Water purification treatment system for high-iron-manganese-silicon water source

A technology of water purification and manganese-silicon, which is applied in the field of water treatment, can solve the problems of low removal rate of silicon ions, no self-cleaning system, and drop of effluent pH value, so as to meet engineering design requirements, simple water treatment process, and The effect of small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

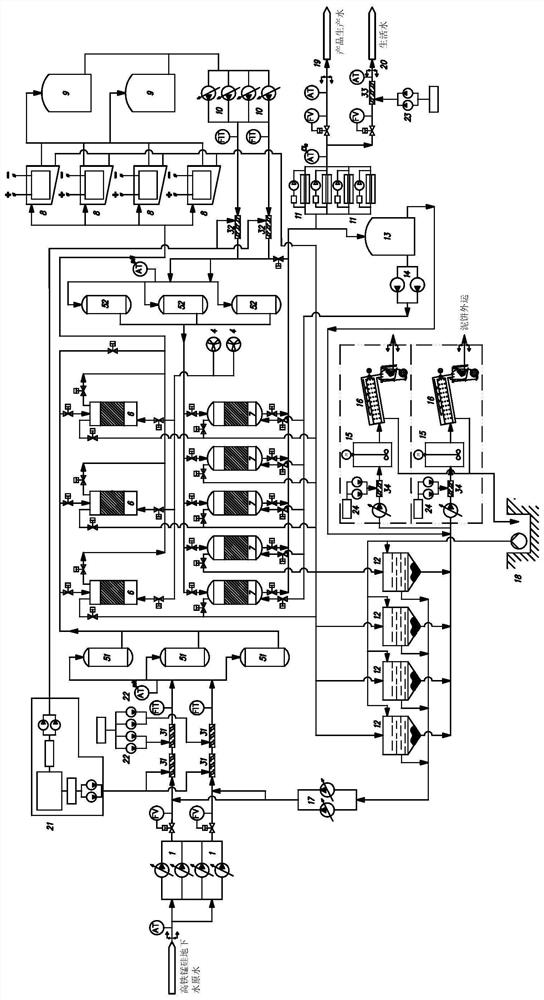

[0031] The water purification treatment system of the high iron manganese silicon water source of embodiment, as figure 1 As shown, it includes a primary lift pump 1, a primary pipeline mixer 31, a primary contact tank 51, an aeration contact oxidizer 6, an electrocoagulation facility 8, an electrocoagulation outlet tank 9, a secondary lift pump 10, and a secondary pipeline Mixer 32, secondary contact tank 52, filter 7, backwash unit, ultraviolet sterilizer 11, dosing unit, clarified water tank 12 and sludge dehydration unit, backwash unit includes backwash water tank 13 and booster pump 14. The dosing unit includes a sodium hypochlorite dosing device 21, a first sodium hydroxide dosing device 22, a second sodium hydroxide dosing device 23 and a flocculant dosing device 24, and the sludge dehydration unit includes a sludge mixing tank 15 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com