Preparation method of molecularly imprinted electrochemical sensor for identifying glycine

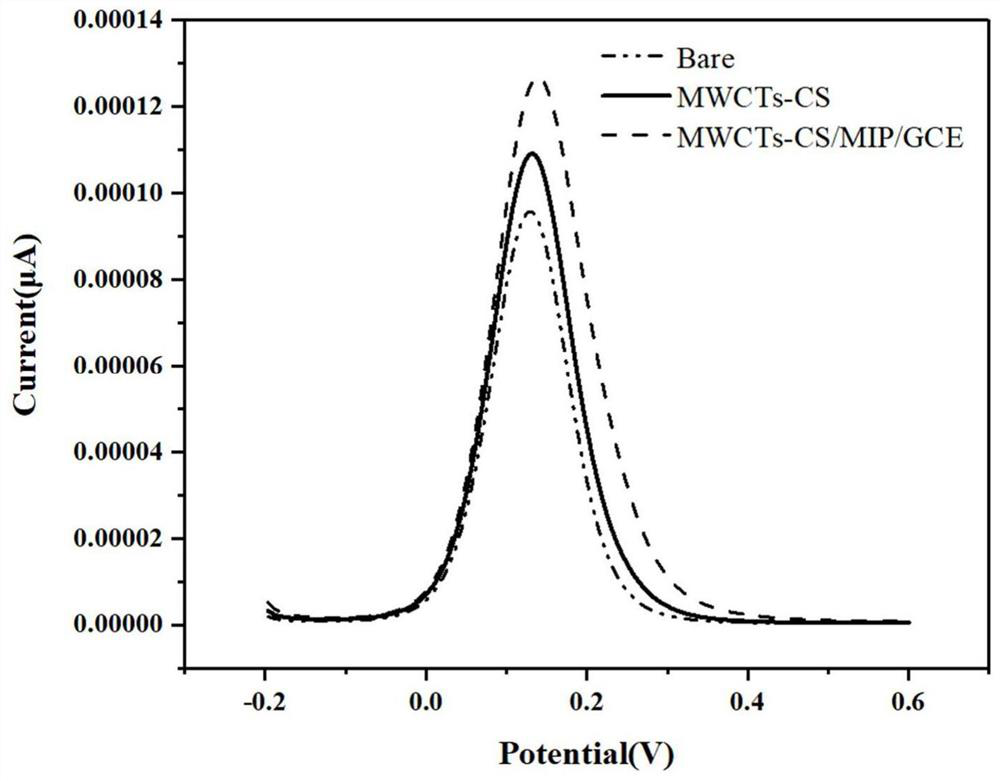

A technology of molecular imprinting and electrochemistry, applied in the direction of electrochemical variables of materials, nanotechnology for sensing, scientific instruments, etc., can solve problems affecting the absorption of other amino acids, breaking absorption balance, interfering with chromatographic analysis, etc., to achieve excellent electrochemistry Chemical properties, good reproducibility, and the effect of enhancing electrical signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Preparation of MWNTs-CS nanocomposite suspension: 10 mg of multi-walled carbon nanotube fine powder was weighed and dispersed in 10 mL of 1% acetic acid solution containing 1.0 mg chitosan. The ultrasonic treatment time was 120 min.

[0028] Step 2: Preparation of MWNTs-CS / GCE composite modified electrode: Polish the glassy carbon electrode with 20 nm alumina suspension slurry until the surface is smooth, ultrasonically rinse with absolute ethanol and deionized water for 30 s, and then wash with 0.5 M Soak in sulfuric acid solution, followed by ultrasonic cleaning with deionized water for 30 s. Cyclic voltammetry was used on the electrochemical workstation to scan from -0.4 V to 1.6 V at a scanning speed of 0.2 V / s. After 40 cycles of cyclic activation, 5 μL of MWNTs-CS nanocomposite suspension was dropped into The surface of the pretreated glassy carbon electrode was dried overnight at 37 °C to obtain a MWNTs-CS / GCE composite modified electrode.

[0029] Step...

Embodiment 2

[0032] Step 1: Preparation of MWNTs-CS nanocomposite suspension: 10 mg of multi-walled carbon nanotube fine powder was weighed and dispersed in 10 mL of 1% acetic acid solution containing 1.0 mg chitosan. The ultrasonic treatment time was 120 min.

[0033] Step 2: Preparation of MWNTs-CS / GCE composite modified electrode: Polish the glassy carbon electrode with 20 nm alumina suspension slurry until the surface is smooth, ultrasonically rinse with absolute ethanol and deionized water for 30 s, and then wash with 0.5 M Soak in sulfuric acid solution, followed by ultrasonic cleaning with deionized water for 30 s. Cyclic voltammetry was used on the electrochemical workstation to scan from -0.4 V to 1.6 V at a scanning speed of 0.2 V / s. After 40 cycles of activation, the glassy carbon electrode was thoroughly cleaned, and then 5 μL of The MWNTs-CS nanocomposite suspension was dropped onto the surface of the pretreated glassy carbon electrode and dried overnight at 37 °C to obtain t...

Embodiment 3

[0037] Step 1: Preparation of MWNTs-CS nanocomposite suspension: 10 mg of multi-walled carbon nanotube fine powder was weighed and dispersed in 10 mL of 1% acetic acid solution containing 1.0 mg chitosan. Sonication time is 120 min

[0038]Step 2: Preparation of MWNTs-CS / GCE composite modified electrode: Polish the glassy carbon electrode with 20 nm alumina suspension slurry until the surface is smooth, ultrasonically rinse with absolute ethanol and deionized water for 30 s, and then wash with 0.5 M Soak in sulfuric acid solution, followed by ultrasonic cleaning with deionized water for 30 s. Cyclic voltammetry was used on the electrochemical workstation to scan from -0.4 V to 1.6 V at a scanning speed of 0.2 V / s. After 40 cycles of cyclic activation, 5 μL of MWNTs-CS nanocomposite suspension droplets MWNTs-CS / GCE composite modified electrode was obtained by inserting it into the surface of the pretreated glassy carbon electrode and drying it overnight at 37 °C.

[0039] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com