Intelligent oil-water separation material as well as preparation method and application thereof

An oil-water separation and intelligent technology, which is applied in the field of materials, can solve the problems of inability to remove water-soluble pollutants in wastewater and cannot meet the requirements of water purification, etc., and achieve the effects of enhanced mechanical stability, low production cost and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

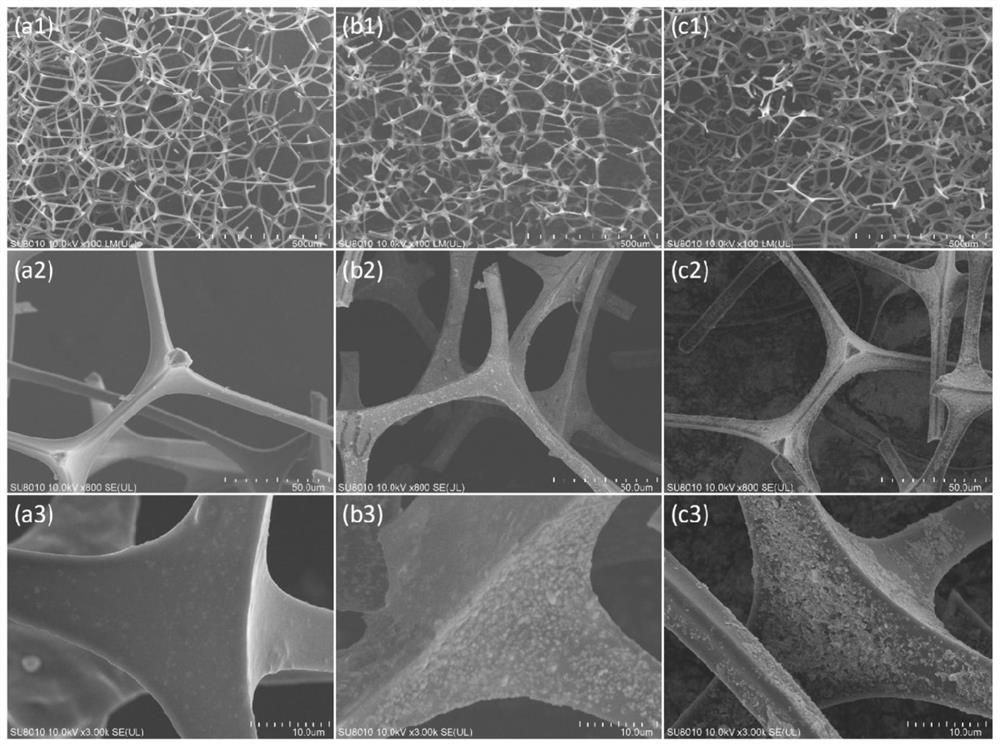

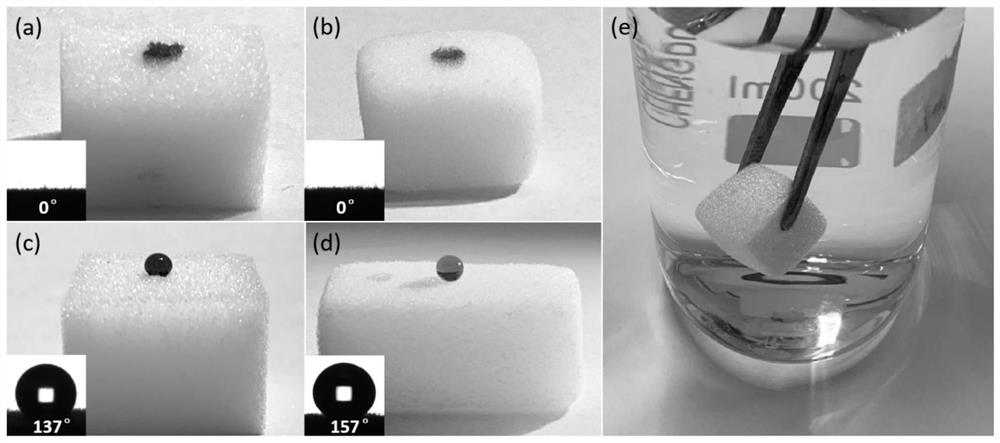

[0038] Example 1 An intelligent oil-water separation material S-BiOBr@MS

[0039] (1) The preparation method is as follows:

[0040] 1) Weigh 0.0485g of bismuth nitrate pentahydrate and add it to a mixed solution of 10mL of deionized water and 20mL of glycerol, ultrasonically treat it for 10min, and further stir the solution at room temperature until it is clear and transparent to obtain solution A.

