Pigment yellow 138 easy to disperse in weak solvent and preparation method thereof

A pigment yellow and easy to disperse technology, applied in the field of pigments, can solve the problems of coating or printing difficulties, insufficient pigment color development, precipitation and agglomeration, etc., to reduce the formation of secondary aggregates, improve vividness, and particle size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

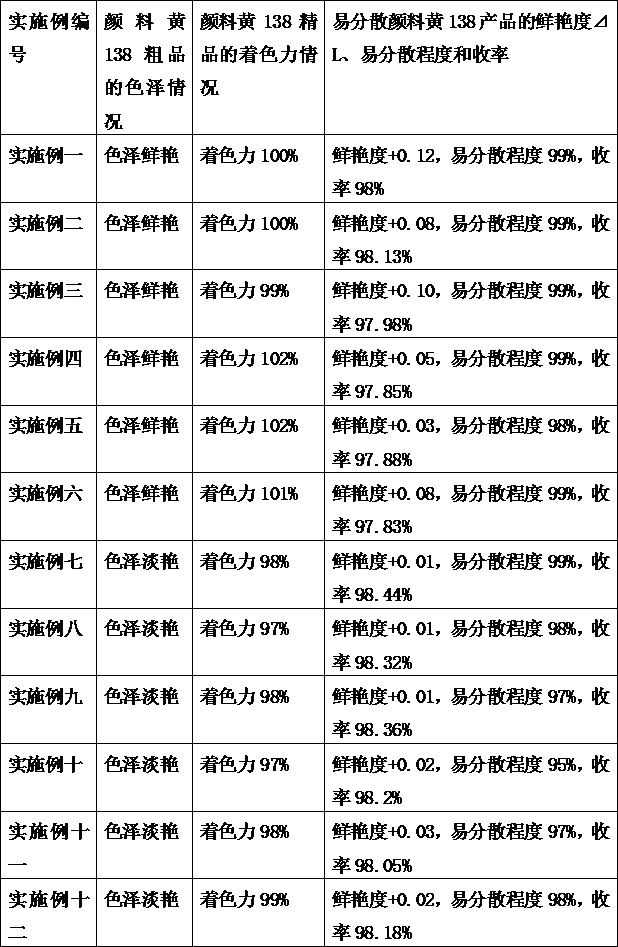

Examples

Embodiment 1

[0027] A preparation method for easily dispersible pigment yellow 138 in an environment-friendly polar solvent, comprising the following steps:

[0028] 1) Preparation of crude pigment yellow 138: put 3300kg of o-dichlorobenzene into the enamel reaction kettle, and then, at a speed of 130r / min, put in 412.5kg of tetrachlorophthalic anhydride, 50kg of zinc chloride and 8-aminoquinaldine in sequence 100kg, fill with nitrogen, slowly raise the temperature to 80°C, keep it warm for 1 hour, then raise the temperature to 180-200°C and keep it warm for 6 hours to get the crude pigment yellow 138 mixture; put the obtained pigment yellow 138 crude mixture into the vacuum paddle for drying In the machine, between 120-140°C, the vacuum degree is -0.08MPa to -0.1MPa to recover the solvent, and the crude product of Pigment Yellow 138 is obtained, and the quality of the crude product of Pigment Yellow 138 is 330kg;

[0029] 2) Preparation of Pigment Yellow 138 fine product: Add 3000kg of ac...

Embodiment 2

[0032] The difference between Example 2 and Example 1 is that in step 1) of Example 2, tin tetrachloride is used as the catalyst, and the mass of tin tetrachloride is 50 kg. The settings of other preparation process conditions are the same as those in Example 1.

Embodiment 3

[0034] The difference between Example 3 and Example 1 is that in step 1) of Example 3, the catalyst is anhydrous aluminum trichloride, and the mass of anhydrous aluminum trichloride is 50 kg. The settings of other preparation process conditions are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com