Comprehensive utilization method of hydrogen-peroxide-process epichlorohydrin by-product

A technology of epichlorohydrin and by-products, which is applied in the field of comprehensive utilization of epichlorohydrin by-products in the hydrogen peroxide method, and can solve the problems of difficult processing and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add epichlorohydrin by-product 200g in the 500ml reaction flask with desolventizer, (composition is 2-CMP 68%, 1-CMP 18%, 3-chloro-1,2-propanediol 9%, low polymer 5 %), be warming up to 75 DEG C, start stirring, continuously dropwise add 470g40% hydroiodic acid, control dropwise time at 3hr, continue to insulate at reaction temperature for 2hr after dropping, and the reaction process collects light components by precipitation device;

[0023] Dehydrate the above materials under negative pressure, vacuum control -0.1Mpa, and the kettle temperature does not exceed 80°C;

[0024] Packing TiO in a fixed bed 2 Type solid superacid catalyst, the dehydrated material is passed into the fixed bed under the protection of nitrogen, the reaction temperature is controlled at 170 °C, and the mass space velocity is 1h -1 ;

[0025] The reaction material of fixed bed is carried out negative pressure rectification, vacuum control-0.1Mpa, kettle temperature is no more than 110 ℃, colle...

Embodiment 2~5

[0034] Investigate the hydroiodic acid consumption, have carried out different parameter experiments, all the other conditions are identical with embodiment 1. The data is as follows:

[0035] Example Hydroiodic acid: CMP ECH content (%) Yield (%) 2 1.0 99.2 89.5 3 1.05 99.4 92.8 1 1.065 99.7 93.2 4 1.10 99.7 93.0 5 1.2 99.7 90.2

[0036] It can be seen from the above table that the best dosage of hydroiodic acid is between 1.05 and 1.1.

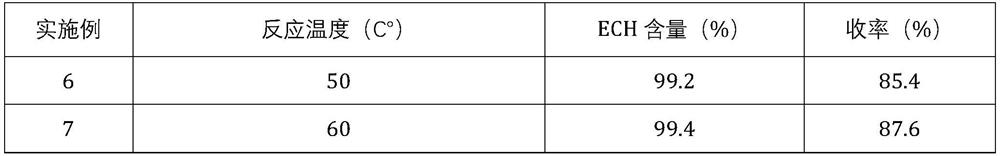

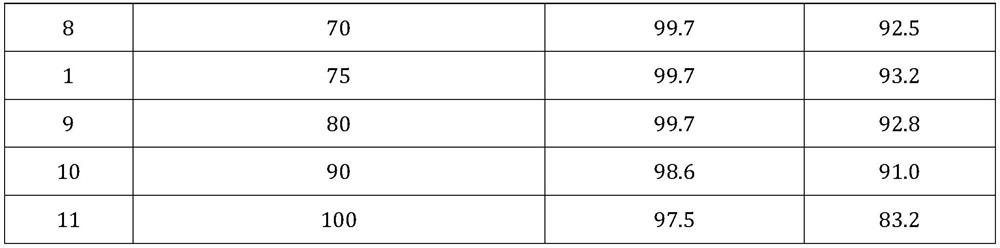

Embodiment 6~11

[0038] Investigate the influence of temperature of reaction in S1 on reaction, have carried out different parameter experiment, all the other conditions are identical with embodiment 1, and data are as follows:

[0039]

[0040]

[0041] It can be seen from the above table that the reaction temperature is 70-80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com