Copper-based interlayer alloy and preparation method thereof, and composite connecting piece of ceramic and oxygen-free copper and welding method thereof

A welding method and intermediate layer technology, applied in the field of materials, can solve the problem of high brazing cost and achieve the effects of improving oxidation resistance, firm sealing and good wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned copper-based interlayer alloy provided in the embodiment of the present invention includes:

[0039] According to the target chemical component content, Ti, Sn, Ni, Ag, B, Al, La and Cu are mixed and smelted to form an alloy material.

[0040] specifically:

[0041] 1. If it is prepared as powdery material, its preparation method is:

[0042] Ti, Sn, Ni, Ag, B, Al, La and Cu are mixed and then vacuum smelted, gas atomized and ultrasonically sieved to obtain a powder material with a particle size of 200-800 mesh.

[0043] 2. If it is prepared as a strip material, its preparation method is:

[0044] Mix Ti, Sn, Ni, Ag, B, Al, La and Cu to make alloy ingot by vacuum melting;

[0045] The alloy ingot is made into a strip material through a rapid quenching process.

[0046] Preferably, the strip-shaped material has a thickness of 60 μm-150 μm and a width of 10-110 mm.

[0047] The embodiment of the present invention provides a...

Embodiment 1

[0052] A copper-based intermediate layer material is composed of the following components in weight percentage: 23% Ti, 10% Sn, 3.5% Ni, 0.8% Ag, 0.2% B, 0.3% Al, 0.1% La and the balance of copper.

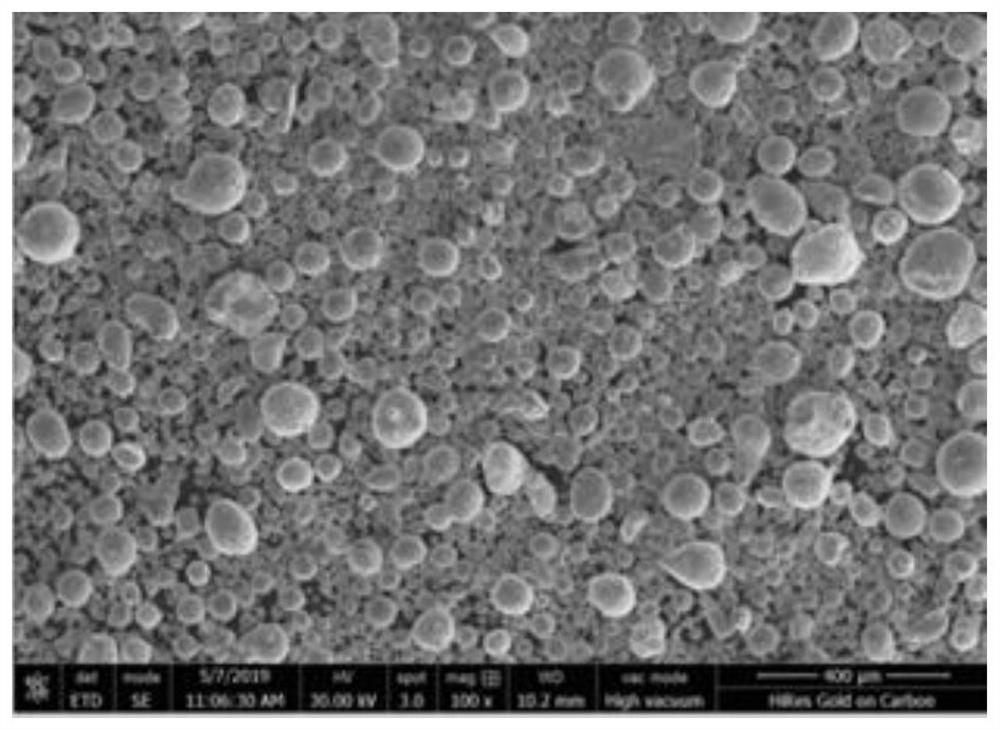

[0053] The preparation method of the flaky copper-based intermediate layer material comprises the following steps: mixing Ti, Sn, Ni, Ag, B, Al, La, Cu in proportion, first adopting vacuum melting, adopting vacuum melting and gas atomization, ultrasonic Sieve and make the middle layer material into 400 mesh spherical powder. Its microscopic appearance is as figure 1 shown.

