A geopolymer permeable brick and its preparation method and application

A technology of geopolymers and permeable bricks, applied in cement production, adsorption water/sewage treatment, etc., can solve problems such as overalkaline and alkali loss, achieve low cost, avoid alkali loss, and improve water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

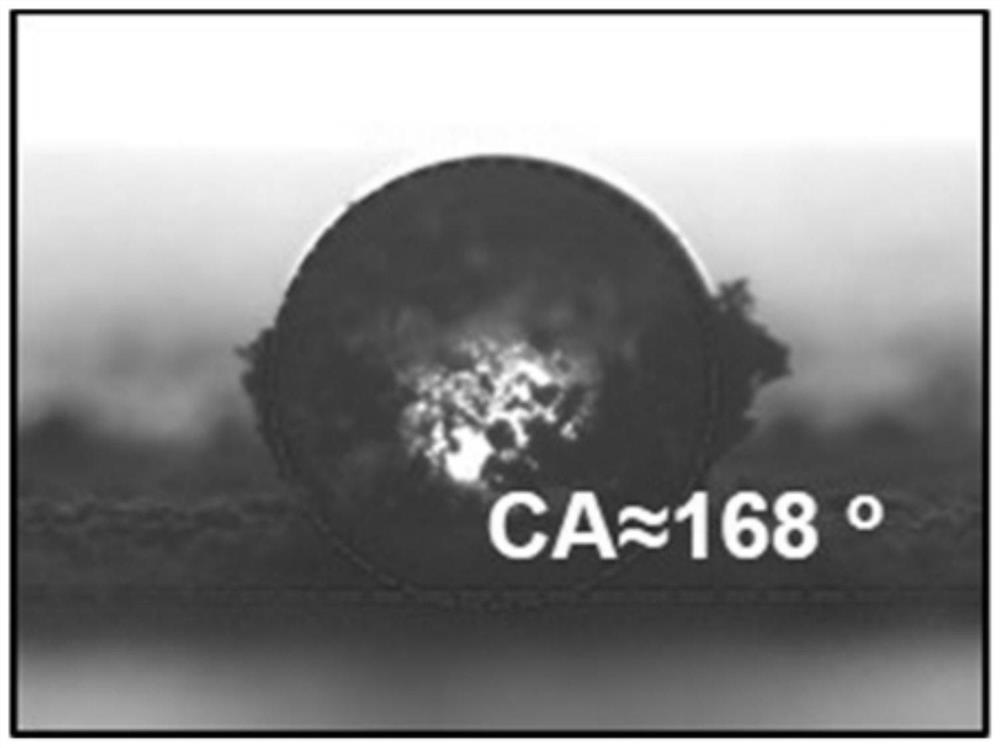

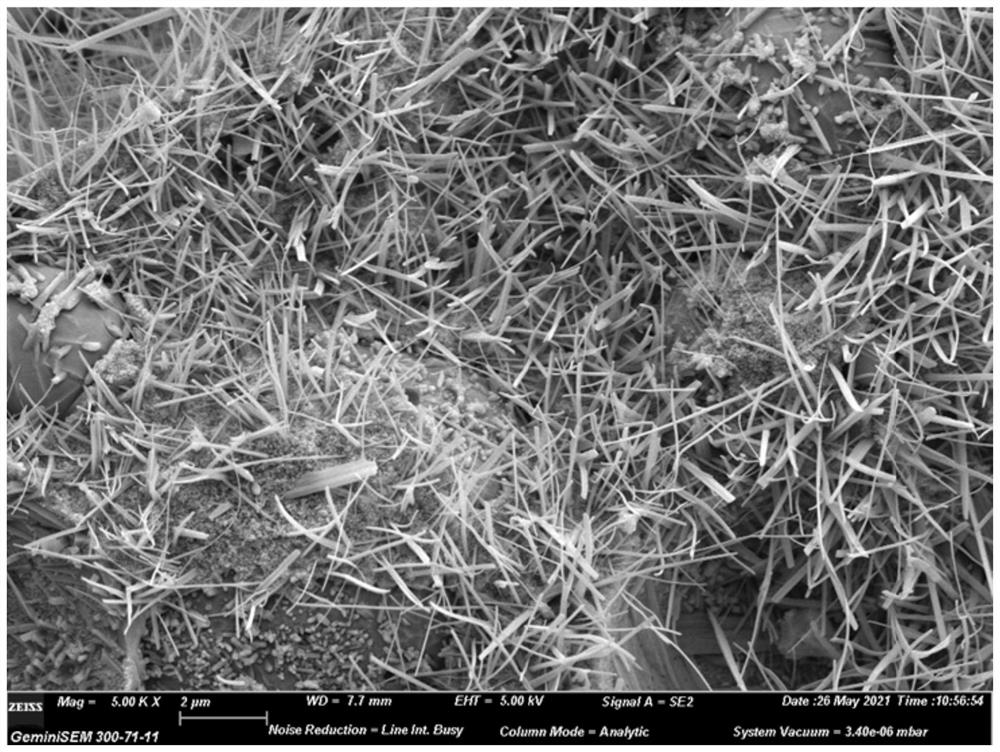

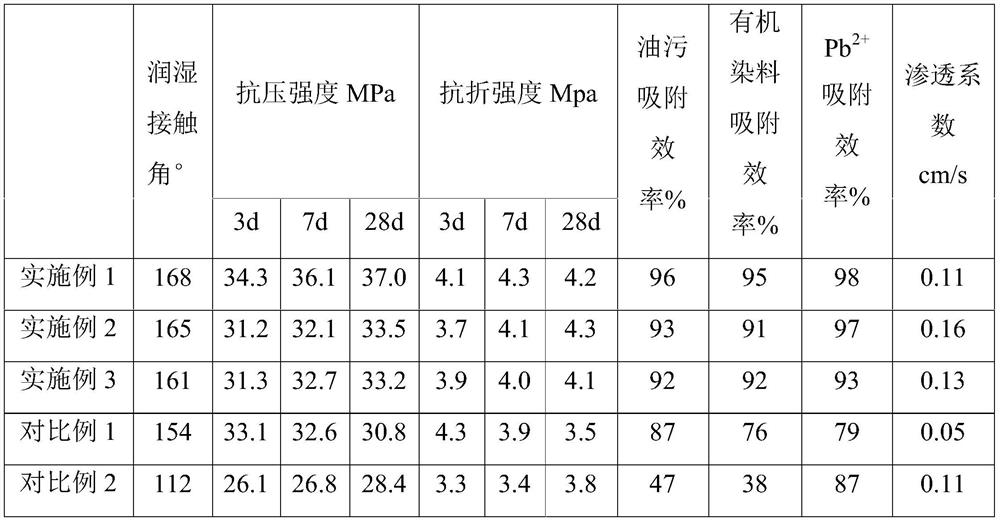

Examples

Embodiment 1

[0034] A method for preparing a geopolymer permeable brick, comprising the following process steps:

[0035] a. Stir and mix 22 parts of cementitious material and 78 parts of aggregate according to the mass ratio, then add an activator equivalent to 72% of the mass of the cementitious material, and mix evenly to obtain a mixing slurry;

[0036] Among them, the cementitious material includes: 20% blast furnace slag, 40% waste incineration ash and 40% metakaolin in terms of mass percentage, and the particle size of blast furnace slag, waste incineration ash and metakaolin is ≤45μm;

[0037] The aggregates used are artificial aggregates formed by crushing and screening construction solid waste; aggregates include coarse aggregates with a particle size of 5-10mm and fine aggregates with a particle size of 2-3mm, and the mass content of the coarse aggregate The mass content of fine aggregate is 70%.

[0038] The activator is obtained by mixing sodium water glass with a modulus of ...

Embodiment 2

[0044] A method for preparing a geopolymer permeable brick, comprising the following process steps:

[0045] a. Stir and mix 30 parts of cementitious material and 70 parts of aggregate according to the mass ratio, then add an activator equivalent to 75% of the mass of the cementitious material, and mix evenly to obtain a mixing slurry;

