Preparation method of lithium iron phosphate battery positive electrode material

A lithium iron phosphate battery and lithium iron phosphate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsuitable for high rate charge and discharge, poor conductivity, etc., and achieve high charge and discharge performance and good rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

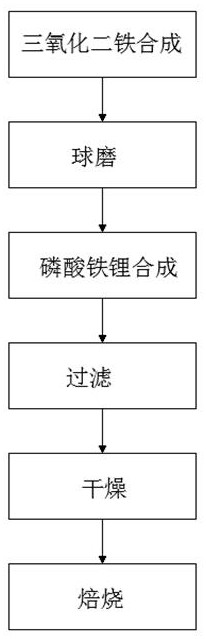

[0021] The invention provides a method for preparing a positive electrode material of a lithium iron phosphate battery, comprising the following steps:

[0022] (1) dissolving ferric chloride in ethylene glycol, adding sodium acetate and polyethylene glycol, heating; cooling to obtain ferric oxide; oxidizing ferric oxide to nano ferric oxide particles;

[0023] (2) Ball milling: Mix lithium acetate, nanometer ferric oxide, and ammonium dihydrogen phosphate in a molar ratio of Li:Fe:P=1:1:1 and mix with carbon source for ball milling; the ball milling time is 4-6 hours .

[0024] (3) Synthesis of lithium iron phosphate: under protective gas, the powder in step (2) is sintered, and the carbon-coated lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com