Matt glaze for sanitary ceramics and preparation method of sanitary ceramics

A technology for sanitary ceramics and matte glaze, applied in the field of sanitary ceramics, can solve the problems of poor thermal stability, narrow firing temperature range, pinholes, etc. The effect of a narrow temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

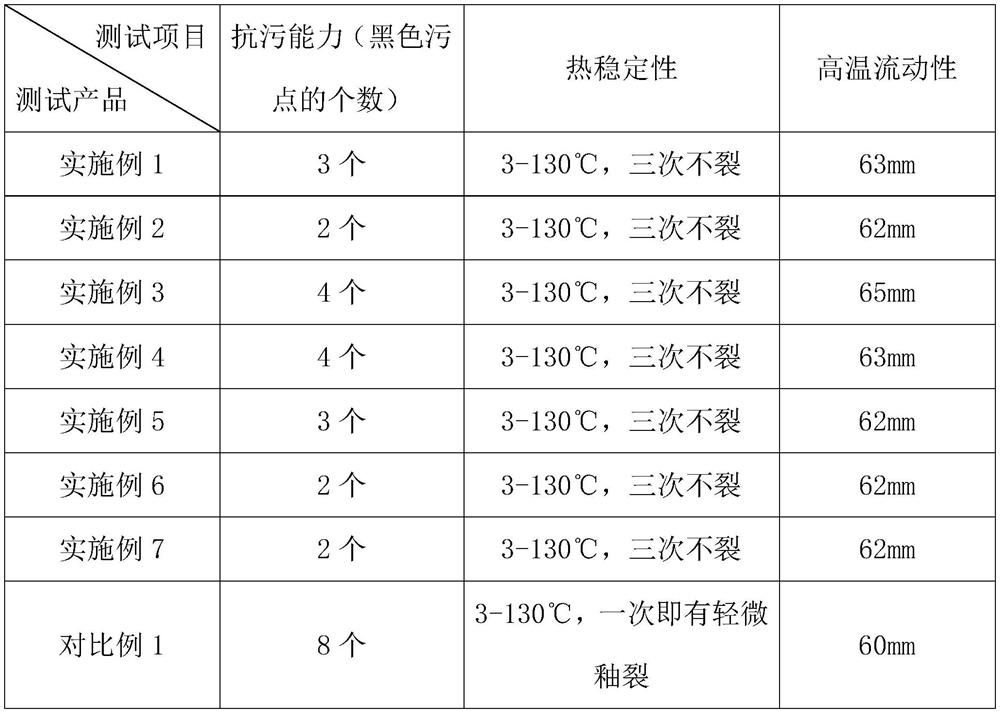

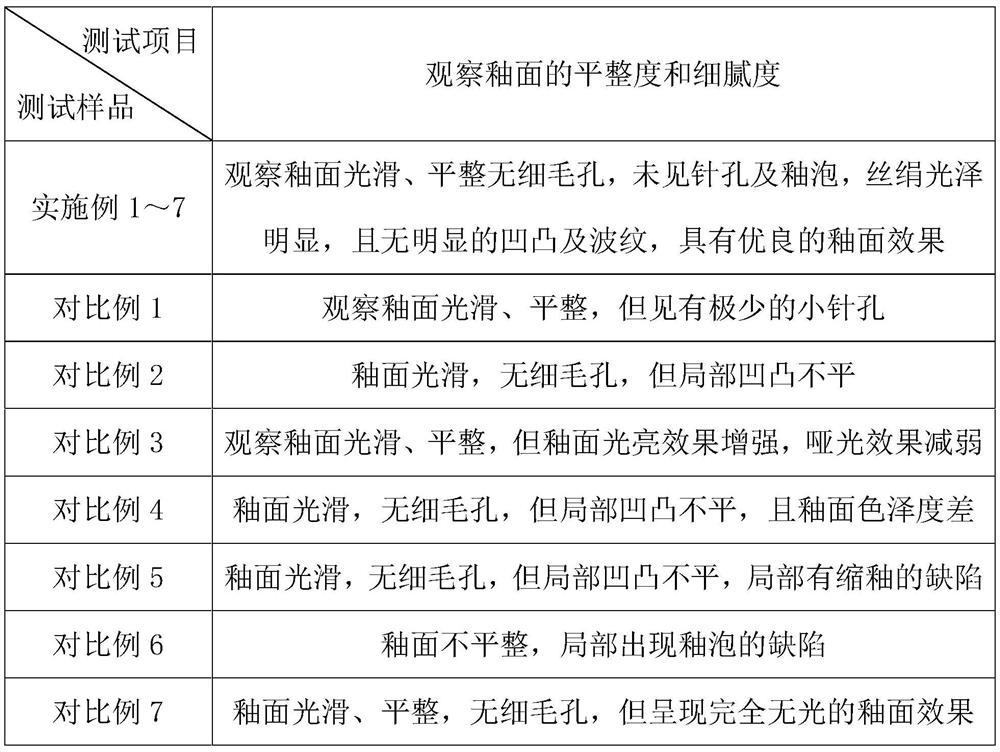

Examples

preparation example Construction

[0048] A preparation method for sanitary ceramics, using the matte glaze for sanitary ceramics, comprising the following steps:

