Magnesium phosphate-based foam concrete thermal insulation material

A foam concrete, thermal insulation technology, applied in the field of thermal insulation materials, can solve the problems of limited use conditions, low early strength, uneven pores, etc., and achieve the effects of easy storage, reduced cohesion, and stable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

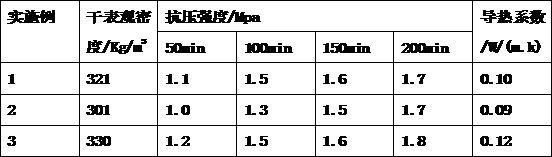

Examples

preparation example Construction

[0077] In still another embodiment of the present invention, the preparation method of the above-mentioned phosphate-based foam concrete thermal insulation material is provided, including the following steps:

[0078] (1) Powder Preparation: Weigh magnesia, active foaming agent, mortal air intake agent, mineral blend, high-efficiency water reducer, composite continuous agent, phosphate, quartz sand water resistant agent, phosphate, quartz sand water resistant, PH Stabilizer, stir well after mixing;

[0079] (2) mixing with water: mix the prepared powder and water in a ratio of 1: 0.1 to 0.2, stirred into a slurry.

[0080] In still another embodiment of the present invention, it is used to provide a phosphate-based foam concrete thermally insulating material in the field of construction project insulation.

[0081] Specifically, the application means is evenly applied to the concrete surface after mixing the phosphate-based foam concrete thermally insulating material and water.

Embodiment 1

[0084] Method for preparing a phosphate-based foam concrete thermally insulating material, including the following steps:

[0085] (1) Production of powder: 80 parts of magnesium according to the above ratio (group distribution ratio of 80 parts of light, 20 parts of magnesium hydroxide), activated foaming agent (group distribution ratio: animal collagen) 50 parts of powder, 15 sodium dodecyl sulfate, 10 methal cellulose, 15 parts of triethanolamine, 10 parts of hydroxyethylcellulose), 200.2 parts of a mortal ventilator (dodecyl benzenesulfonic acid) 20 parts of sodium, 30 parts of the PO type alcoholamine copolymer, 20 succinate, 15 copies of modified oil tea saponins.) 20 parts of mineral blend (group distribution ratio: 50 copies, silicone gray 25 SiO, nano 2 5 copies of the high-efficiency water reduction agent (group distribution ratio: polyether 40 parts, polyacrylate), 15 parts of the composite continuous agent (group dispensing ratio: 50 parts of boron sand, 30 urea, 20 bo...

Embodiment 2

[0088] Method for preparing a phosphate-based foam concrete thermally insulating material, including the following steps:

[0089] (1) Pubic Preparation: According to the above proportion of magnesium concentrates (group distribution ratio: 70 parts of mild magnesium, 30 parts of magnesium hydroxide), and 6 parts of the active blowing agent (group distribution ratio: animal collagen) 50 parts of powder, 15 sodium dodecyl sulfate, 10 methal cellulose, 15 parts of triethanolamine, 10 parts of hydroxyethylcellulose), 200.2 parts of a mortal ventilator (dodecyl benzenesulfonic acid) 20 parts of sodium, 30 parts of the PO type alcoholamine copolymer, 20 succinate, 15 parts of modified oil tea saponins.) 30 parts of mineral blend (group distribution ratio: 60 parts of fly ash, silicon ash 30 SiO, nano 2 5 copies of the high-efficiency water reduction agent (group distribution ratio: polyether 40 parts, polyacrylate), 15 parts of the composite continuous agent (group dispensing ratio: 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com