Cobalt-free positive electrode material of high-voltage lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and cathode materials, which is applied in the field of cobalt-free cathode materials for high-voltage lithium-ion batteries and its preparation, can solve problems such as deterioration of electrochemical performance, unsatisfactory performance, and obstacles to the industrialization process of cathode materials for lithium-ion batteries. Improved discharge specific capacity, shorter time consumption, and easier realization of the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

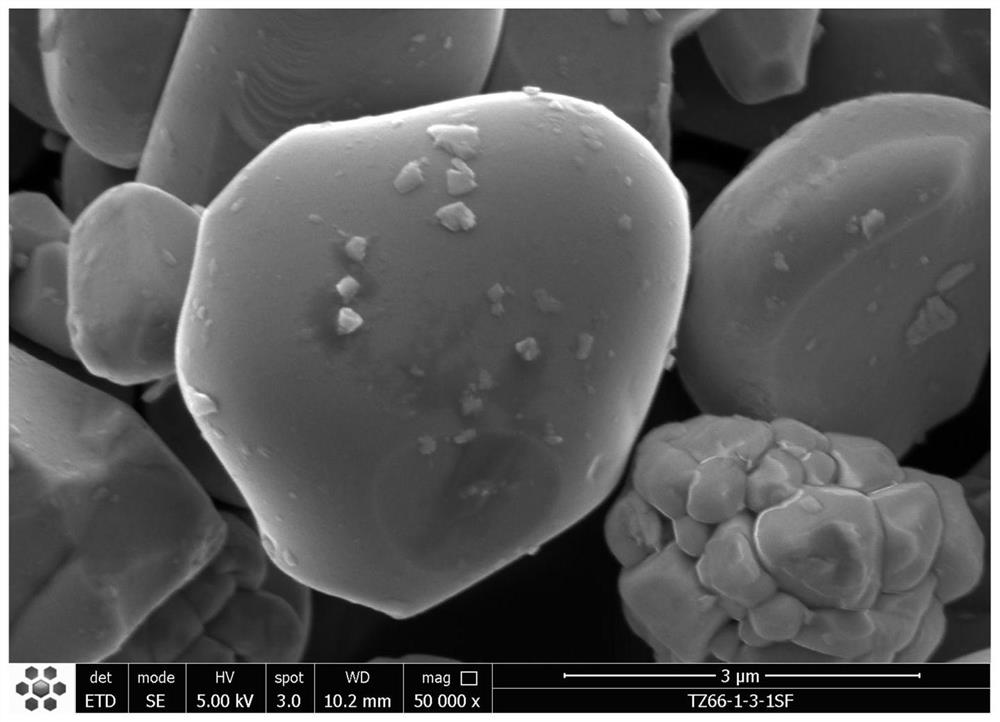

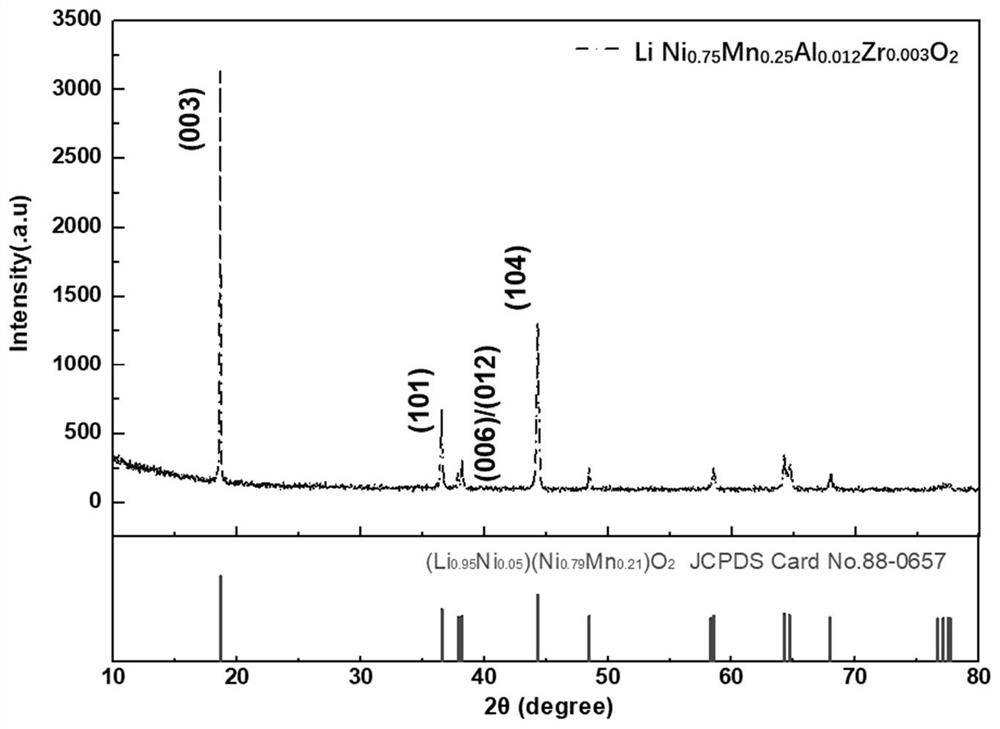

[0039] A kind of high-voltage lithium ion battery cobalt-free cathode material of the present invention is based on single crystal nickel-manganese binary material LiNi 0.75 mn 0.25 al 0.012 o 2 As the matrix, the outer surface of the matrix is coated with a fast ion conductor layer Li 10 GeP 2 S 12 , the weight of the fast ion conductor layer accounts for 1.92wt% of the weight of the matrix, the median particle size D50 of the cobalt-free cathode material for the battery is 5.50 μm, and the compacted density is 3.37 g / cm 3 .