[0049] (1) Green body preparation: add water to the green body raw material to carry out wet ball milling, and make a sanitary ceramic green body by mold grouting;

[0050] (2) Preparation of matte glaze for sanitary ceramics: according to the formula, the raw materials are added to water ball mill, and the glaze slurry after ball milling is subjected to the first iron removal sieving and the second iron removal sieving to obtain matte glaze for sanitary ceramics ;

[0051] (3) Glazing: Spray the matte glaze for sanitary ceramics onto the surface of the sanitary ceramic body by spraying glaze;

[0052] (4) Firing: drying the glazed sanitary ceramic body, and then firing in a kiln to produce a sanitary ceramic.

[0053] By ball milling the basic glaze raw materials and pigments at one time, the ball milling effect can be stabilized, because a large...

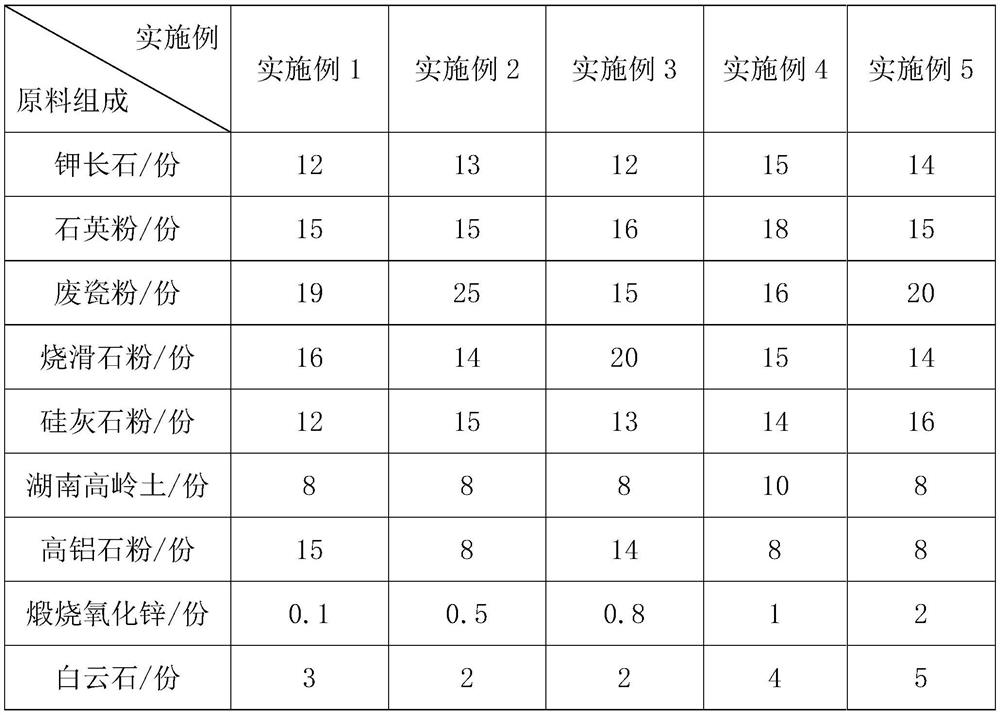

Embodiment 1~5

[0072]A preparation method for sanitary ceramics, comprising the steps of:

[0073] (1) Green body preparation: add water to the green body raw materials (using the existing conventional green body raw material formula) and carry out wet ball milling. In the slurry obtained by ball milling, the mass of raw materials with a particle size of less than 10 μm accounts for 53% of the total mass of green body raw materials , the sanitary ceramic green body is obtained by mold grouting;

[0074] (2) Preparation of matte glaze for sanitary ceramics: according to the formula in Table 1 (calculated according to parts by weight), add water to the raw materials and perform ball milling in a ball mill, wherein, according to the mass ratio of raw materials: balls: water = 1: 2.3: 0.6 Carry out ball milling, the ball milling time is 12h, the fineness of the glaze slurry obtained by ball milling is 400 mesh sieve 3 , to prepare matte glaze for sanitary ceramics;

[0075] (3) Glazing: the mat...

Embodiment 6

[0081] Compared with Example 2, in the preparation of step (2) matt glaze for sanitary ceramics, calculated according to parts by weight, the raw material of the glaze is also added with 2.2 parts of vanadium blue pigment and 1.3 parts of praseodymium yellow material, and the remaining formulas and The preparation method is consistent with that of Example 2, and a sanitary ceramic is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com