Siloxane-terminated polymer homopolymerization reaction preparation method and moisture-curable composition

A polymerization reaction and polymer technology, applied in the field of materials, can solve problems affecting the storage stability of siloxane-terminated polymers, the degradation of isocyanate-based siloxane of the blocking agent, and the high viscosity of siloxane-terminated polymers. , to achieve excellent storage stability, reduction of capping side reaction products, and high hydrolytic crosslinking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Embodiment 1: Preparation of siloxane-terminated polymer (P) by homopolymerization method

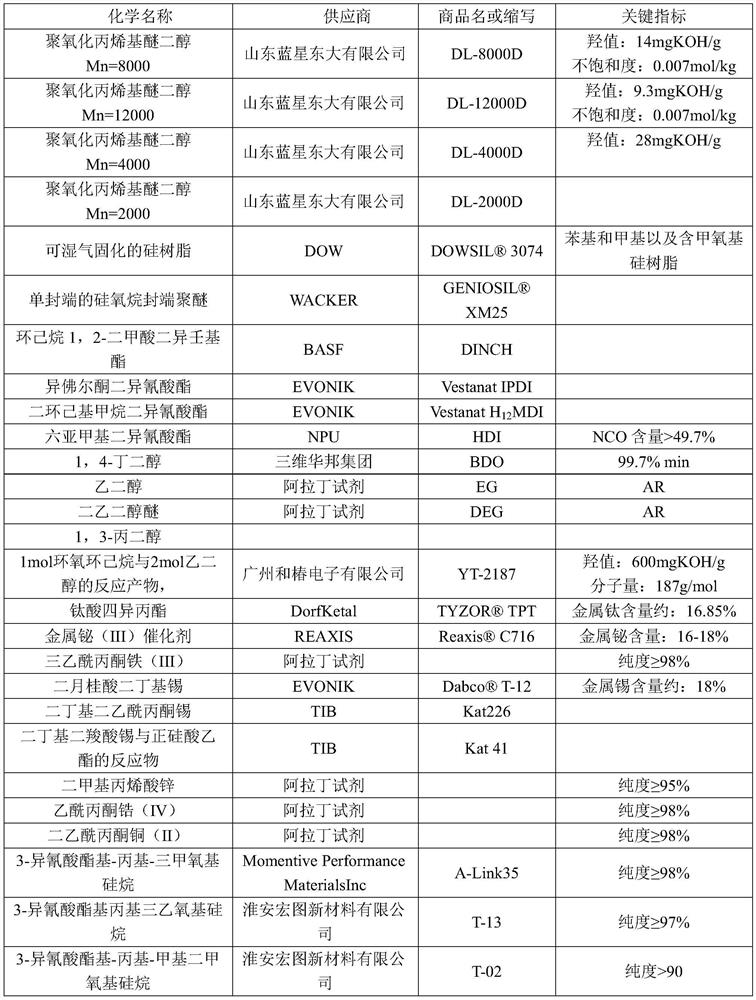

[0104] Dehydrate 3500g of pre-dehydrated DL-12000D polyether polyol (120°C with vacuum stirring for 2 hours, and cool to room temperature with N 2 protection), add in a 5L four-necked flask (respectively with anchor stirrer port, thermometer port, vacuum / nitrogen port, feeding port), and then add 2.0g metal-containing titanium catalyst ( TPT) and 1.5g metal-containing bismuth (III) catalyst ( C716), stirring and vacuum degassing, using N 2 Puncture the vacuum and replace with N 2 protection, add 130.0gIPDI, at N 2 After stirring evenly under protection, heat in a water bath until the temperature of the material is 80 to 85°C, and continue to pass N 2 Protect and maintain the reaction for 2 hours.

[0105] Sampling shall be carried out by titration method to detect the isocyanate content of the prepolymer. Stop heating until the isocyanate content reaches 0.67%. Continue co...

Embodiment 2

[0111] Embodiment 2: Preparation of siloxane-terminated polymer (P) by homopolymerization method

[0112] Dehydrate 3500g of pre-dehydrated DL-8000D polyether polyol (120°C with vacuum stirring for 2 hours, and cool to room temperature with N 2 protection), add 5L double planetary vacuum stirring tank (XGFJ-8L type planetary high-speed mixer, equipment manufacturer: Chengdu Silicon Special Automation Equipment Co., Ltd.), and then add 1.1g catalyst solution containing metal iron (acetylacetonate iron (III ), 50wt% pre-dissolved in toluene) and 0.9g metal-containing zinc catalyst (zinc dimethacrylate (II)), stirring and vacuum degassing, using N 2 Puncture the vacuum and replace with N 2 protection, adding 147.7gHDI, in N 2 After stirring evenly under protection, heat in a water bath until the temperature of the material is 80 to 85°C, and continue to pass N 2 Protect and maintain the reaction for 2 hours.

[0113] Sampling shall be carried out by titration to detect the is...

Embodiment 3

[0119] Embodiment 3: Preparation of siloxane-terminated polymer (P) by homopolymerization method

[0120] Dehydrate 40kg of pre-dehydrated DL-8000D polyether polyol (heated at 120°C with vacuum stirring for 2 hours, and cool to room temperature with N 2 protection), add 50L double planetary vacuum stirring tank (XGFJ-8L type planetary high-speed mixer, equipment manufacturer: Chengdu Silicon Special Automation Equipment Co., Ltd.), and then add 40.0g catalyst solution containing metal zirconium (zirconium acetylacetonate (IV ), 50wt% dissolved in acetone) and 20.0g metal-containing titanium catalyst (titanium tetraisopropoxide (IV), TPT), stirring and vacuum degassing, using N 2 Puncture the vacuum and replace with N 2 For protection, add 1.97kg Vestanat H 12 MDI, in N 2 After stirring evenly under protection, heat in a water bath until the temperature of the material is 80 to 85°C, and continue to pass N 2 Protect and maintain the reaction for 2 hours.

[0121] Sampling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com