Differential type metal particle drying device

A metal particle and drying device technology, which is applied in the direction of drying gas arrangement, granular material drying, non-progressive dryer, etc., can solve the problems of difficult uniform contact of metal powder, easy agglomeration of metal powder, and affecting drying efficiency, etc., to achieve Improve drying uniformity, facilitate aggregation, and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

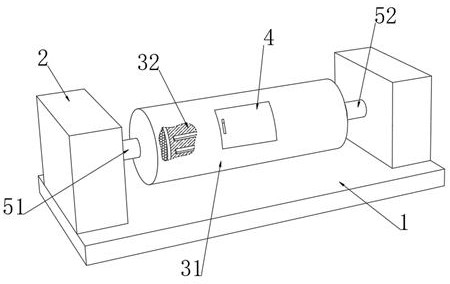

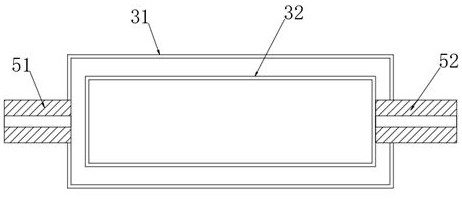

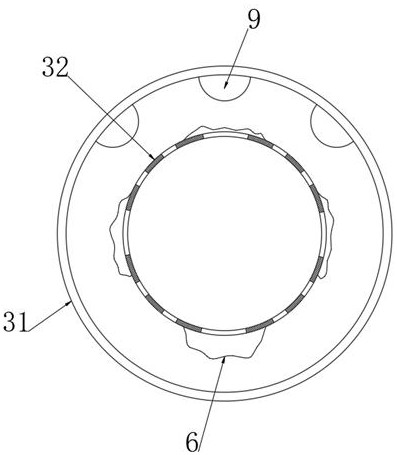

[0045] see Figure 1-2 , a differential speed metal particle drying device, comprising a bottom plate 1 and two positioning boxes 2 fixedly connected to the left and right upper ends of the bottom plate 1 respectively, a differential speed drying cylinder is connected between the two positioning boxes 2, and the differential speed drying cylinder includes a The outer powder transfer cylinder 31 and the inner powder transfer cylinder 32 located on the inner side, the outer end of the powder transfer cylinder 31 is fixed with a sealing door 4, a positioning box 2 and the powder transfer cylinder 31 are connected with an outer rotating shaft 51 through an electric rotating shaft, and An inner shaft 52 is connected between a positioning box 2 and the inner powder barrel 32 through an electric shaft. The powder transfer barrel 31 moves through the inner shaft 52. The outer shaft 51 and the inner shaft 52 are both tubular structures. The outer shaft 51 corresponds to the positioning ...

Embodiment 2

[0054] see Figure 10-11 The outer end of the throwing powder touch bar 9 is fixedly connected with a magnetron bisexual sheet, and the magnetron bisexual sheet includes an air sheet layer 101 fixedly connected with the outer end of the fixed magnetic sheet 91 and a plurality of throwing pads fixedly connected to the air sheet layer 101. Powder magnetic strip 102, a plurality of powder throwing magnetic strips 102 are not in contact with each other, and compressed inert gas is filled between the powder throwing strip 9 and the magnetron bisexual sheet, and the air sheet layer 101 is coated with LINE-X paint on the surface The elastic sealing structure of the coating is made, so that the wear resistance and tensile resistance of the air sheet layer 101 are enhanced, so that it is not easy to be damaged when it is continuously hit by the pocket cloth 6 .

[0055] The powder throwing touch strip 9 is an electromagnet, and the powder throwing touch strip 9 is electrically connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com