High-weather-resistance high-performance modified polyether resin for building exterior wall and sealant

A technology for building exterior walls and polyether resins, applied in the field of silane-modified polyethers, can solve the problems of insufficient weather resistance, inability to meet long-term effective exterior wall waterproofing, etc., and achieves improved heat resistance, high elongation, and improved tensile strength. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A modified polyether resin for building exterior walls with high weather resistance and high performance, prepared by the following preparation method, the preparation steps of the preparation method comprising:

[0047] S1: Put 1000g of polyether polyol PREMINOL S 4318F into the reactor, raise the temperature to 110°C, stir, vacuum dehydrate and degas for 3 hours, cool down to 85°C, then add tetramethylxylylene diisocyanate (TMXDI), Next, add 2g of bismuth carboxylate, stir and mix for 30 minutes at a reaction temperature of 85°C, then raise the temperature to 112°C, and react for 4 hours to obtain a polyurethane prepolymer; among them, polyether polyol PREMINOL S 4318F and tetramethyl The mol ratio of xylylene diisocyanate is 1:2.05;

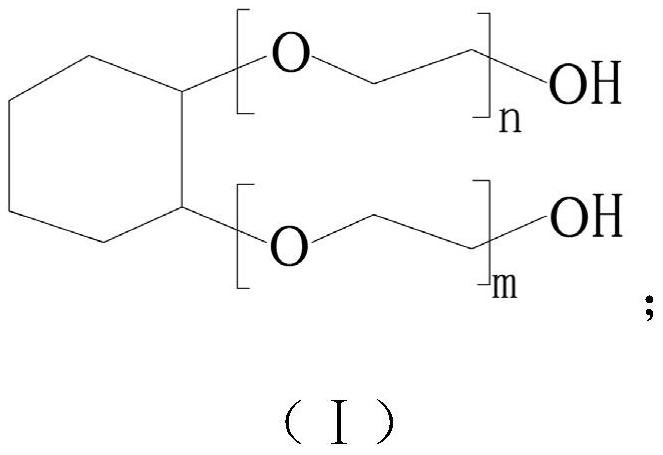

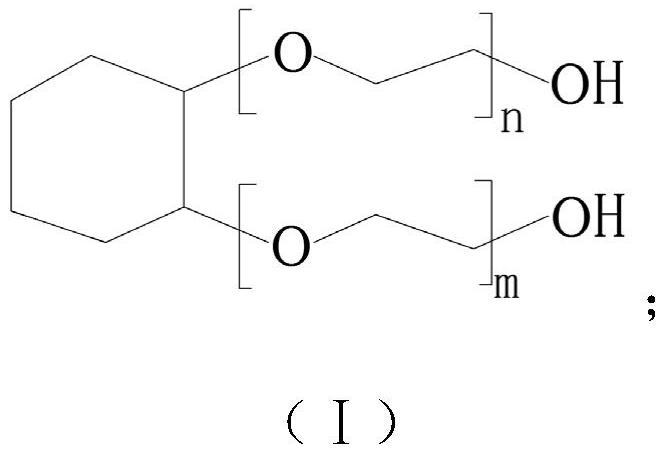

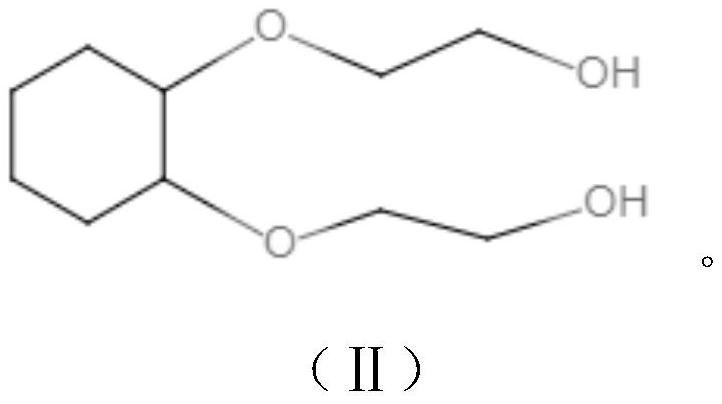

[0048] S2: Add the alkoxylated o-cyclohexanediol to the polyurethane prepolymer obtained above under stirring, and stir and mix the reaction for 4 hours at 115°C to obtain the chain-extended polyurethane prepolymer; wherein, the alkoxyl...

Embodiment 2

[0051] A modified polyether resin for building exterior walls with high weather resistance and high performance, prepared by the following preparation method, the preparation steps of the preparation method comprising:

[0052] S1: Put 1000g of polyether polyol PREMINOL S 4318F into the reactor, raise the temperature to 110°C, stir, vacuum dehydrate and degas for 3 hours, cool down to 85°C, then add tetramethylxylylene diisocyanate (TMXDI), At a reaction temperature of 85°C, stir and mix for 30 minutes, then add 3g of bismuth carboxylate, raise the temperature to 112°C, and react for 4 hours to obtain a polyurethane prepolymer; among them, polyether polyol PREMINOL S 4318F and tetramethylbenzene The molar ratio of dimethyl diisocyanate is 1:2.1;

[0053] S2: Add the alkoxylated o-cyclohexanediol to the polyurethane prepolymer obtained above under stirring, and stir and mix it at 110°C for 4 hours to obtain the chain-extended polyurethane prepolymer; The molar ratio of oxidize...

Embodiment 3

[0056] A modified polyether resin for building exterior walls with high weather resistance and high performance, prepared by the following preparation method, the preparation steps of the preparation method comprising:

[0057] S1: Put 1000g of polyether polyol PREMINOL S 4318F into the reaction kettle, raise the temperature to 110°C, stir, vacuum dehydrate and degas for 3 hours, cool down to 85°C, then add isophorone diisocyanate (IPDI), and then add 3g Dibutyltin dilaurate, stirred and mixed for 30 minutes at a reaction temperature of 85°C, then raised the temperature to 112°C, and reacted for 4 hours to obtain a polyurethane prepolymer; among them, polyether polyol PREMINOL S 4318F and tetramethyl The mol ratio of phenyl dimethyl diisocyanate is 1:2.2;

[0058] S2: When the polyurethane prepolymer obtained above is stirred, the alkoxylated o-cyclohexanediol is added, and the alkoxylated o-cyclohexanediol is stirred and mixed for 4 hours at 110°C to obtain the chain-extended...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com