Essence lotion with effects of removing acnes and acne marks and preparation method of essence lotion

A kind of essence milk and anti-acne technology, which is applied in the field of skin care products and can solve problems such as restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

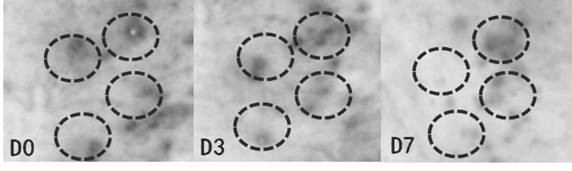

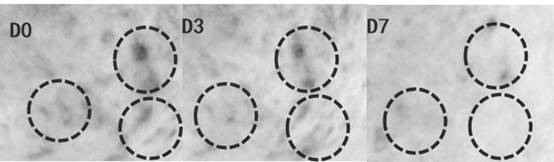

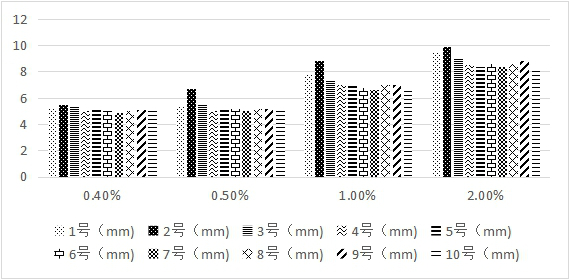

Image

Examples

Embodiment 1

[0063] (1) Weigh 0.1g of sodium alginate, 0.1g of cyclodextrin, 0.1g of hydrogenated lecithin, 0.1g of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer, and 79.4g of water with a stirrer Stir to make a mixed solution.

[0064] (2) Put the above mixed solution in a water bath at a temperature of 90°C for high temperature sterilization for 30 minutes;

[0065] (3) After cooling down to 80°C-85°C, add 20g of Vitex paniculata extract to the sterilized solution and stir evenly to form a milky liquid;

[0066] (5) Homogenize the above emulsion with a homogenizer for 3 minutes, add 0.2 g of sodium hydroxide to obtain a uniform and stable emulsion;

[0067] (6) Spray-dry the above-mentioned emulsion to obtain Suihua microcapsule powder; during spray-drying, the inlet air temperature is controlled at 180°C, the outlet air temperature is controlled at 80°C, and the feed temperature is controlled at 45°C.

Embodiment 2

[0069] (1) Weigh 1g of sodium alginate, 1.5g of cyclodextrin, 0.5g of hydrogenated lecithin, 0.5g of acrylic acid (ester) / C10-30 alkanol acrylate crosspolymer, and 56.375g of water, and stir to prepare into a mixed solution.

[0070] (2) Put the mixed solution obtained in the above step (1) in a water bath at a temperature of 95°C for high-temperature sterilization for 35 minutes;

[0071] (3) Cool down to 80°C-85°C, add 40g Vitex paniculata extract to the above-mentioned sterilized solution, stir evenly, and form a milky liquid;

[0072] (5) Homogenize the above emulsion with a homogenizer for 5 minutes, add 0.125 g of sodium hydroxide to obtain a uniform and stable emulsion;

[0073] (6) Spray-dry the above-mentioned emulsion to obtain Suihua microcapsule powder; during spray-drying, the inlet air temperature is controlled at 160°C, the outlet air temperature is controlled at 100°C, and the feed temperature is controlled at 50°C.

Embodiment 3

[0075] (1) Weigh 1.5g of sodium alginate, 5g of cyclodextrin, 1g of hydrogenated lecithin, 1g of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer, and 41.3g of water, and stir to make a mixed solution.

[0076] (2) Sterilize the mixed solution obtained in the above step (1) in a water bath at a temperature of 85°C for 60 minutes;

[0077] (3) Cool down to 80°C-85°C, add 50g of Vitex paniculata extract to the above-mentioned sterilized solution, stir evenly, and form a milky liquid;

[0078] (4) Homogenize the above emulsion with a homogenizer for 5 minutes, add 0.2 g of sodium hydroxide to obtain a uniform and stable emulsion;

[0079] (5) Spray-dry the above-mentioned emulsion to obtain Suihua microcapsule powder; during spray-drying, the inlet air temperature is controlled at 200°C, the outlet air temperature is controlled at 90°C, and the feed temperature is controlled at 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com