Biogas purification double-membrane aeration membrane bio-membrane reactor and use method thereof

A technology of membrane reactor and membrane aeration, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve problems such as insufficient biotransformation, achieve high-efficiency biotransformation, and improve the effect of biotransformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

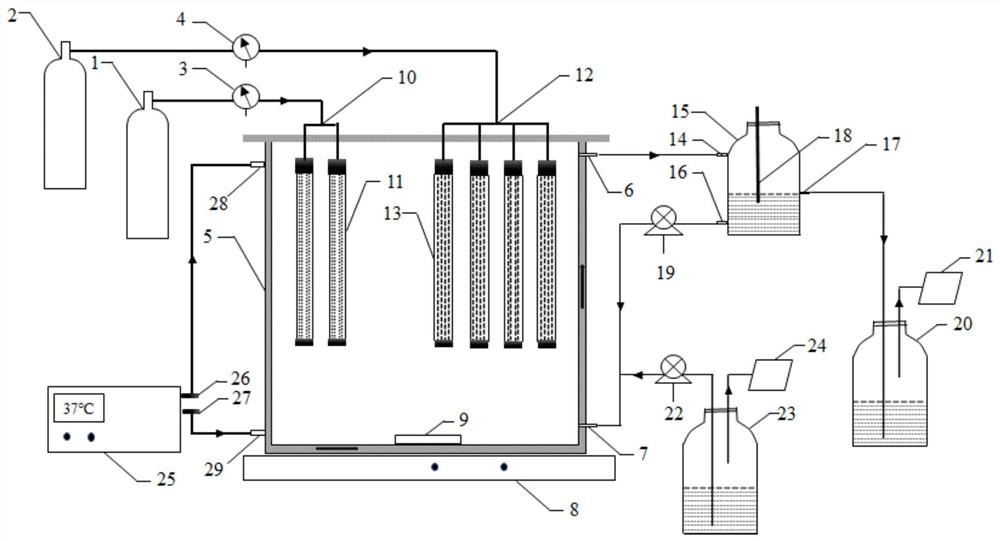

[0019] Specific Embodiment 1: The biogas purification double-membrane aeration membrane biofilm reactor in this embodiment includes a biogas high-pressure cylinder 1, a hydrogen high-pressure cylinder 2, a reactor main body 5, a stirring device, a biogas aeration membrane module 11, a hydrogen aeration Gas membrane module 13, backflow device 15, circulation pump 19, liquid seal device 20, gas collection bag 21, water inlet pump 22, water inlet device 23, water inlet air bag 24 and constant temperature heating device 25; A microbial liquid fermentation medium is provided;

[0020]The reactor main body 5 is provided with a biogas aeration membrane module 11 and a hydrogen aeration membrane module 13, and the gas outlet of the biogas high-pressure cylinder 1 communicates with the biogas aeration membrane module 11 through a pipeline, and the pipeline is equipped with There is a biogas decompression valve 3; the gas outlet of the hydrogen high-pressure cylinder 2 communicates with...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that two biogas aeration membrane modules 11 are arranged in the reactor main body 5, and the biogas aeration membrane modules 11 are composed of hollow fiber membrane tow, The membrane module head and the membrane module fixing part are composed. The membrane module head is arranged at both ends of the hollow fiber membrane tow, and the hollow fiber membrane tow is fixed in the reactor main body 5 through the membrane module fixing part and through the membrane module head. The gas outlet of the biogas high-pressure gas cylinder 1 communicates with the inlet of the two-hole gas distribution valve 10 through the pipeline, and the gas outlet of the two-hole gas distribution valve 10 communicates with the hollow fiber membrane tow through the pipeline.

[0022] Other steps are the same as in the first embodiment.

[0023] The gas mass transfer of the hollow fiber membrane tow in the...

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that four hydrogen aeration membrane modules 13 are arranged in the reactor main body 5, and the hydrogen aeration membrane modules 13 are made of hollow fiber membrane filaments. The membrane module head is set at both ends of the hollow fiber membrane bundle, and the hollow fiber membrane bundle is fixed on the reactor body through the membrane module holder and the membrane module head. 5; the gas outlet of the hydrogen high-pressure cylinder 2 communicates with the air inlet of the four-hole gas distribution valve 12 through the pipeline, and the gas outlet of the four-hole gas distribution valve 12 communicates with the hollow fiber membrane tow through the pipeline .

[0025] Other steps are the same as those in Embodiment 1 or 2.

[0026] The gas mass transfer of the hollow fiber membrane tow in the hydrogen aeration membrane module 13 is relatively fast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com