[0040] The preparation method of the high-voltage lithium-ion battery cobalt-free positive electrode material of the present embodiment comprises the following steps:

[0041] (1) Weigh NiSO according to the molar ratio of Ni:Mn=3:1 4 ·6H 2 O, MnSO 4 ·H 2 O is dissolved in deionized water to obtain an aqueous solution with a total metal ion concentration of 2mol / L; the preparation concentration is a 15wt% ammonia solution;

[0042] The prep...

Embodiment 2

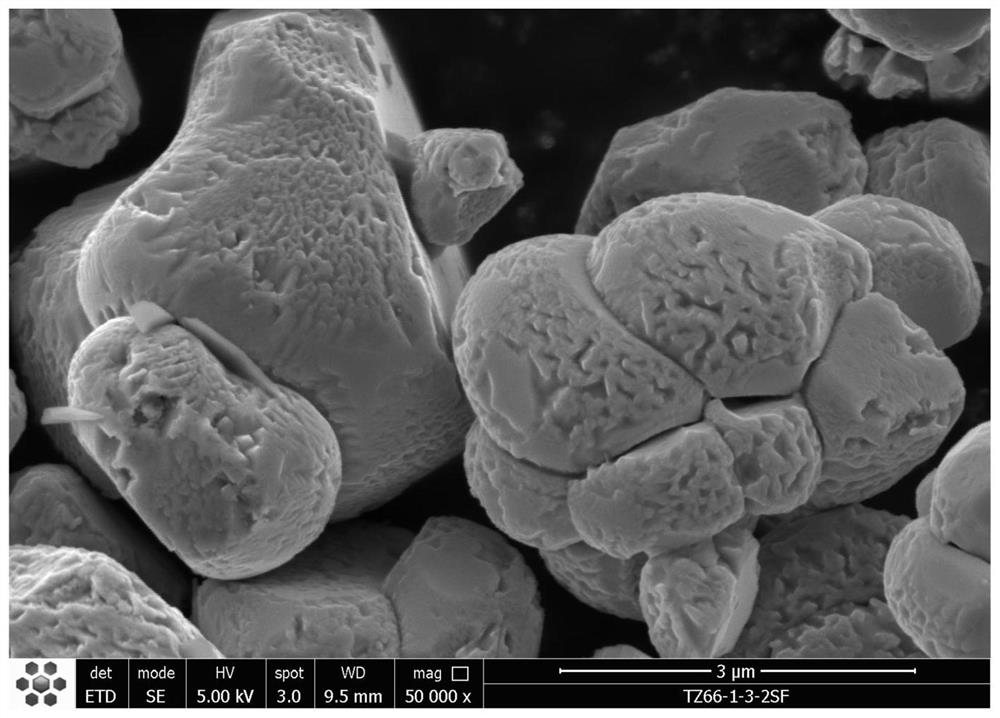

[0055] A kind of high-voltage lithium ion battery cobalt-free cathode material of the present invention is based on single crystal nickel-manganese binary material LiNi 0.75 mn 0.25 Zr 0.003 o 2 As the matrix, the outer surface of the matrix is coated with a fast ion conductor layer LiNbO 3 , the weight of the fast ion conductor layer accounts for 1.46wt% of the weight of the matrix, the median particle size D50 of the cobalt-free cathode material of the battery is 4.92μm, and the compacted density is 3.35g / cm 3 .

[0056] The preparation method of the high-voltage lithium-ion battery cobalt-free positive electrode material of the present embodiment comprises the following steps:

[0057] (1) Weigh NiSO according to the molar ratio of Ni:Mn=3:1 4 ·6H 2 O, MnSO 4 ·H 2 O is dissolved in deionized water to obtain an aqueous solution with a total metal ion concentration of 2mol / L; the preparation concentration is a 15wt% ammonia solution;

[0058] Pump the prepared 2mol...

Embodiment 3

[0066] A kind of high-voltage lithium ion battery cobalt-free cathode material of the present invention is based on single crystal nickel-manganese binary material LiNi 0.75 mn 0.25 Al 0.012 Zr 0.003 o 2 As the matrix, the outer surface of the matrix is coated with a fast ion conductor layer LiTaO 3 , the weight of the fast ion conductor layer accounts for 3.72wt% of the weight of the matrix, the median particle size D50 of the cobalt-free cathode material of the battery is 4.96μm, and the compacted density is 3.32g / cm 3 .

[0067] The preparation method of the high-voltage lithium-ion battery cobalt-free positive electrode material of the present embodiment comprises the following steps:

[0068] (1) Weigh NiSO according to the molar ratio of Ni:Mn=3:1 4 ·6H 2 O, MnSO 4 ·H 2 O is dissolved in deionized water to obtain an aqueous solution with a total metal ion concentration of 2mol / L; the preparation concentration is a 15wt% ammonia solution;

[0069] Pump the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com