A kind of ni-co-fe-b system eutectic high-entropy alloy and its preparation method and application

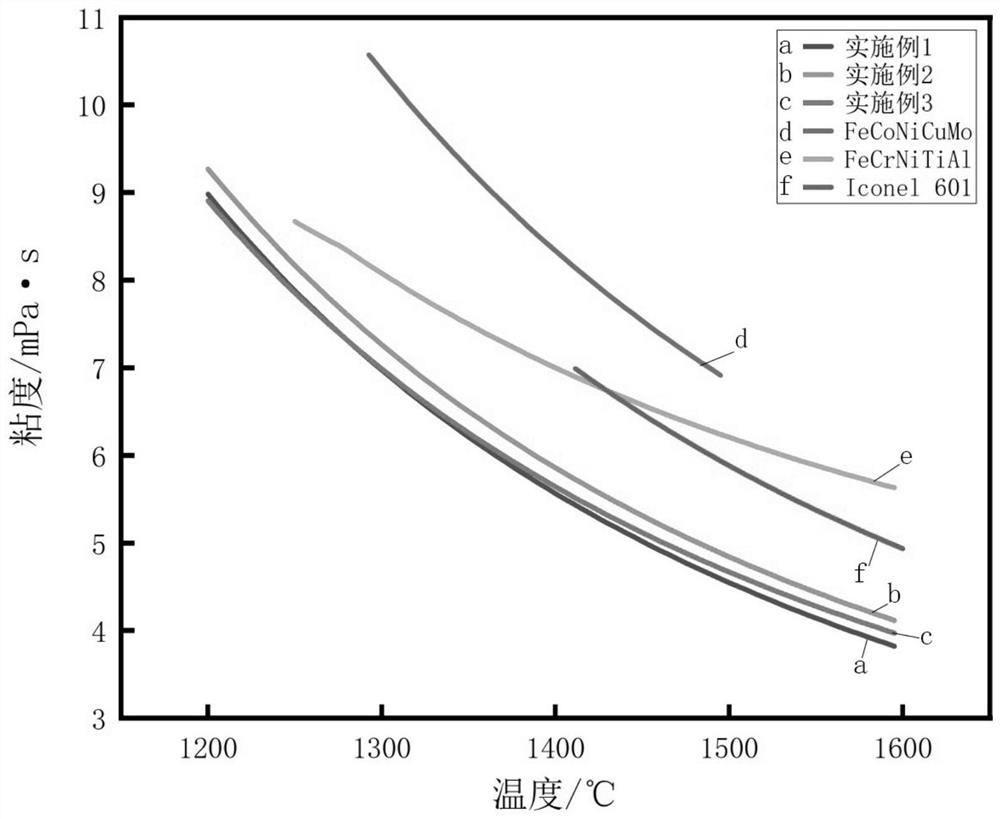

A ni-co-fe-b, high-entropy alloy technology, applied in the field of high-entropy alloys, can solve the problems of poor fluidity and castability of high-entropy alloys, and achieve the effects of good fluidity, excellent casting performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

