Standard sample for analyzing trace elements of high-purity tungsten and preparation method of standard sample

A standard sample and trace element technology, which is applied in the preparation of test samples, material analysis, material analysis by electromagnetic means, etc., can solve the problems of fewer types of elements covered, increase the types of elements, reduce costs, etc., and achieve composition Good uniformity, high accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 23kg of ammonium tungstate (purity 4N), high-quality pure manganese nitrate, barium nitrate, cobalt nitrate, cadmium nitrate, chromium nitrate, nickel nitrate, magnesium nitrate, bismuth nitrate, lead nitrate, antimony trioxide, tetrachloride Weigh 3.0g of tin, titanium powder, zinc chloride and strontium chloride.

[0033] Put the above reagents into an evaporating stirrer, evaporate and crystallize while stirring at 103°C for 12 hours, and obtain crude ammonium tungstate crystals with uniform composition. The obtained crystals are subjected to hydrogenation reduction (reduction temperature is 940°C, hydrogen flow rate is 5m3 / h) to obtain pure tungsten powder. The obtained tungsten powder is mechanically stirred, and then mechanically stirred for 150 hours after being crushed by a ball mill, and finally a tungsten powder precursor with a concentrated particle size distribution and uniform chemical composition is obtained.

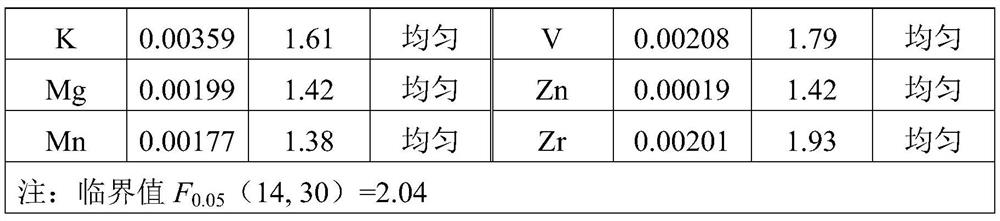

[0034] The homogenized high-purity tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com