Preparation method of flexible MgAl2O4 nanofiber membrane for chemical warfare agent digestion

A nanofiber membrane, chemical warfare agent technology, applied in heating/cooling fabrics, rayon of inorganic raw materials, textiles and papermaking, etc., can solve the problems of poor fiber continuity, many single fiber defects, and brittle fiber membranes. Achieve the effect of improving catalytic activity, improving viscoelasticity and spinnability, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

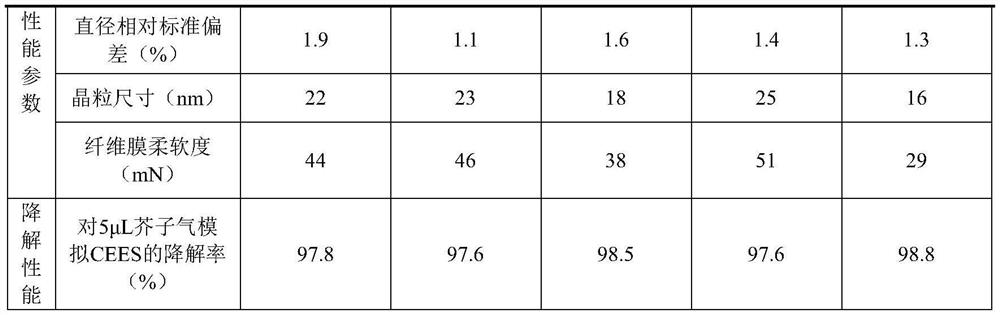

Embodiment 1

[0028] A flexible MgAl for chemical warfare agent digestion 2 o 4 The preparation method of nanofibrous film, concrete steps are:

[0029] (1) Dissolve the magnesium source anhydrous magnesium chloride, the aluminum source anhydrous aluminum chloride and the grain inhibitor tin tetrachloride in solvent water in sequence, first stir for 20 minutes, then add the inorganic gel thickener magnesium lithium silicate, and then Continue to stir for 60 minutes, wherein the molar ratio of magnesium source, aluminum source, grain inhibitor, and inorganic gel thickener in the solution is 1:2:0.04:0.16, and the quality of magnesium source and aluminum source and the ratio to the solvent are 10g : 30mL, mixed evenly to obtain a homogeneous and stable precursor solution with a dynamic viscosity of 8.7Pa·s and an electrical conductivity of 55.6mS / m.

[0030] (2) The above precursor solution is spun into a precursor fiber film by electrospinning technology, and the humidity in the spinning s...

Embodiment 2

[0035] A flexible MgAl for chemical warfare agent digestion 2 o 4 The preparation method of nanofibrous film, concrete steps are:

[0036] (1) Dissolve the magnesium source magnesium ethoxide, the aluminum source anhydrous aluminum chloride and the grain inhibitor methyl orthosilicate in the solvent ethanol in sequence, first stir for 30 minutes, then add the inorganic gel thickener sodium bentonite, and then Continue to stir for 50min, wherein the molar ratio of magnesium source, aluminum source, grain inhibitor and inorganic gel thickener in the solution is 1:2:0.05:0.28, and the ratio of magnesium source, aluminum source and mixed solvent is 10g:42mL , mixed uniformly to obtain a homogeneous and stable precursor solution with a dynamic viscosity of 8.1Pa s and an electrical conductivity of 46.5mS / m;

[0037] (2) The above precursor solution is spun into a precursor fiber film by electrospinning technology, and the humidity in the spinning interval is controlled to be 85% ...

Embodiment 3

[0041] A flexible MgAl for chemical warfare agent digestion 2 o 4 The preparation method of nanofibrous film, concrete steps are:

[0042] (1) Dissolve the magnesium source magnesium sulfate monohydrate, the aluminum source anhydrous aluminum chloride and the grain inhibitor zirconium acetate in the solvent glycerol in sequence, first stir for 35 minutes, then add the inorganic gel thickener diatomaceous earth , and then continue to stir for 75min, wherein the mol ratio of magnesium source, aluminum source, grain inhibitor, inorganic gel thickener in the solution is 1:2:0.06:0.12, the quality of magnesium source, aluminum source and the ratio with solvent 10g:40mL, mixed uniformly to obtain a uniform and stable precursor solution with a dynamic viscosity of 6.8Pa s and an electrical conductivity of 38.9mS / m;

[0043] (2) The above precursor solution is spun into a precursor fiber film by electrospinning technology, and the humidity in the spinning interval is controlled to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com