[0041] Weigh 0.0119g of potassium bromide and dissolve it in 30mL of deionized water, stir until completely dissolved to obtain solution B.

[0042] 2) Immerse a 1cm×1cm×1cm melamine sponge MS in the solution B, so that the sponge absorbs the solution B completely.

[0043] Then, the remaining solution B was added dropwise to solution A with a dropper, and stirred while adding, and at the same time, the MS saturated with solution B was transferred to solution A, stirred for 1 h, and then aged at room temperature for 3 h. After the reaction, the sponge was taken out, washed once...

Embodiment 2

[0053] Example 2 Application of intelligent oil-water separation material S-BiOBr@MS in separating oil-water mixture

[0054] 1. In order to investigate the practical application of intelligent oil-water separation materials to collect oil spills, the situation of separating oil from oil-water mixture under natural conditions was simulated. Selective adsorption experiments were carried out by mixing n-hexane (light oil, stained with Sudan III) and chloroform (heavy oil, stained with Sudan IV) with water. The results are as follows: Figure 4 .

[0055] like Figure 4 In (a) to (c), the density of n-hexane is small, above the water phase, when the material is in contact with it, n-hexane is quickly sucked into the interior of the sponge, thereby realizing the static separation of n-hexane and water.

[0056] For comparison, such as Figure 4 In (d)-(f), chloroform sinks under the water phase due to its high density. When the material is in contact with chloroform, chloroform...

Embodiment 3

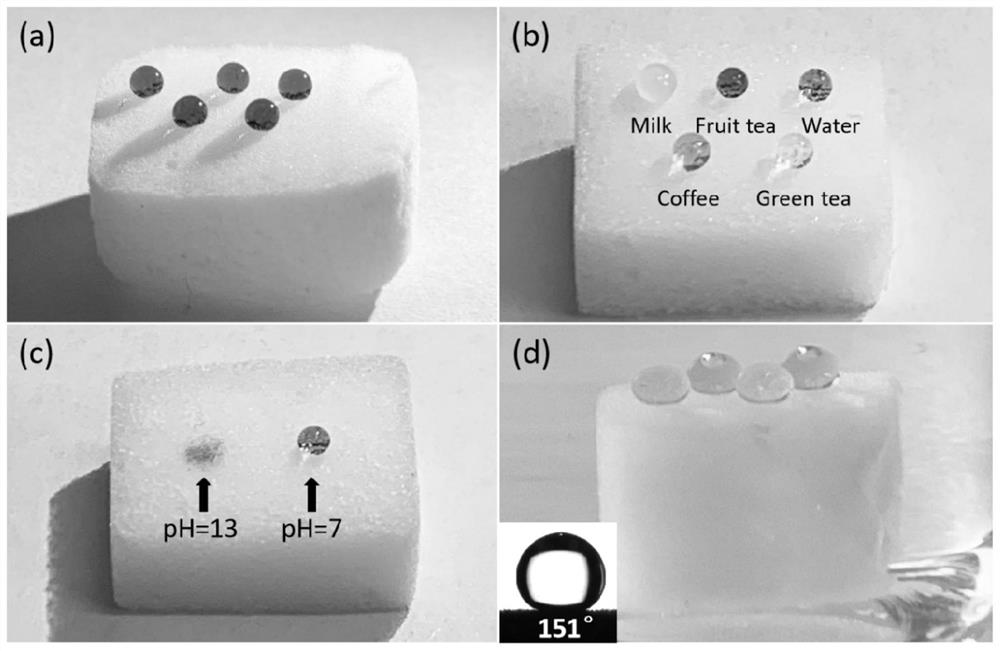

[0060] Example 3 Investigation of Mechanical Stability of Intelligent Oil-Water Separation Material S-BiOBr@MS

[0061] 1. The mechanical stability of the S-BiOBr@MS material was examined. like Figure 7 As shown in a, the wear experiment was carried out on the S-BiOBr@MS material; as Figure 7 As shown in b, the tensile test was carried out on the S-BiOBr@MS material; as Figure 7 As shown in c, the torsion experiment was performed on the S-BiOBr@MS material; as Figure 7 As shown in d, the pressing experiment was carried out on the S-BiOBr@MS material; as Figure 7 As shown in e, the water shock experiment was performed on the S-BiOBr@MS material. Each experiment was repeated many times, and the contact angle of S-BiOBr@MS material can still be kept above 150°, and the oil-water separation efficiency can still be kept above 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com