Autoclaved aerated concrete containing coal gangue and iron tailings and preparation method of autoclaved aerated concrete

A technology of autoclaved aeration and coal gangue, applied in the field of building wall materials, can solve the problems of polluting the environment, low comprehensive utilization rate, etc., and achieve the effects of reducing environmental pollution, improving recycling rate, and strong volcanic ash activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

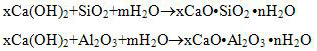

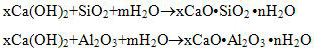

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of autoclaved aerated concrete containing coal gangue and iron tailings, comprising the following steps:

[0043] Step 1, pulverizing the coal gangue to a particle size smaller than 2 mm. The powder is then dried and further ground using a ball mill to a specific surface area of 350-400 m 2 kg -1 of fine powder. Finally, the coal gangue samples were placed in a CD-1400X muffle furnace for vacuum calcination at five calcination temperatures, 500°C, 600°C, 700°C, 800°C, and 900°C for 1-2 hours, and then quenched in water. And the iron ore tailings are dried, and then crushed with a ball mill to obtain a specific surface area of 320-350m 2 kg -1 of fine powder.

[0044] Step 2. Mix the ground iron tailings, aluminum slag and coal gangue with water, add waste materials during the stirring process, control the dispersion of the slurry at 40-45mm, the specific gravity at 1.77-1.85, and the temperature at 35-40°C, stir The speed is 120~140r / min, ...

Embodiment 1

[0051] An iron tailings and coal gangue autoclaved aerated concrete, wherein dry materials: 20 parts of coal gangue, 17 parts of aluminum slag, 35 parts of iron tailings, 5 parts of cement, 10 parts of quicklime, and 5 parts of nano-scale silicon dioxide , 5 parts of metakaolin, 3 parts of waste materials; auxiliary materials: 0.16 parts of aluminum powder, 0.08 parts of foam stabilizer, 0.08 parts of polycarboxylate superplasticizer.

[0052] The preparation method of the above-mentioned iron tailings and coal gangue autoclaved aerated concrete block comprises the following steps:

[0053] Step 1, pulverizing the coal gangue to a particle size smaller than 2 mm. The powder was then dried and further ground using a ball mill to a specific surface area of 350 m 2 kg -1 of fine powder. Finally, the coal gangue samples were placed in a CD-1400X muffle furnace for vacuum calcination at five calcination temperatures, 500°C, 600°C, 700°C, 800°C, and 900°C, and then quenched in ...

Embodiment 2

[0060] An iron tailings and coal gangue autoclaved aerated concrete, wherein dry materials: 20 parts of coal gangue, 15 parts of aluminum slag, 30 parts of iron tailings, 4 parts of cement, 12 parts of quicklime, and 6 parts of nano-scale silicon dioxide , 8 parts of metakaolin, 5 parts of waste materials; auxiliary materials: 0.16 parts of aluminum powder, 0.08 parts of foaming agent, 0.09 parts of polycarboxylate superplasticizer.

[0061] The preparation method of the iron tailings autoclaved aerated concrete block is the same as that of Example 1.

[0062] With reference to GB / T11969-2020 "Autoclaved Aerated Concrete Performance Test Method" and GB / T10294-2008 "Determination of Steady-state Thermal Resistance and Related Properties of Thermal Insulation Materials with Protective Hot Plate Method" to test the performance of the autoclaved aerated concrete obtained in Example 2 Dry density is 520 kg / m 3 , the compressive strength is 4.6MPa, the drying shrinkage value is 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com