Red-mud-based molecular-sieve-oaded titanium dioxide/ferric oxide composite photocatalytic material and preparation method and application thereof

A technology of ferric oxide and composite photocatalysis, applied in molecular sieve catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of high electron and hole recombination efficiency, narrow band gap, etc. , accelerate the oxidation rate, accelerate the effect of catalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

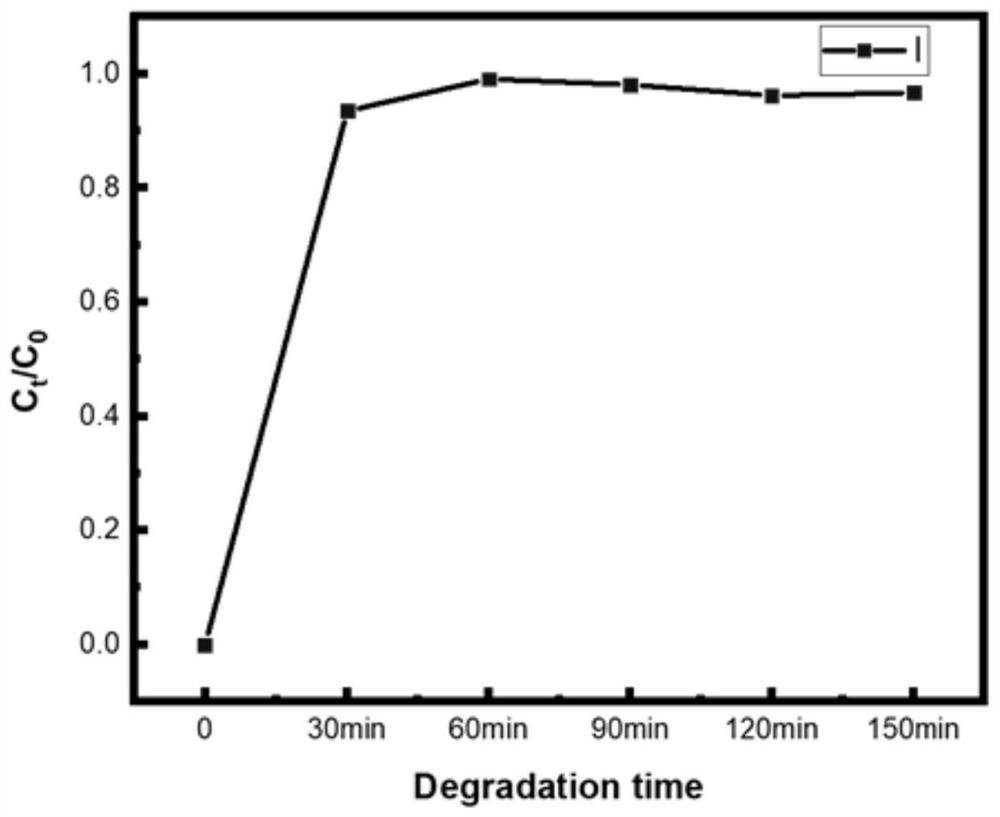

Image

Examples

Embodiment 1

[0039](1) Dry the original untreated red mud in an oven at 60°C for 24 hours, then grind and pass through a 150-mesh sieve to obtain a red mud material with uniform particle size, then wash it with deionized water and alcohol, and then Dry in an oven at 60°C and treat with dilute sulfuric acid with a concentration of 1mol / L. Dissolve every 5g of red mud in 15mL of sulfuric acid, then add 100mL of deionized water for stirring, and dry to obtain acidified red mud material.

[0040] (2) Add 2 g of cetyltrimethylammonium bromide into 100 mL of deionized water, and stir thoroughly for 20 minutes to form solution A.

[0041] (3) Add 4 g of acidified red mud into solution A, and stir for 20 minutes to obtain mixed solution B of red mud and cetyltrimethylammonium bromide.

[0042] (4) Add 8mL, 10mol / L NH 3 ·H 2 O solution, and 10 mL of tetraethyl orthosilicate solution was added thereto, and then fully stirred at 25° C. for 2 hours under the action of a magnetic stirrer to obtain cl...

Embodiment 2

[0052] (1) Dry the original untreated red mud in an oven at 60°C for 24 hours, then grind and pass through a 150-mesh sieve to obtain a red mud material with uniform particle size, then wash it with deionized water and alcohol, and then Dry in an oven at 60°C, and treat with dilute sulfuric acid with a concentration of 2mol / L. Dissolve every 5g of red mud in 15mL of sulfuric acid, then add 100mL of deionized water for stirring, and dry to obtain acidified red mud material.

[0053] (2) Add 3 g of cetyltrimethylammonium bromide into 150 mL of deionized water, and stir thoroughly for 20 minutes to form solution A.

[0054] (3) Add 5 g of acidified red mud into solution A, and stir for 20 minutes to obtain mixed solution B of red mud and cetyltrimethylammonium bromide.

[0055] (4) Add 8mL, 11mol / L NH 3 ·H 2 O solution, and 10 mL of tetraethyl orthosilicate solution was added thereto, and then fully stirred at 25° C. for 2 hours under the action of a magnetic stirrer to obtain ...

Embodiment 3

[0062] (1) Dry the original untreated red mud in an oven at 60°C for 24 hours, then grind and pass through a 150-mesh sieve to obtain a red mud material with uniform particle size, then wash it with deionized water and alcohol, and then Dried in an oven at 60°C, treated with dilute sulfuric acid with a concentration of 3mol / L, dissolved every 5g of red mud in 15mL of sulfuric acid, then added 100mL of deionized water for stirring, and dried to obtain an acidified red mud material.

[0063] (2) Add 4 g of cetyltrimethylammonium bromide into 200 mL of deionized water, and stir thoroughly for 30 minutes to form solution A.

[0064] (3) Add 6 g of acidified red mud into solution A, and stir for 30 minutes to obtain mixed solution B of red mud and cetyltrimethylammonium bromide.

[0065] (4) Add 10mL, 12mol / L NH 3 ·H 2 O solution, and 13 mL of tetraethyl orthosilicate solution was added thereto, and then fully stirred at 25° C. for 2 hours under the action of a magnetic stirrer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com