Self-cleaning powder coating for household appliances and furniture and preparation method of self-cleaning powder coating

A powder coating and self-cleaning technology, applied in powder coatings, polyether coatings, anti-corrosion coatings, etc., can solve problems such as poor coordination between nanomaterials and substrates, easy orange peeling of coatings, affecting aesthetics and antifouling effects, etc. Achieve the effect of good compatibility, not easy to produce orange peel, and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

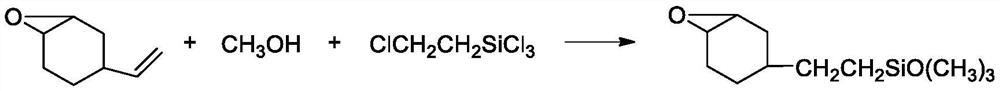

Image

Examples

Embodiment 1

[0032] Prepare modified resin, comprises the steps:

[0033] Step S1: The solution is prepared by adding 70 mL of acetonitrile and 40 mL of dimethyl ether to 200 mL of sodium hypochlorite solution with a mass fraction of 18%, stirring and mixing to obtain an aprotic solution; Hexafluoropropylene oxide was slowly added to 300mL of the solution, and after the addition, the temperature was lowered to -60°C, and 2.5% alkali metal fluorotitanate was added as a catalyst. After 72 hours of magnetic stirring, the temperature was raised to normal temperature, and the reaction liquid was distilled and separated. The intermediate product 1 is obtained; the alkali metal fluorotitanate is sodium fluorotitanate;

[0034]Step S2: Mix 20mL of intermediate product 1 with 350mL of methanol solution with a mass fraction of 70%, and react to generate intermediate product 2 under the action of T-63MP solid acid catalyst resin; dissolve 18mL of intermediate product 2 in 100mL of THF, and add 1.5g ...

Embodiment 2

[0037] Prepare modified resin, comprises the steps:

[0038] Step S1: The solution is prepared by adding 70 mL of acetonitrile and 40 mL of dimethyl ether to 200 mL of sodium hypochlorite solution with a mass fraction of 18%, stirring and mixing to obtain an aprotic solution; Slowly add hexafluoropropylene oxide into 300mL of dissolving solution, after the addition, lower the temperature to -55°C, add 3.5g of alkali metal fluorotitanate as a catalyst, stir the reaction with magnetic force for 80 hours, then raise it to normal temperature, and distill and separate the reaction solution , to obtain the intermediate product 1; the alkali metal fluorotitanate is sodium fluorotitanate;

[0039] Step S2: Mix 20mL of intermediate product 1 with 350mL of methanol solution with a mass fraction of 70%, and react to generate intermediate product 2 under the action of T-63MP solid acid catalyst resin; dissolve 18mL of intermediate product 2 in 100mL of THF, and add 2.5g Sodium borohydrid...

Embodiment 3

[0042] Prepare modified resin, comprises the steps:

[0043] Step S1: The solution is prepared by adding 70 mL of acetonitrile and 40 mL of dimethyl ether to 200 mL of sodium hypochlorite solution with a mass fraction of 18%, stirring and mixing to obtain an aprotic solution; Slowly add hexafluoropropylene oxide into 300mL of dissolving solution, after adding, lower the temperature to -50°C, add 4.5g of alkali metal fluorotitanate as catalyst, react with magnetic stirring for 90h, then raise to normal temperature, and distill and separate the reaction solution , to obtain the intermediate product 1; the alkali metal fluorotitanate is sodium fluorotitanate;

[0044] Step S2: Mix 20mL of intermediate product 1 with 350mL of methanol solution with a mass fraction of 70%, and react to generate intermediate product 2 under the action of T-63MP solid acid catalyst resin; dissolve 18mL of intermediate product 2 in 100mL of THF, and add 3.5g Sodium borohydride was used as a catalyst,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com