Flexible yttrium manganate nanofiber membrane with high infrared reflectivity and preparation method thereof

A nanofiber film and infrared reflection technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve problems such as insufficient infrared shielding performance, poor fiber continuity, and many single fiber defects, and achieve heat resistance. The effect of poor performance, good flexibility, and high infrared reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a flexible high-infrared reflectance yttrium manganate nanofiber membrane, the specific steps are:

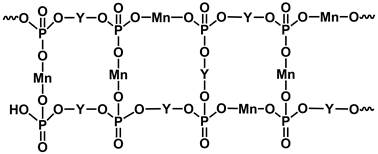

[0046] (1) Dissolve manganese source manganese acetate tetrahydrate, yttrium source yttrium nitrate hexahydrate and heat stabilizer zirconium acetate in solvent water in turn, stir for 30 minutes, then add polyphosphoric acid, heat and stir at 90°C for 60 minutes and mix evenly. The molar ratio of manganese source, yttrium source, heat stabilizer and polyphosphoric acid is 1:1:0.06:0.21, the ratio of the mass sum of manganese source and yttrium source to solvent is 10g:50mL, and the precursor solution has a network The molecular chain of the structure has the following structure:

[0047]

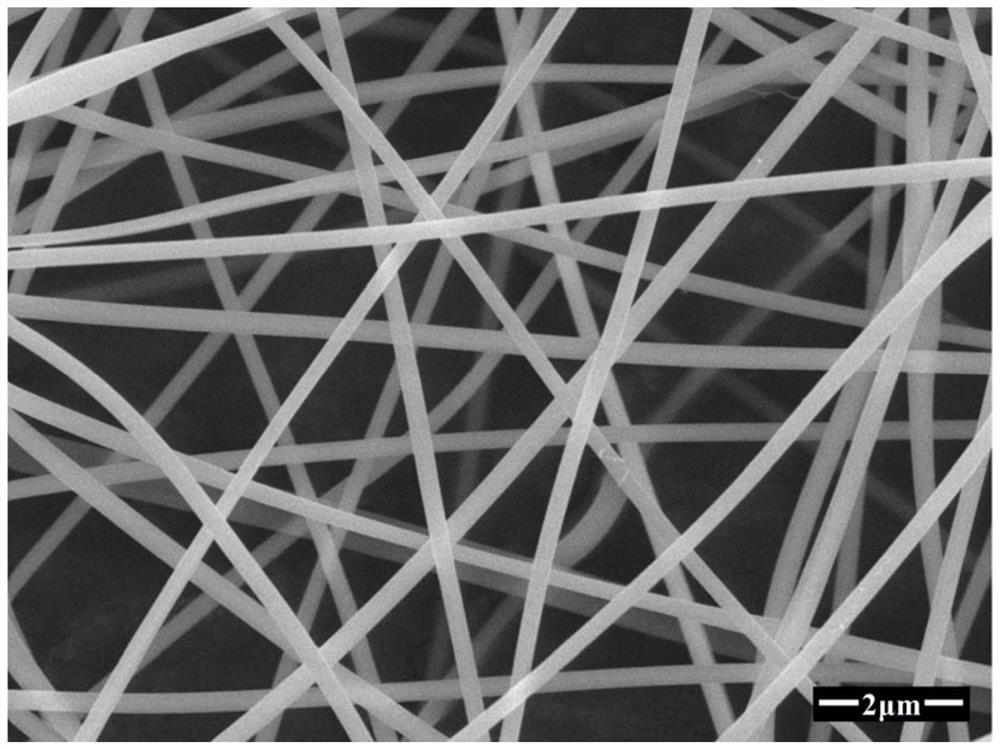

[0048] (2) The above precursor solution was prepared into a precursor fiber film by electrospinning technology. During electrospinning, a heating pack was wrapped outside the syringe. The temperature of the heating pack was 90°C; the process parameters of ele...

Embodiment 2

[0052] A method for preparing a flexible high-infrared reflectance yttrium manganate nanofiber membrane, the specific steps are:

[0053] (1) Dissolve manganese source manganese acetylacetonate, yttrium source yttrium nitrate hexahydrate and heat stabilizer tetrabutyl titanate in the solvent N,N-dimethylformamide in turn, stir for 20min, then add polyphosphoric acid, Heat and stir at 95°C for 80 minutes to mix evenly, wherein the molar ratio of manganese source, yttrium source, heat stabilizer, and polyphosphoric acid in the solution is 1:1:0.03:0.27, and the ratio of the mass sum of manganese source and yttrium source to the mixed solvent 10g:60mL;

[0054] (2) The above precursor solution was prepared into a precursor fiber film by electrospinning technology. During electrospinning, a heating pack was wrapped outside the syringe. The temperature of the heating pack was 85°C; the process parameters of electrospinning were: ambient temperature 30°C ℃, relative humidity 55%, i...

Embodiment 3

[0058] A method for preparing a flexible high-infrared reflectance yttrium manganate nanofiber membrane, the specific steps are:

[0059] (1) Dissolve the manganese source manganese nitrate tetrahydrate, the yttrium source yttrium nitrate hexahydrate and the heat stabilizer ethyl orthosilicate in sequence in the solvent dimethyl sulfoxide, stir for 25 minutes, then add polyphosphoric acid, at 100 ° C Heat and stir for 50min to mix evenly, wherein the molar ratio of manganese source, yttrium source, heat stabilizer and polyphosphoric acid in the solution is 1:1:0.04:0.15, and the ratio of the mass sum of manganese source and yttrium source to the solvent is 10g:70mL ;

[0060] (2) The above precursor solution was prepared into a precursor fiber film by electrospinning technology. During electrospinning, a heating pack was wrapped outside the syringe. The temperature of the heating pack was 80°C; the process parameters of electrospinning were: ambient temperature 24 ℃, relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com