Method for preparing semeglutide precursor through high-density fermentation

A technology of high-density fermentation and semaglutide, which is applied in the field of high-density fermentation, can solve the problem that the fermentation expression needs to be improved, and achieves the effects of increasing the bacterial fermentation expression, reducing production costs, and having broad industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

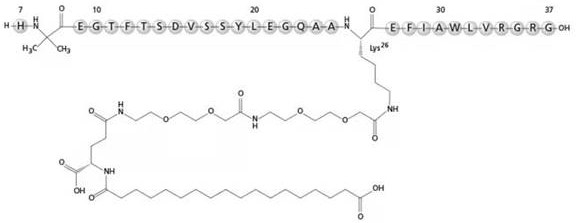

[0053] Example 1: Construction of recombinant Escherichia coli engineering bacteria that stably and highly express semaglutide precursor

[0054] (1) Synthesize the fusion polypeptide encoding genes shown in SEQ ID No.7 and SEQ ID No.8 respectively, and add Nde I enzyme cutting site, 3' end add stop codon and xho I restriction site;

[0055] (2) The gene fragments prepared in step (1) were respectively cloned into the expression vector pET-30a(+) by enzyme digestion. Nde I and xho Between the I enzyme cutting sites, thereby constructing two kinds of recombinant expression vectors pET-30a(+)-A1-GLP-1 and pET-30a(+)-A2-GLP-1;

[0056] (3) Transform the recombinant expression vectors obtained in step (2) into Escherichia coli BL21(DE3) by heat shock method, and select 8 clones after resistance screening, and select 8 clones from the two recombinant engineering bacteria, and name them respectively A1-GLP-1-1 to A1-GLP-1-8 and A2-GLP-1-1 to A2-GLP-1-8 were stored in glycerol....

Embodiment 2

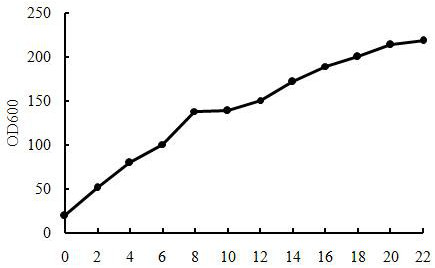

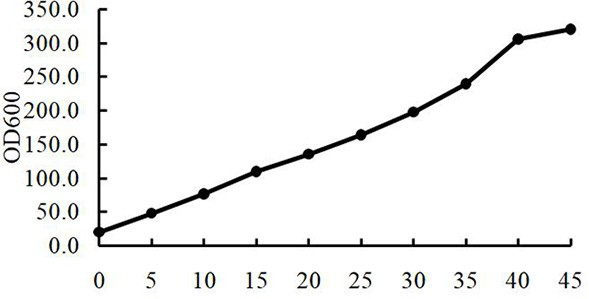

[0058] Embodiment 2: the high-density fermentation (low Mg of recombinant escherichia coli engineering bacterium) 2+ concentration and low OD 600 induced value)

[0059] (1) Solution preparation

[0060] A. Ammonia preparation

[0061] Take 300 ml of purified water in a feeding bottle, and after sterilizing at 121 °C for 30 min, add an equal volume of ammonia water into the feeding bottle under aseptic conditions and mix well for use.

[0062] B. activation medium

[0063] The composition of the activation medium was tryptone 20g / L, yeast extract powder 10g / L, sodium chloride 10g / L; sterilized at 121°C for 30min.

[0064] C. Solution D preparation

[0065] Solution D consists of ferrous sulfate heptahydrate 3.36g / L, zinc sulfate heptahydrate 0.84g / L, manganese sulfate monohydrate 0.51g / L, ammonium molybdate tetrahydrate 0.18g / L, copper sulfate pentahydrate (II) 0.12g / L, phosphoric acid 48ml / L; 0.22μm filter filter sterilization.

[0066] D. feed medium

[0067] 30-...

Embodiment 3

[0079] Embodiment 3: the high-density fermentation of recombinant escherichia coli engineering bacteria

[0080] (1) Solution preparation

[0081] A. Ammonia preparation

[0082] Take 300 ml of purified water in a feeding bottle, and after sterilizing at 121 °C for 30 min, add an equal volume of ammonia water into the feeding bottle under aseptic conditions and mix well for use.

[0083] B. activation medium

[0084] The medium consists of tryptone 20g / L, yeast extract powder 10g / L, sodium chloride 10g / L; sterilized at 121°C for 30 min.

[0085] C. Solution D preparation

[0086] Solution D consists of ferrous sulfate heptahydrate 3.36g / L, zinc sulfate heptahydrate 0.84g / L, manganese sulfate monohydrate 0.51g / L, ammonium molybdate tetrahydrate 0.18g / L, copper sulfate pentahydrate (II) 0.12g / L, phosphoric acid 48ml / L; 0.22μm filter filter sterilization.

[0087] D. feed medium

[0088] 30-50% glucose and 5-25% yeast extract, the specific concentration, supplementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com