[0046] Among them, the cementitious material includes: 25% blast furnace slag, 50% waste incineration ash and 25% metakaolin in terms of mass percentage, and the particle size of blast furnace slag, waste incineration ash and metakaolin is ≤45μm;

[0047]The aggregate used is iron tailings slag; the aggregate includes coarse aggregate with a particle size of 5-10mm and fine aggregate with a particle size of 2-3mm, wherein the mass content of the coarse aggregate is 35%, and the mass content of the fine aggregate is The content is 65%.

[0048] The activator is obtained by mixing sodium water glass with a modulus of 3.5 and 10 mol / L sodium hyd...

Embodiment 3

[0053] A method for preparing a geopolymer permeable brick, comprising the following process steps:

[0054] a. Stir and mix 38 parts of cementitious material and 62 parts of aggregate according to the mass ratio, then add an activator equivalent to 80% of the quality of the cementitious material, and mix evenly to obtain a mixing slurry;

[0055] Among them, the cementitious material includes: 30% blast furnace slag, 60% waste incineration ash and 10% metakaolin in terms of mass percentage, and the particle size of blast furnace slag, waste incineration ash and metakaolin is ≤45μm;

[0056] The aggregate used is waste ceramics; the aggregate includes coarse aggregate with a particle size of 5-10mm and fine aggregate with a particle size of 2-3mm, wherein the mass content of the coarse aggregate is 40%, and the mass content of the fine aggregate is 60%.

[0057] The activator is obtained by mixing sodium water glass with a modulus of 3.6 and 11 mol / L sodium hydroxide solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com