermittent operation, poor production environment, high energy consumption, etc., and achieve the effect of reducing waste gas disposal costs, avoiding waste water volume, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

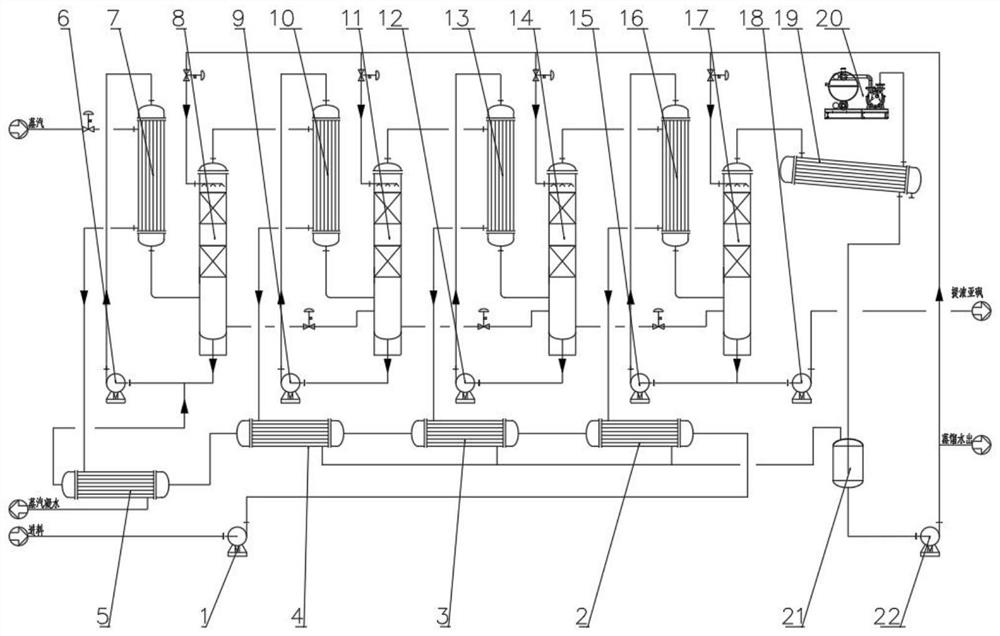

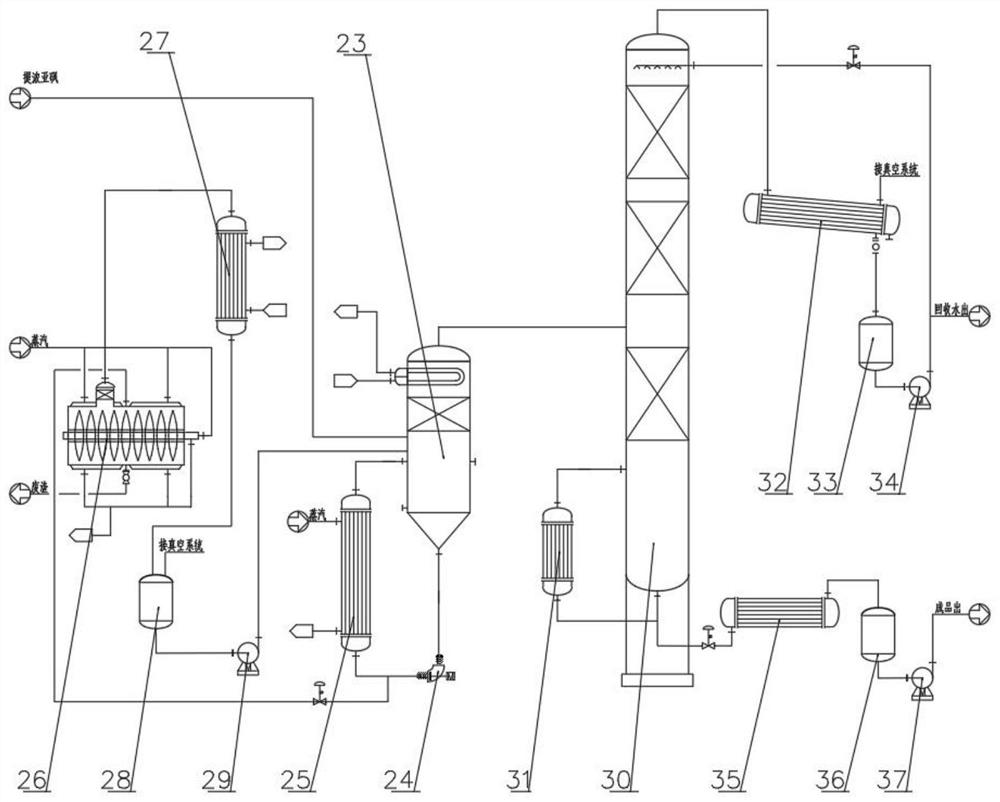

[0034] refer to Figure 1-2, a device and method for the solvent DMSO rectification recovery process in the carbon fiber production process, about 22% of the dilute DMSO aqueous solution is transported through the feed pump, and then passes through the first-stage preheater (the heat source is the condensed water of the four-effect evaporator), the second After the first-stage preheater (the heat source is the condensed water of the three-effect evaporator), the third-stage preheater (the heat source is the condensed water of the second-effect evaporator), and the fourth-stage preheater (the heat source is the condensed water of the raw steam of the first-effect evaporator), Enter the first-effect rectification tower, then the material is transported from the first-effect rectification tower to the top of the first-effect falling-film evaporator through the first-effect falling-film circulating pump, and the material is evenly distributed to the heat exchange through the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com