Single-component polyurethane waterproof coating for decoration and preparation method ofsingle-component polyurethane waterproof coating

A polyurethane waterproof, single-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as harm, affecting people's health, and long-term harm, and achieve improved appearance, dry speed, and fast drying speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

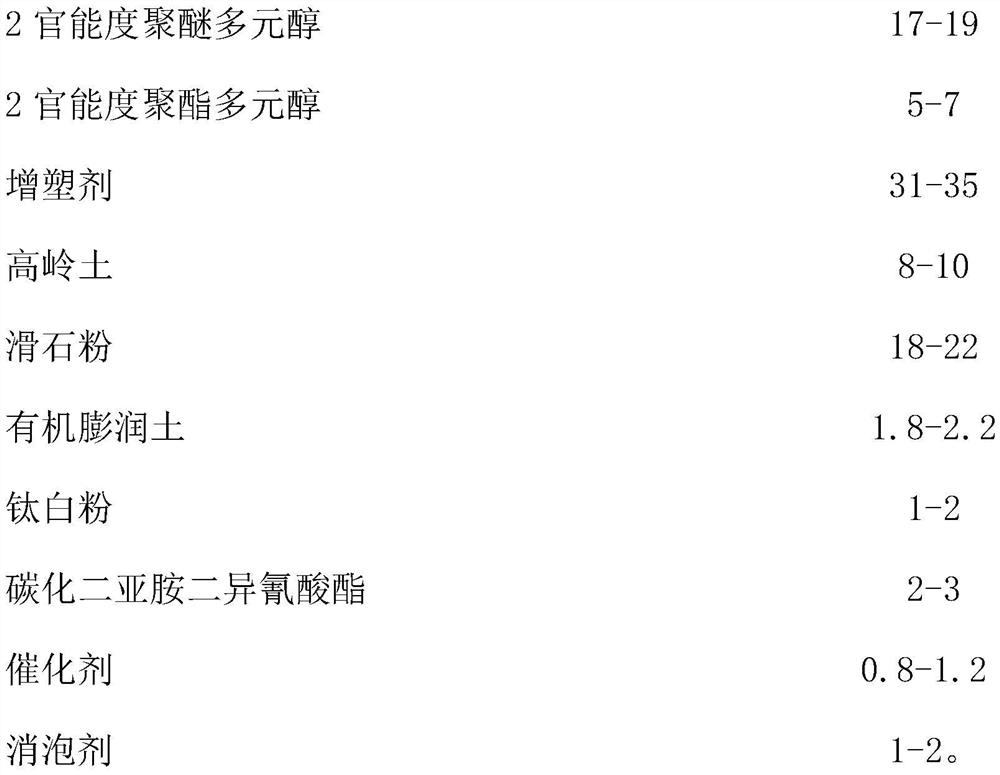

[0022] A one-component polyurethane waterproof coating for decoration, prepared from the following components according to the following parts by mass:

[0023]

[0024] A preparation method for one-component polyurethane waterproof coating for decoration, comprising the steps of:

[0025] Put 2-functionality polyether polyol, 2-functionality polyester polyol, plasticizer, kaolin, talcum powder, organic bentonite and catalyst into the negative pressure reactor, then set the stirring rate to 300r / min, then Drainage at 115°C and pressure of -0.09Mpa for 2 hours;

[0026] Then lower the temperature in the negative pressure reactor to 70°C and turn off the negative pressure, then add carbodiimide diisocyanate, then stir at a constant temperature at 75°C for 1.5h, then add titanium dioxide at 60°C and Stir at constant temperature for 0.5h;

[0027] Finally, add a defoamer at 55°C and keep it warm for 15 minutes, then keep it at a temperature of 45°C and a pressure of -0.095mpa...

Embodiment 2

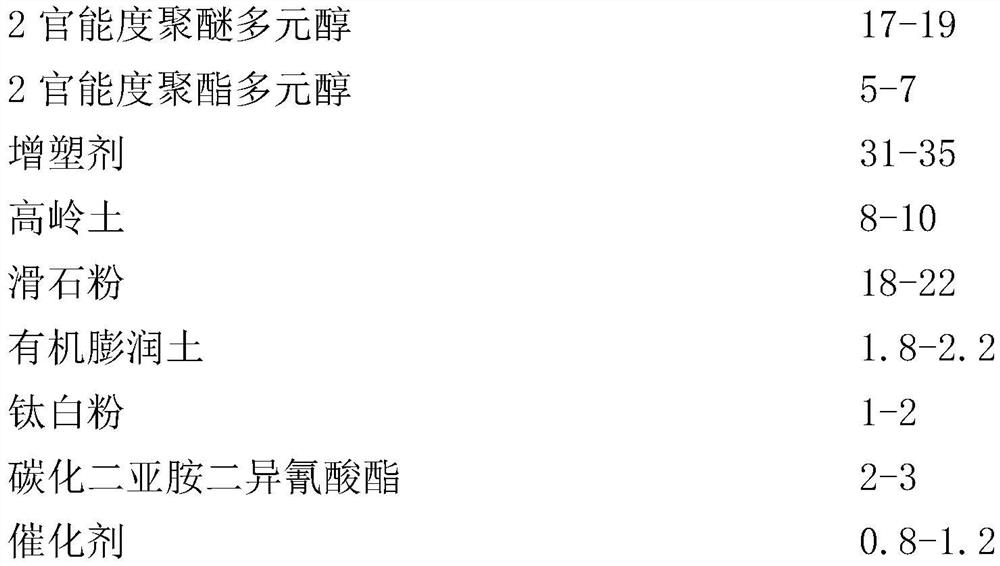

[0029] A one-component polyurethane waterproof coating for decoration, prepared from the following components according to the following parts by mass:

[0030]

[0031]

[0032] A preparation method for one-component polyurethane waterproof coating for decoration, comprising the steps of:

[0033] Put 2-functionality polyether polyol, 2-functionality polyester polyol, plasticizer, kaolin, talcum powder, organic bentonite and catalyst into the negative pressure reactor, then set the stirring rate to 500r / min, then Drainage at 125°C and pressure of -0.1Mpa for 4 hours;

[0034] Then lower the temperature in the negative pressure reactor to 80°C and turn off the negative pressure, then add carbodiimide diisocyanate, then stir at a constant temperature at 85°C for 2.5h, then add titanium dioxide at 70°C and Stir at constant temperature for 1.5h;

[0035] Finally, add a defoamer at 60°C and keep it warm for 25 minutes, then keep it at a temperature of 55°C and a pressure o...

Embodiment 3

[0037] A one-component polyurethane waterproof coating for decoration, prepared from the following components according to the following parts by mass:

[0038]

[0039] A method for preparing a one-component polyurethane waterproof coating for decoration, comprising the steps of: adding 2-functionality polyether polyol, 2-functionality polyester polyol, plasticizer, kaolin, talcum powder, organic bentonite and catalyst Put it into a negative pressure reactor, then set the stirring rate to 300-500r / min, then drain water at a temperature of 115-125°C and a pressure of -0.09--0.1Mpa for 2-4h;

[0040] Then lower the temperature in the negative pressure reactor to 75°C and turn off the negative pressure, then add carbodiimide diisocyanate, then stir at 80°C for 2.0h, then add titanium dioxide at 65°C and Stir at constant temperature for 1.0h;

[0041] Finally, add a defoamer at 58°C and keep it warm for 20 minutes, then keep it at a temperature of 50°C and a pressure of -0.09...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com