A kind of palm oil-based underwater adhesive and preparation method thereof

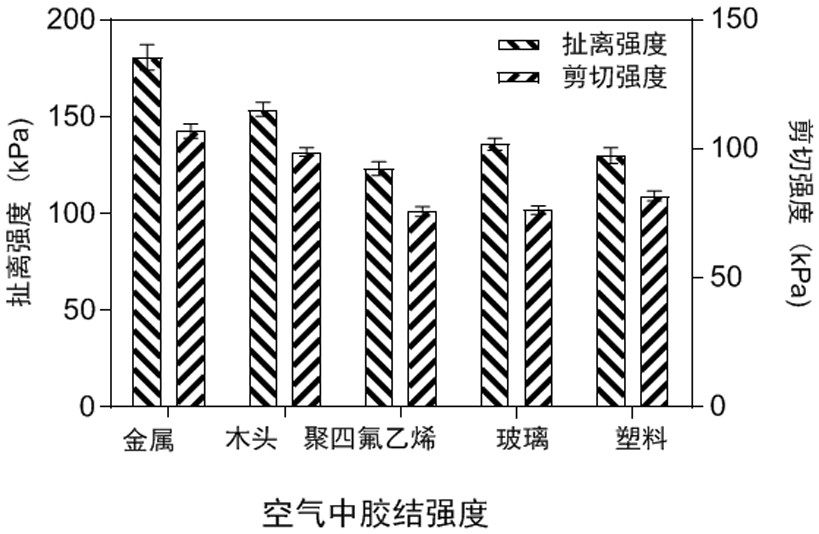

A palm oil and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, amide/imide polymer adhesives, etc., can solve the problem of poor mechanical properties of vegetable oil adhesives, preparation process Complex, poor bonding performance of thermoplastic underwater adhesives, etc., to achieve high bonding strength, low price, and increase water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The synthetic process of palm oil fatty acid acrylamide ethyl ester: put 150g palm oil and 150ml tetrahydrofuran in a three-necked flask; then add 115g N -Hydroxyethyl acrylamide, 0.1g 2,6 dimethylphenol, 5g sodium hydroxide; then, the flask was placed in a water bath and magnetically stirred (rotation speed 150 r / min) and reacted at 40°C for 16h; the reaction products were respectively After repeated purification by saturated brine for 3 to 5 times, and purification by rotary evaporation, palm oil fatty acid acrylamide ethyl ester is obtained.

[0025] The preparation method of the underwater adhesive: 0.01mol (5.2g) of palm oil propylene monomer, 0.04mol (8.3g) of isobornyl acrylate and 0.27g of photoinitiator are mixed uniformly and then poured into a tetrafluoroethylene mold. It was cured by irradiating it with ultraviolet light with a wavelength of 405nm for 15s.

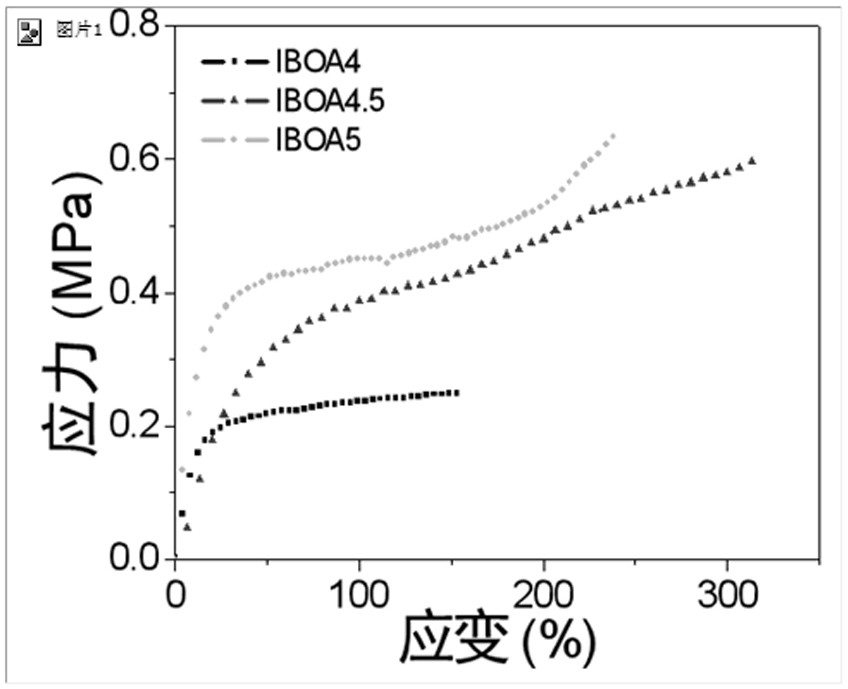

[0026] In the preparation process, the dosage ratio of palm oil propylene monomer and isobornyl acry...

Embodiment 2

[0028] Synthesis process of palm oil fatty acid acrylamide ethyl ester: put 150g palm oil and 150ml tetrahydrofuran in a three-necked flask; then add 115g N -Hydroxyethyl acrylamide, 0.1g 2,6 dimethylphenol, 5g sodium hydroxide; then, the flask was placed in a water bath and magnetically stirred (rotation speed 150 r / min) and reacted at 40°C for 16h; the reaction products were respectively After repeated purification by saturated brine for 3 to 5 times, and purification by rotary evaporation, palm oil fatty acid acrylamide ethyl ester is obtained.

[0029] The preparation method of the underwater adhesive: 0.01mol (5.2g) of palm oil propylene-based monomer, 0.045mol (9.4g) of isobornyl acrylate and 0.4g of photoinitiator are mixed uniformly and then poured into a tetrafluoroethylene mold. It was cured by irradiating it with ultraviolet light with a wavelength of 405nm for 15s.

[0030] In the preparation process, the dosage ratio of palm oil propylene monomer and isobornyl ac...

Embodiment 3

[0032] Synthesis process of palm oil fatty acid acrylamide ethyl ester: put 150g palm oil and 150ml tetrahydrofuran in a three-necked flask; then add 115g N -Hydroxyethyl acrylamide, 0.1g 2,6 dimethylphenol, 5g sodium hydroxide; then, the flask was placed in a water bath and magnetically stirred (rotation speed 150 r / min) and reacted at 40°C for 16h; the reaction products were respectively After repeated purification by saturated brine for 3 to 5 times, and purification by rotary evaporation, palm oil fatty acid acrylamide ethyl ester is obtained.

[0033] The preparation method of the underwater adhesive: 0.01mol (5.2g) palm oil propylene-based monomer, 0.05mol (10.4g) isobornyl acrylate and 0.4g photoinitiator are mixed uniformly and poured into a tetrafluoroethylene mold. It was cured by irradiating it with ultraviolet light with a wavelength of 405nm for 15s.

[0034] In the preparation process, the dosage ratio of palm oil propylene monomer and isobornyl acrylate is 1:5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com