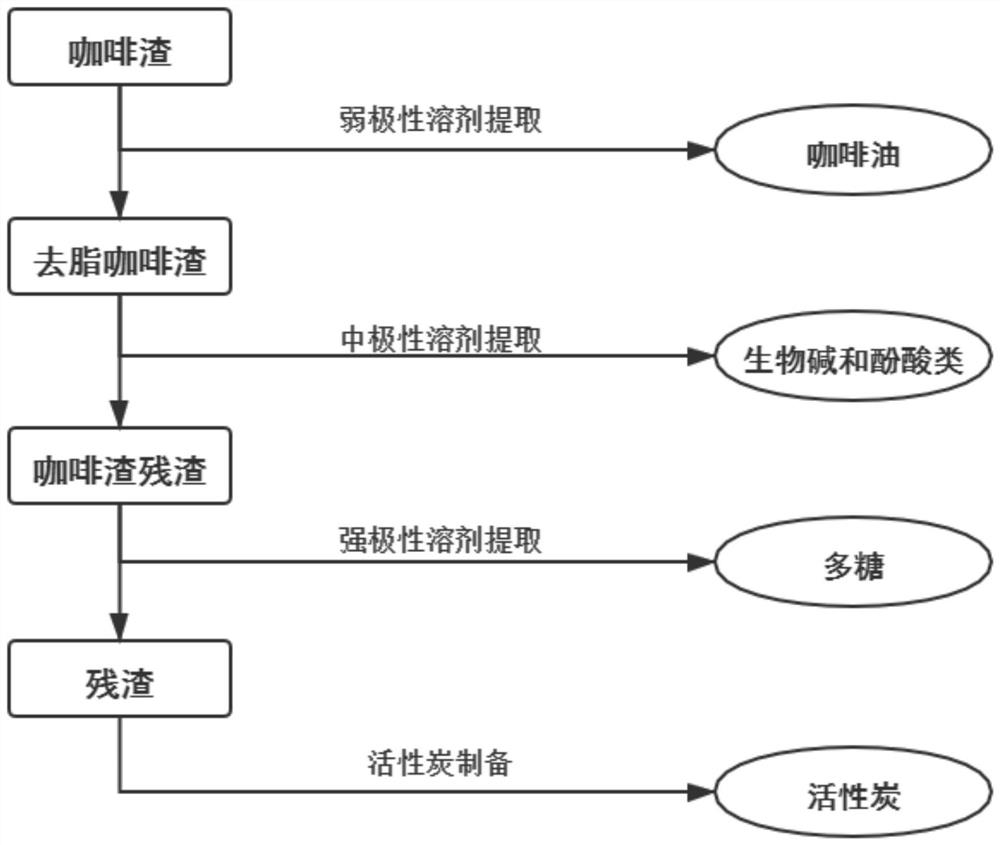

Comprehensive utilization process of coffee grounds

A technology of coffee grounds and processes, applied in the fields of extraction and separation of natural compounds and reuse of biomass wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 5.0 g of crushed dry coffee grounds powder, add 75 mL of petroleum ether, set the temperature of the water bath at 30 ° C, extract for 90 min, and extract by heating and reflux;

[0024] (2) After the extraction is completed, remove the residue by filtration, take 15 mL of petroleum ether to wash the residue and combine it with the extract, concentrate the filtrate to remove the solvent completely, and obtain 0.6265 g of coffee oil product, with an extraction rate of 12.53%, and dry the residue for future use.

Embodiment 2

[0026] (1) Weigh 5.0 g of crushed dry coffee grounds powder, add 75 mL of petroleum ether, set the temperature of the water bath at 70 ° C, extract for 150 min, and extract by heating and refluxing;

[0027] (2) After the extraction is completed, remove the residue by filtration, take 15 mL of petroleum ether to wash the residue and combine it with the extract, concentrate the filtrate to remove the solvent completely, and obtain 0.7415 g of coffee oil product, with an extraction rate of 14.83%, and dry the residue for future use.

Embodiment 3

[0029] (1) Weigh 5.0 g of crushed dry coffee grounds powder, add 75 mL of petroleum ether, set the temperature of the water bath at 50 ° C, extract for 210 min, and extract by heating and refluxing;

[0030] (2) After the extraction is completed, remove the residue by filtration, take 15 mL of petroleum ether to wash the residue and combine it with the extract, concentrate the filtrate to remove the solvent completely, and obtain 0.7460 g of coffee oil product with an extraction rate of 14.92%, and dry the residue for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap