A kind of water-based uv paint and preparation method thereof

A water-based and modified technology, applied in the field of UV paint manufacturing, can solve the problems of insufficient adhesion and hardness of water-based UV paint, slow drying speed, insufficient water resistance of the paint film, etc., to shorten the UV curing time, promote dispersion, shorten the Effect of UV curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

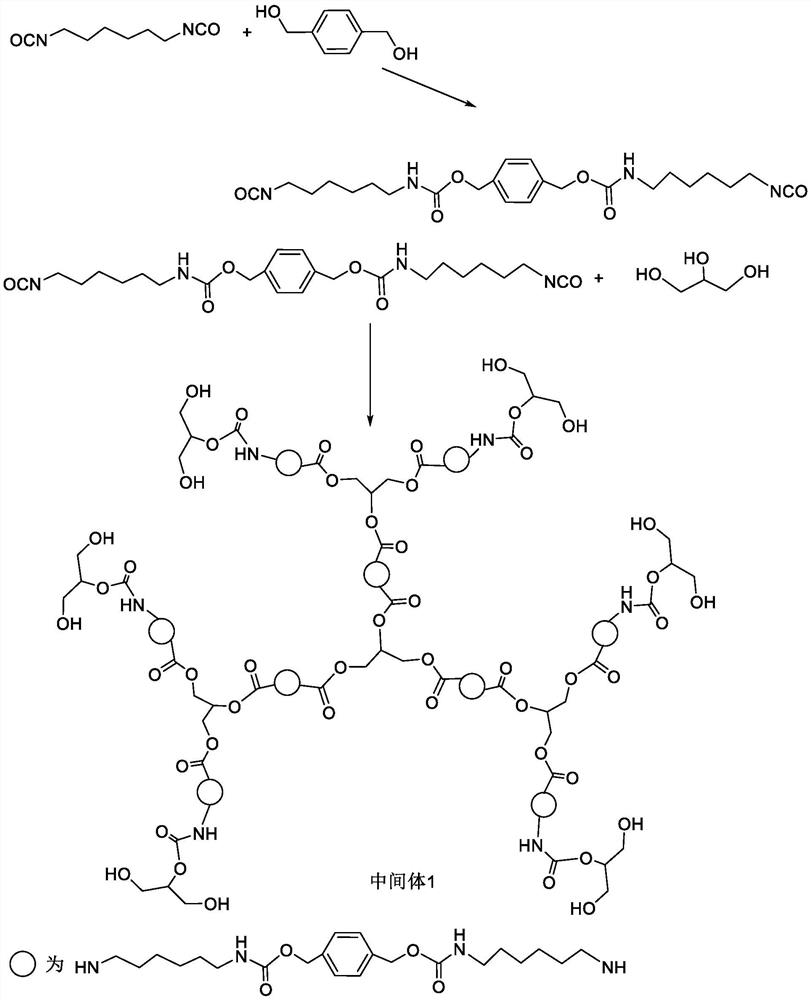

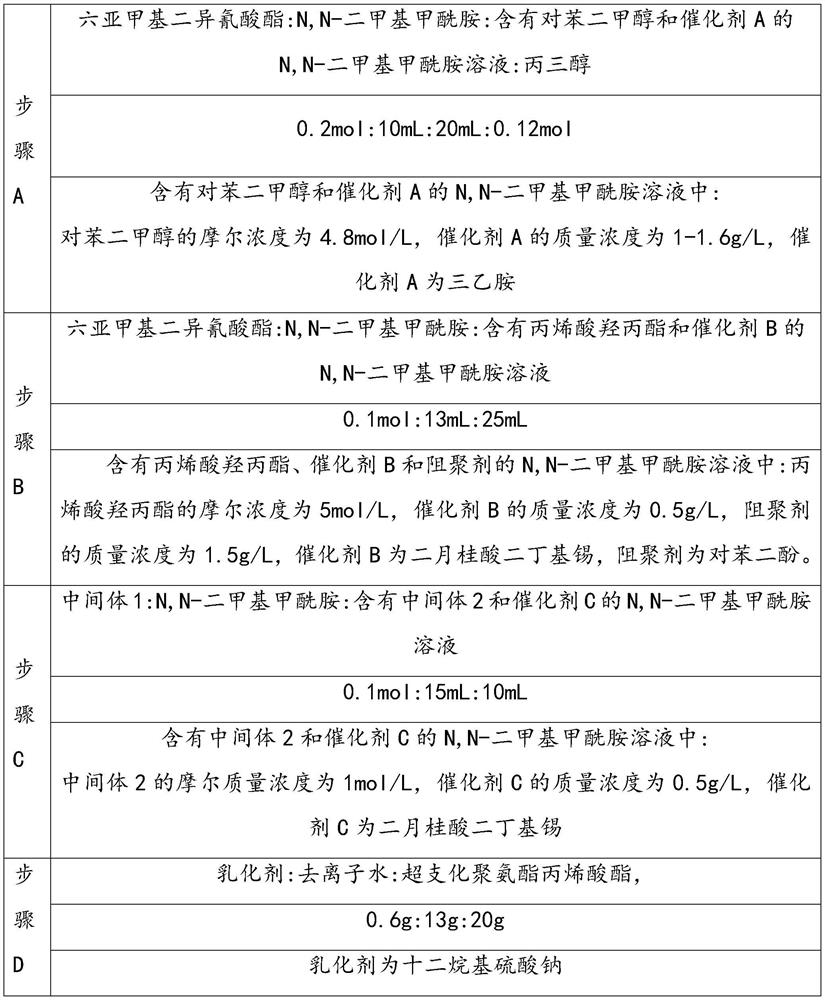

[0041] Hyperbranched polyurethane acrylate emulsion is made through the following steps:

[0042] Step A: Add hexamethylene diisocyanate and N,N-dimethylformamide into a four-necked flask equipped with a stirring bar, a reflux condenser and nitrogen gas, and stir evenly. Heat the temperature of the reaction system to 73°C in the pot, and then use a constant pressure dropping funnel to drop the N,N-dimethylformamide solution containing terephthalic acid and catalyst A. After the addition, measure it every 20 minutes The NCO value of the reaction system, when the NCO value reaches 15.01%, the temperature of the reaction system is heated to 77 ° C, and then the glycerol is added dropwise with a constant pressure dropping funnel. After the addition, the reaction system is measured every 20 minutes. NCO value, when the NCO value is lower than 1%, cool to room temperature, wash with water 3 times, and dry in a vacuum oven at 40°C to obtain intermediate 1;

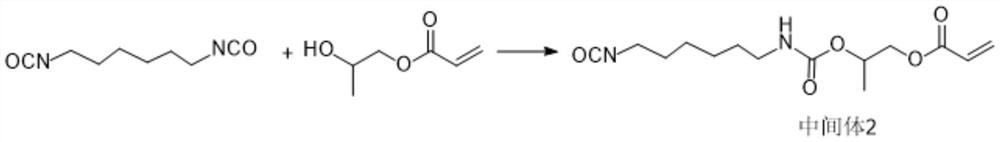

[0043] Step B. Add hexam...

Embodiment 2

[0050] The hyperbranched urethane acrylate emulsion is made through the following steps. With reference to the preparation steps of Example 1, the raw materials in each step and the amount of each raw material are shown in Table 2.

[0051] Table 2

[0052]

Embodiment 3

[0054] The hyperbranched urethane acrylate emulsion is made through the following steps. With reference to the preparation steps of Example 1, the raw materials in each step and the amount of each raw material are shown in Table 3.

[0055] table 3

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com