Titanium dioxide nanowire reinforced corrosion-resistant ceramic coating and preparation method thereof

A technology of titanium dioxide and ceramic coating, which is applied in the field of cermet coating, can solve problems such as insufficient corrosion resistance, and achieve the effects of low cost, improved corrosion resistance, and good hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the preparation method of the titanium dioxide nanowire reinforced corrosion-resistant ceramic coating is as follows:

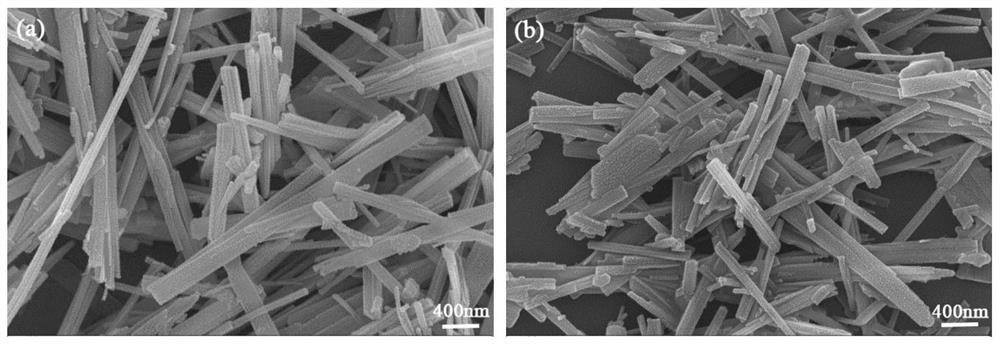

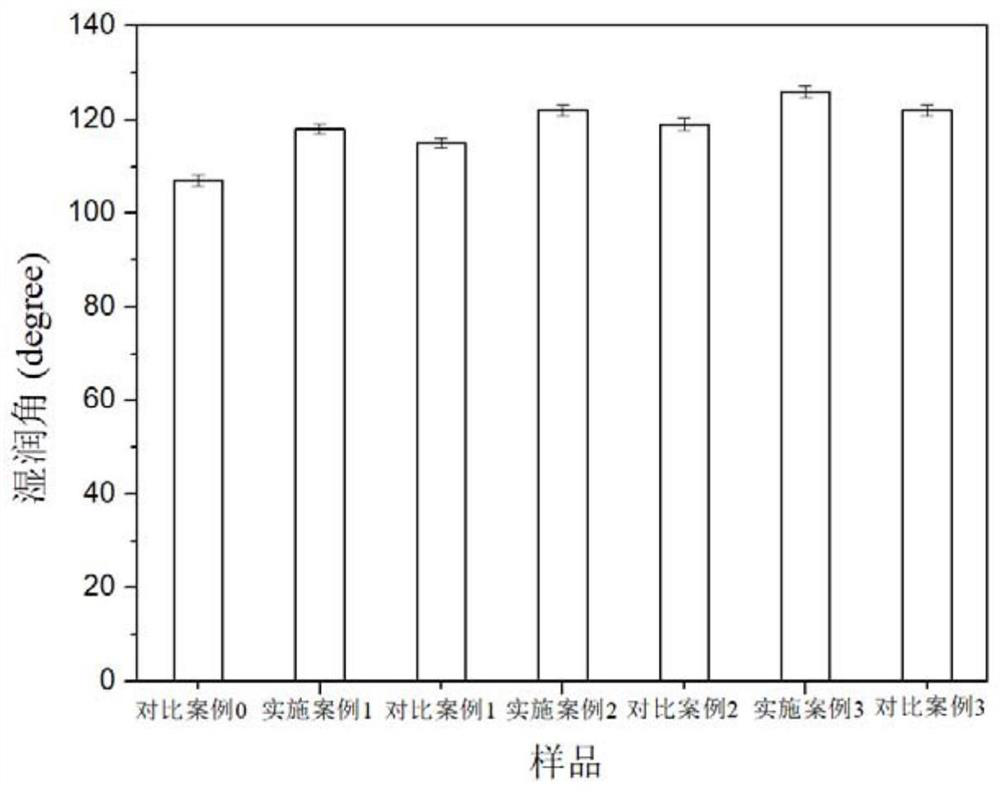

[0033] (1) Prepare 60 mL of sodium hydroxide solution (10M) by magnetic stirring, then add 2 g of titanium dioxide nanoparticles (25 nm) to the sodium hydroxide solution, and stir magnetically until uniform dispersion. Move the solution to a polytetrafluoroethylene reactor and heat it at 180°C for 48 hours; wash the precipitate twice with deionized water; wash the nanowires with 0.5% (v / v) HCl solution until the pH of the cleaning solutionfigure 1 (a) shown.

