A kind of collector foaming agent for copper sulfide nickel ore dressing and preparation method thereof

A copper-nickel sulfide ore and foaming agent technology, applied in flotation, solid separation, etc., can solve the problems of cumbersome synthesis process, large material loss, high production cost, etc., achieve simple synthesis process, small material loss, and reduce mineral processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

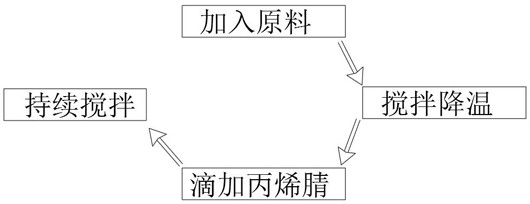

[0026] refer to figure 1 , a collection foaming agent for copper-nickel sulfide ore beneficiation, comprising the following components: carbon disulfide 28.0% wt, diethylamine 36.4% wt, acrylonitrile 24.0% wt, butylamine black medicine 12.6% wt, fusel oil 9.5% % wt, ethanol 5.0% wt, n-butanol 1.0% wt, sodium hydroxide 1.0% wt.

[0027] The present invention also proposes a method for preparing a collecting foaming agent for copper-nickel sulfide beneficiation, comprising the following steps:

[0028] S1: add raw materials, in the reaction vessel, successively add carbon disulfide 28.0% wt, diethylamine 36.4% wt, acrylonitrile 24.0% wt, butylamine black medicine 12.6% wt, fusel oil 9.5% wt, ethanol 5.0% wt, n-Butanol 1.0% wt, sodium hydroxide 1.0% wt;

[0029] S2: stir and cool down, turn on stirring and cool down to 5-15 ℃, then slowly drop acrylonitrile 7.0-10% wt in 30-60min under the condition that the temperature rise does not exceed 35 ℃;

[0030] S3: add acrylonitrile...

Embodiment 2

[0034] refer to figure 1 , a collection foaming agent for copper-nickel sulfide ore beneficiation, comprising the following components: carbon disulfide 30.3% wt, diethylamine 38.6% wt, acrylonitrile 25.7% wt, butylamine black medicine 9.6% wt, fusel oil 6.4% % wt, ethanol 4.0% wt, n-butanol 1.4% wt, sodium hydroxide 2.2% wt.

[0035] The present invention also proposes a method for preparing a collecting foaming agent for copper-nickel sulfide beneficiation, comprising the following steps:

[0036] S1: add raw materials, in the reaction vessel, successively add carbon disulfide 30.3% wt, diethylamine 38.6% wt, acrylonitrile 25.7% wt, butylamine black medicine 9.6% wt, fusel oil 6.4% wt, ethanol 4.0% wt, n-Butanol 1.4% wt, sodium hydroxide 2.2% wt;

[0037] S2: stir and cool down, turn on stirring and cool down to 5-15 ℃, then slowly drop acrylonitrile 7.0-10% wt in 30-60min under the condition that the temperature rise does not exceed 35 ℃;

[0038] S3: add acrylonitrile d...

Embodiment 3

[0042] refer to figure 1 , a collection foaming agent for copper-nickel sulfide ore beneficiation, comprising the following components: carbon disulfide 33.8% wt, diethylamine 41.9% wt, acrylonitrile 28.2% wt, butylamine black medicine 4.9% wt, fusel oil 1.7% % wt% wt, ethanol 3.0% wt, n-butanol 2.0% wt, sodium hydroxide 3.0% wt.

[0043] The present invention also proposes a method for preparing a collecting foaming agent for copper-nickel sulfide beneficiation, comprising the following steps:

[0044] S1: add raw materials, in the reaction vessel, successively add carbon disulfide 33.8% wt, diethylamine 41.9% wt, acrylonitrile 28.2% wt, butylamine black medicine 4.9% wt, fusel oil 1.7% wt% wt, ethanol 3.0% wt, n-butanol 2.0% wt, sodium hydroxide 3.0% wt;

[0045] S2: stir and cool down, turn on stirring and cool down to 5-15 ℃, then slowly drop acrylonitrile 7.0-10% wt in 30-60min under the condition that the temperature rise does not exceed 35 ℃;

[0046] S3: Add acrylon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com