[0054] The prepared copper-based intermediate layer powder material is used to directly braze alumina ceramics and 1A95 oxygen-free copper. The welding process parameters are as follows: the welding temperature parameter is set to 900 ° C, the pressure parameter is set to 0.1 MPa, and the holding time parameter is 10min.

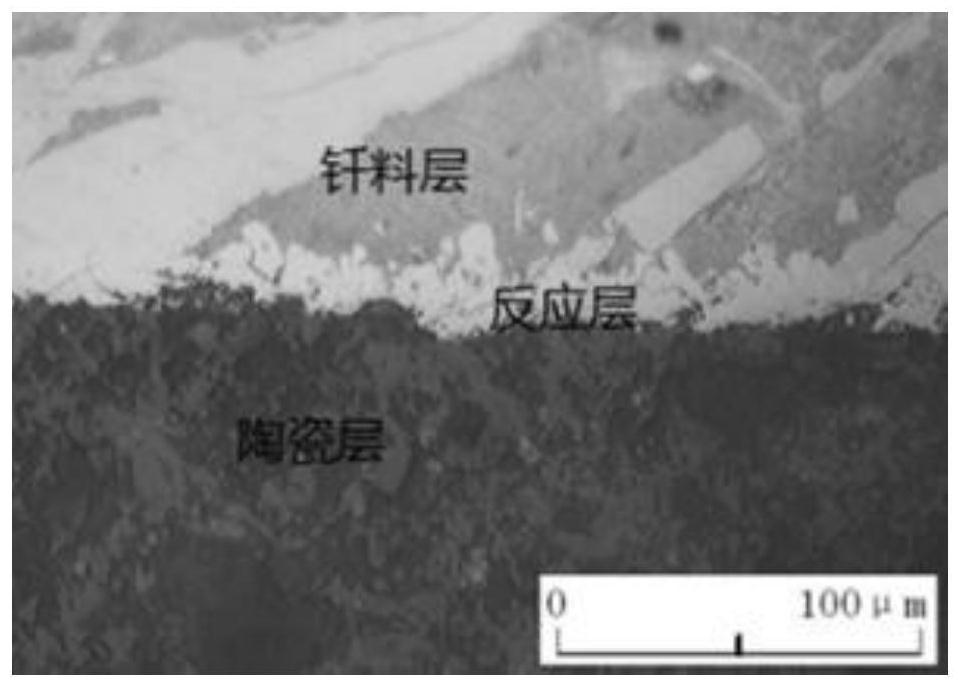

[0055] The microstructure of the weldment obtained by welding is shown in image 3 s...

Embodiment 2

[0057] A copper-based intermediate layer material is composed of the following components by weight percentage: 22.5% Ti, 10.5% Sn, 4.0% Ni, 1.0% Ag, 0.3% B, 0.2% Al, 0.15% La and the balance of copper.

[0058] The preparation method of the flaky copper-based intermediate layer material comprises the following steps: mixing Ti, Sn, Ni, Ag, B, Al, La, Cu in proportion, first adopting vacuum melting to melt it into an alloy ingot. The preparation method of the sheet-shaped copper-based intermediate layer material comprises the following steps: cutting the smelted alloy ingot into alloy strips by wire cutting and mechanical cutting processes, and subjecting the cut alloy strips to sandblasting surface treatment , remove the surface oil, and then the alloy strip after sand blasting is cleaned by alcohol and acetone ultrasonically to remove the surface oil, and the cleaned alloy strip is quickly quenched to make the middle layer material into a strip with a thickness of 60 μm and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com