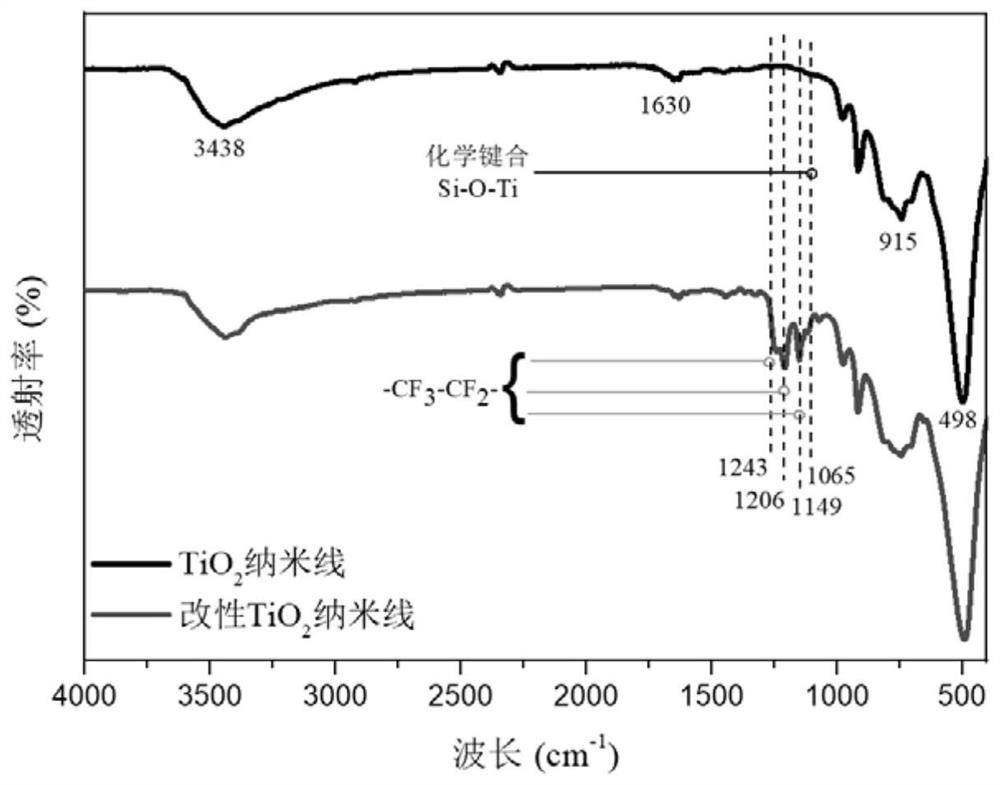

[0034] (2) Add 2 g of heptadecafluorodecyltrimethoxysilane to 30 mL of absolute ethanol and mix well, stir for 2 hours to fully hydrolyze the fluoroalkylsilane; add 6 g of titanium dioxide nanowires to the mixed solution, mix The solution was stirred at 45° C. for 2 hours, and the obtained product was washed three times with absolute ethanol; finally, the modified titanium dio...

Embodiment 2

[0042] In this embodiment, the preparation method of the titanium dioxide nanowire reinforced corrosion-resistant ceramic coating is as follows:

[0043] (1) Prepare 60 mL of sodium hydroxide solution (10M) by magnetic stirring, then add 2 g of titanium dioxide nanoparticles (25 nm) to the sodium hydroxide solution, and stir magnetically until uniform dispersion. Move the solution to a polytetrafluoroethylene reactor and heat it at 180°C for 48 hours; wash the precipitate twice with deionized water; wash the nanowires with 0.5% (v / v) HCl solution until the pH of the cleaning solutionfigure 1 (a) shown.

[0044] (2) Add 2 g of heptadecafluorodecyltrimethoxysilane to 30 mL of absolute ethanol and mix well, stir for 2 hours to fully hydrolyze the fluoroalkylsilane; add 6 g of titanium dioxide nanowires to the mixed solution, mix The solution was stirred at 45° C. for 2 hours, and the obtained product was washed three times with absolute ethanol; finally, the modified titanium dio...

Embodiment 3

[0052] In this embodiment, the preparation method of the titanium dioxide nanowire reinforced corrosion-resistant ceramic coating is as follows:

[0053] (1) Prepare 60 mL of sodium hydroxide solution (10 M) by magnetic stirring, then add 2 g of titanium dioxide nanoparticles (25 nm) into the sodium hydroxide solution, and stir until uniformly dispersed. Move the solution to a polytetrafluoroethylene reactor and heat it at 180°C for 48 hours; wash the precipitate twice with deionized water; wash the nanowires with 0.5% (v / v) HCl solution until the pH of the cleaning solutionfigure 1 (a) shown.

[0054] (2) Add 2 g of heptadecafluorodecyltrimethoxysilane to 30 mL of absolute ethanol and mix well, stir for 2 hours to fully hydrolyze the fluoroalkylsilane; add 6 g of titanium dioxide nanowires to the mixed solution, mix The solution was stirred at 45° C. for 2 hours, and the obtained product was washed three times with absolute ethanol; finally, the modified titanium dioxide nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com