High-temperature-resistant water-based transfer coating and preparation method thereof

A transfer coating, high temperature resistant technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problem of difficult to achieve film appearance, drying speed, high temperature resistance and printing adaptability, poor film appearance, drying speed and printing adaptability Ideal, paint hardening and deterioration, etc., to improve the printing environment, easy peeling, good recoating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

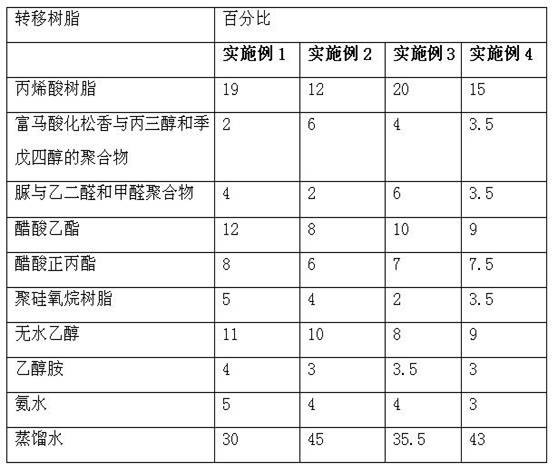

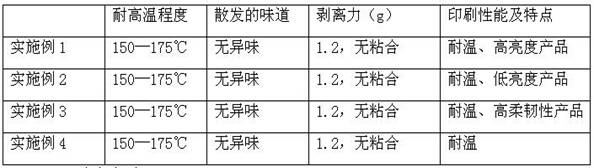

[0037] The present invention will be further described below in conjunction with specific embodiments.

[0038]

[0039]

[0040] The preparation method of high temperature resistant water-based transfer coating in the foregoing embodiment may further comprise the steps:

[0041] (1) Transfer resin synthesis

[0042]A. In the reaction kettle, add acrylic resin, polymer of fumarated rosin, glycerol and pentaerythritol, urea, glyoxal and formaldehyde polymer, ethyl acetate and n-propyl acetate according to the ratio, constant temperature 60°C, 600rp Disperse at a rotating speed for 120 minutes until the solution becomes clear;

[0043] B. Add polysiloxane resin and absolute ethanol, keep the temperature at 60°C, continue to disperse for 60 minutes, and rotate at 1000rpm;

[0044] C. Add ammonia water to neutralize, adjust to PH=8±0.5, add water and stir at 1000rpm until the solution becomes clear, then use 2-hydroxyethylamine and the rest of ammonia water to maintain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com