Preparation method of novel MOF-based hydrogel gas separation membrane

A gas separation membrane and gas separation technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of restricting industrial expansion application, cumbersome synthesis conditions, high purity requirements, etc., to improve separation selectivity, The preparation method is simple and the effect of improving the separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

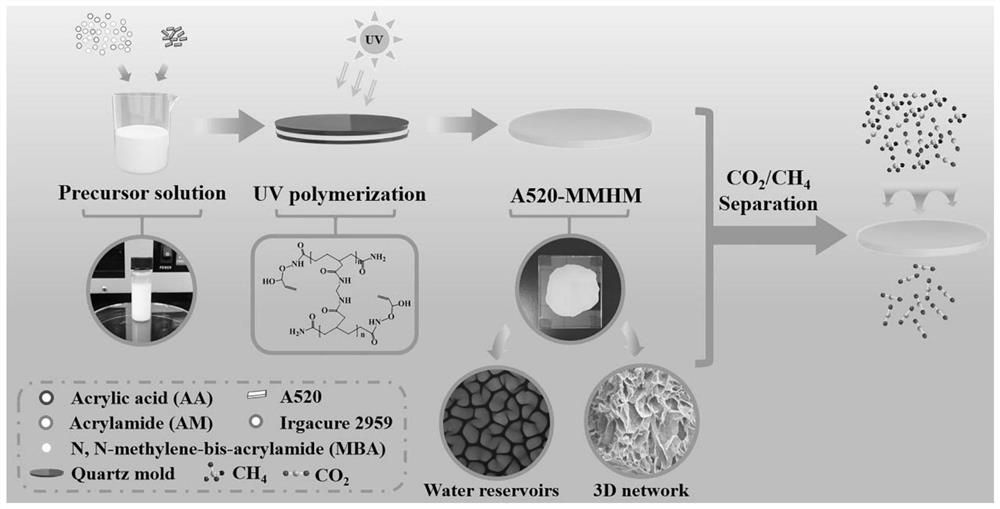

[0039] Example 1-6: Preparation of A520 Hydrogel Gas Separation Membranes with the Same Polymerized Precursor Water Content and Different MOF Contents

[0040] (1) Preparation of A520

[0041] At room temperature, dissolve 7g of aluminum sulfate octadecahydrate in 30mL of water in a glass reactor, and heat the mixed solution to 60°C; weigh fumaric acid (2.43g) and sodium hydroxide (2.52g), dissolve it in 36mL of water and heat up to 60°C After that, slowly add it dropwise to the aqueous solution of aluminum sulfate, the formed white suspension is centrifuged at 9000rpm, washed with water for 3 times, then vacuum-dried at 100°C for 24h to obtain A520 white powder;

[0042] (2) Preparation of polymeric precursor solution

[0043] At room temperature, weigh 2 g of acrylic acid, 1 g of acrylamide, and 0.02 g of N,N'-methylenebisacrylamide and add them to 10 mL of water. After mixing evenly, add 1.11 g of sodium hydroxide to adjust the pH of the solution to neutral, and then add ...

Embodiment 7-11

[0053] Example 7-11: Preparation of A520 Hydrogel Gas Separation Membrane with Same Loading Capacity and Different Water Content of Polymerized Precursors

[0054] (1) The preparation of A520 is the same as step (1) in Example 1;

[0055] (2) Preparation of polymeric precursor solution

[0056] At room temperature, weigh 2 g of acrylic acid, 1 g of acrylamide, and 0.02 g of N,N'-methylenebisacrylamide and add it to a certain amount of water (see the table below for the amount of water), mix well, and then add 1.11 g of sodium hydroxide to adjust the pH of the solution to Neutral, then add 0.3985g A520 (A520 content is 11.6%), 0.015g photoinitiator Irgacure 2959 in the reactor, mix well and set aside;

[0057]

[0058]

[0059] (3) the preparation of film material is with embodiment one step (3)

[0060] Figure 7 : Under dry gas conditions, the CO of A520 hydrogel gas separation membranes with the same A520 content and different polymerization precursor water content ...

Embodiment 12

[0061] Example 12: Preparation and repeated use of A520 hydrogel gas separation membrane with MOF content of 16.24%

[0062] (1) The preparation of A520 is the same as step (1) in Example 1;

[0063] (2) Preparation of polymeric precursor solution

[0064] Among them, A520 content is 16.24%;

[0065] (3) the preparation of film material is with embodiment one step (3)

[0066] Figure 8 is the 6-time reused CO 2 / CH 4 Mixed gas separation performance diagram; because both A520 and hydrogel polymer chains can form hydrogen bonds with water, the membrane still retains CO after 6 cycles 2 The permeation rate of 390Barrer, CO 2 / CH 4 The selectivity is 45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com