Method for preparing anode foil of aluminum electrolytic capacitor by means of cold rolling machine

A technology for aluminum electrolytic capacitors and anode foils, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as uneven thickness of sintered film, and achieve the effect of improving performance and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

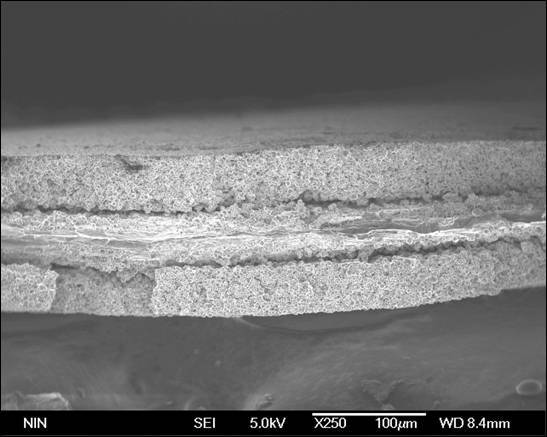

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] Step 1, adding a solvent, a binder and a dispersant to the aluminum raw material and then stirring to obtain an aluminum raw material slurry; the aluminum raw material is aluminum powder; the particle size of the aluminum powder is less than 20 μm, and the mass purity is greater than 99.99%; The solvent is terpineol, the binder is ethyl cellulose, and the dispersant is lecithin, wherein the mass ratio of terpineol, ethyl cellulose and lecithin is 97:3:1;

[0032] Step 2, coating the aluminum raw material slurry obtained in step 1 on the surface of the aluminum foil substrate, and then performing drying treatment to obtain the dried and coated aluminum foil substrate; the aluminum foil substrate is subjected to deoxidation film treatment before coating, and the obtained The process of removing the oxide film is soaking in a NaOH solution with a mass concentration of 0.1%; the thickness of the aluminum foil substrate ...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] Step 1, adding a solvent, a binder and a dispersant to the aluminum raw material and then stirring to obtain an aluminum raw material slurry; the aluminum raw material is aluminum powder; the particle size of the aluminum powder is less than 20 μm, and the mass purity is greater than 99.99%; Described solvent is ethylene glycol and terpineol, and described binder is ethyl cellulose, and described dispersion agent is lecithin, and wherein the mass ratio of ethylene glycol, terpineol, ethyl cellulose and lecithin is 10:85:5:1;

[0042] Step 2, coating the aluminum raw material slurry obtained in step 1 on the surface of the aluminum foil substrate, and then performing drying treatment to obtain the dried and coated aluminum foil substrate; the aluminum foil substrate is subjected to deoxidation film treatment before coating, and the obtained The process of removing the oxide film is soaking in a NaOH solution with a ...

Embodiment 3

[0049] This embodiment includes the following steps:

[0050] Step 1. Add solvent, binder and dispersant to the aluminum raw material and then stir to obtain aluminum raw material slurry; the aluminum raw material is aluminum powder and / or aluminum alloy powder; the particles of aluminum powder and aluminum alloy powder The diameters are all less than 20 μm, and the mass purity is greater than 99.99%; the solvent is terpineol, the binder is ethyl cellulose, and the dispersant is lecithin, wherein terpineol, ethyl cellulose and egg The mass ratio of phospholipids is 96:4:1;

[0051] Step 2, coating the aluminum raw material slurry obtained in step 1 on the surface of the aluminum foil substrate, and then performing drying treatment to obtain the dried and coated aluminum foil substrate; the aluminum foil substrate is subjected to deoxidation film treatment before coating, and the obtained The process of removing the oxide film is soaking in a NaOH solution with a mass concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com