Catalyst for preparing maleic anhydride by oxidizing n-butane as well as preparation method and application of catalyst

A catalyst and a technology for n-butane, which are applied in the field of n-butane oxidation to maleic anhydride catalyst and its preparation field, can solve the problems of increasing the complexity of the process, increasing the additional production cost of the catalyst, etc., so as to avoid deep oxidation, improve profits, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Preparation of catalyst precursor:

[0059] 100g V 2 o 5 , 120g 105% phosphoric acid, 26g Bi(NO 3 ) 3 ·5H 2 O is placed in a 3L three-necked flask, then add 1000mL of isobutanol and 500ml of benzyl alcohol, heat the above mixture to reflux temperature, reflux for 18 hours, and then drop to room temperature to obtain a catalyst slurry, which is centrifuged and used for many times. Wash it with isobutanol, then put it into a 100°C oven and dry it for 24 hours, then transfer it to a muffle furnace, and bake it at 180-280°C for 3-10 hours, and mix the calcined catalyst precursor powder with 4% graphite Mixed and pressed into a certain shape to obtain a catalyst precursor.

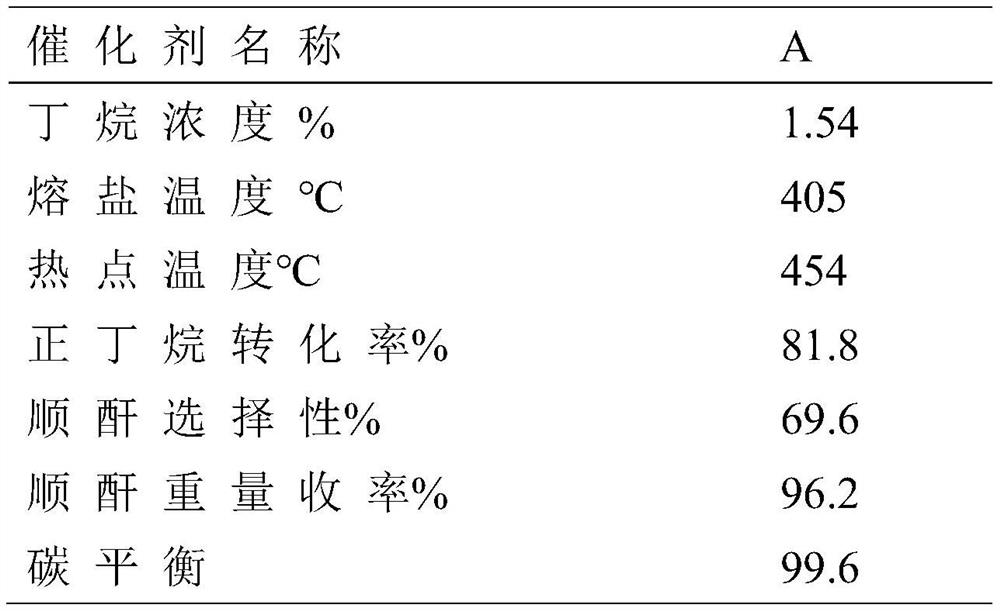

Embodiment 1

[0061] The calcined catalyst powder is mixed with 4% graphite (with a particle size of 6-20 μm), and the mixture is pressed into a clover shape, and placed in an activation furnace for direct activation.

[0062] The first step of activation: the catalyst precursor is raised from room temperature to 430°C, and the heating rate is 4°C / min; is 1.0L / min, and the corresponding airspeed is 800h -1 . The second step of activation: the catalyst was kept at 430°C for 1 hour, then the air was replaced with nitrogen, the flow rate of nitrogen was also 1.0 L / min, and the water vapor remained unchanged, and kept at this temperature for 6 hours.

[0063] Set the specific surface area to 10.0m 2 / g silicon nitride is ground into powder to form particles with a size of 10 μm; the above-mentioned catalyst is also ground into matrix powder with a particle size of about 200-800 mesh, which is fully mixed with the above-mentioned inert carrier particles and pressed into flakes. The content in...

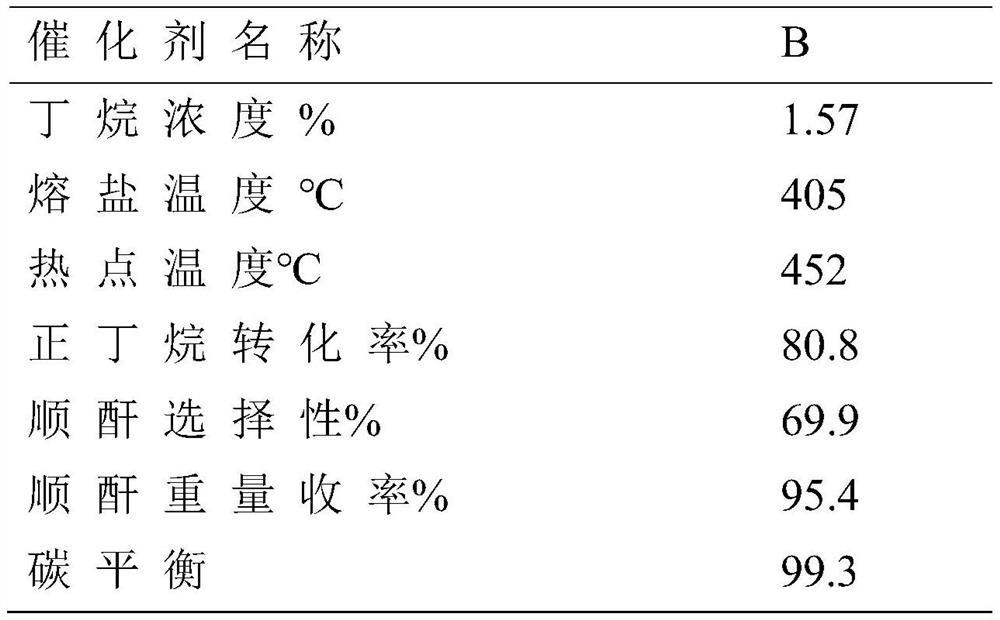

Embodiment 2

[0068] The calcined catalyst powder is mixed with 4% graphite (with a particle size of 6-20 μm), and the mixture is pressed into a clover shape, and placed in an activation furnace for direct activation.

[0069] The first step of activation: the catalyst precursor is raised from room temperature to 430°C, and the heating rate is 4°C / min; is 1.0L / min, and the corresponding airspeed is 800h -1 . The second step of activation: the catalyst was kept at 430°C for 1 hour, then the air was replaced with nitrogen, the flow rate of nitrogen was also 1.0 L / min, and the water vapor remained unchanged, and kept at this temperature for 6 hours.

[0070] Set the specific surface area to 2.0m 2 / g aluminum nitride is ground into powder to form particles with a size of 30 μm; the above-mentioned catalyst is also ground into matrix powder with a particle size of about 200-800 mesh, which is fully mixed with the above-mentioned inert carrier particles and pressed into flakes. Aluminum nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com