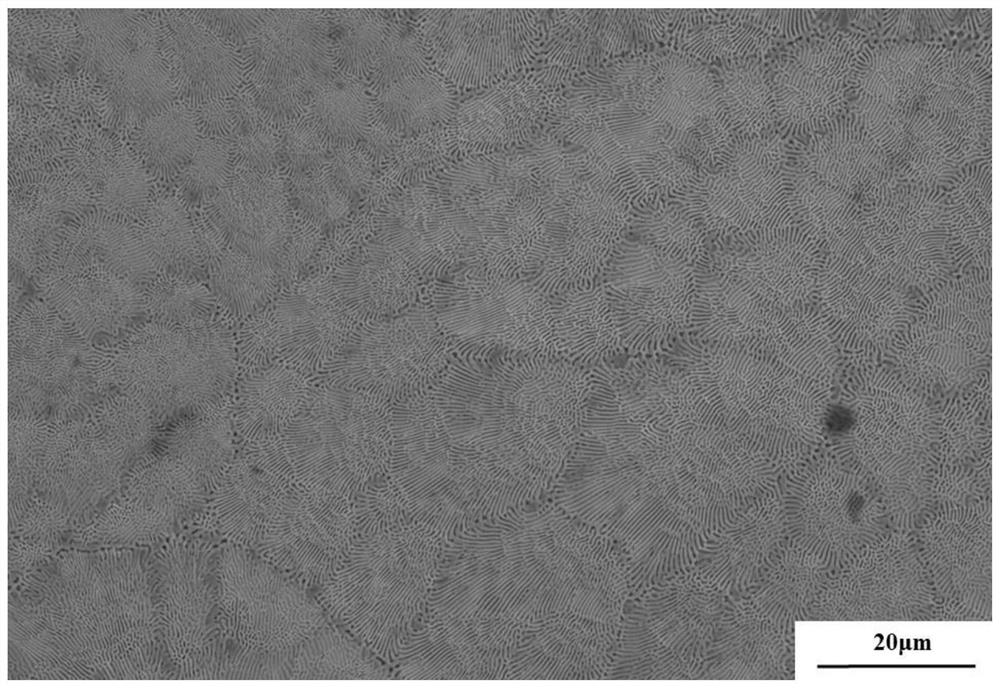

Image

Examples

preparation example Construction

[0026] A method for preparing a Ni-Co-Fe-B eutectic high-entropy alloy, comprising the following steps:

[0027] (1) Use physical or chemical methods to remove the oxide skin on the surface of the alloy raw materials, and use ethanol to ultrasonically clean the alloy raw materials for 15 to 20 minutes; wherein, the physical method is one or more of sandpaper grinding, sandblasting, and laser removal, and the chemical method is One or more of immersion pickling method, spray pickling method, and acid paste rust removal method; the purity of the alloy raw material is 99.5-100%.

[0028] (2) according to the ratio of each component of the eutectic high-entropy alloy, the alloy raw material is put into the quartz test tube in the suspension melting furnace;

[0029] (3) Wait until the vacuum degree of the suspension smelting furnace is pumped to 6×10 -3 Pa~5×10 -3 Argon is filled after Pa, and the pressure in the furnace reaches 0.05-0.06MPa.

[0030] (4) Melting to obtain eute...

Embodiment 1

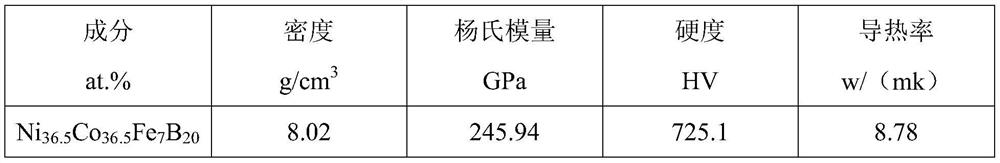

[0035] A eutectic high-entropy alloy whose components are designed as Ni in molar ratio a co b Fe c B d m e , M is a trace element. Among them, a=36.5%, b=36.5%, c=7%, d=20%, e=0%, namely Ni 36.5 co 36.5 Fe 7 B 20 .

[0036] Eutectic high entropy alloy Ni 36.5 co 36.5 Fe 7 B 20 The preparation method comprises the following steps:

[0037] (1) Remove the oxide skin on the surface of the raw material by sandpaper grinding, and use ethanol to ultrasonically clean the alloy raw material for 15 minutes;

[0038] (2) According to the eutectic high entropy alloy Ni 36.5 co 36.5 Fe 7 B 20 Put the alloy raw material into the quartz test tube in the suspension melting furnace;

[0039] (3) To be vacuumed to 6 × 10 -3 Argon is filled after Pa, and the pressure in the furnace reaches 0.05MPa;

[0040] (4) Smelting to obtain eutectic high-entropy alloy Ni with uniform structure composition 36.5 co 36.5 Fe 7 B 20 .

[0041] The properties of the alloy prepared unde...

Embodiment 2

[0045] A eutectic high-entropy alloy whose components are designed as Ni in molar ratio a co b Fe c B d m e , M is a trace element. Among them, a=37.5%, b=37.5%, c=7%, d=18%, e=0%, namely Ni 37.5 co 37.5 Fe 7 B 18 .

[0046] Eutectic high entropy alloy Ni 37.5 co37.5 Fe 7 B 18 The preparation method comprises the following steps:

[0047] (1) Remove the oxide skin on the surface of the raw material by sandpaper grinding, and use ethanol to ultrasonically clean the alloy raw material for 20 minutes;

[0048] (2) According to the eutectic high entropy alloy Ni 37.5 co 37.5 Fe 7 B 18 Put the alloy raw material into the quartz test tube in the suspension melting furnace;

[0049] (3) To be vacuumed to 6 × 10 -3 Argon is filled after Pa, and the pressure in the furnace reaches 0.05MPa;

[0050] (4) Smelting to obtain a eutectic high-entropy alloy with uniform composition.

[0051] The properties of the alloys prepared under the above-mentioned alloy components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com