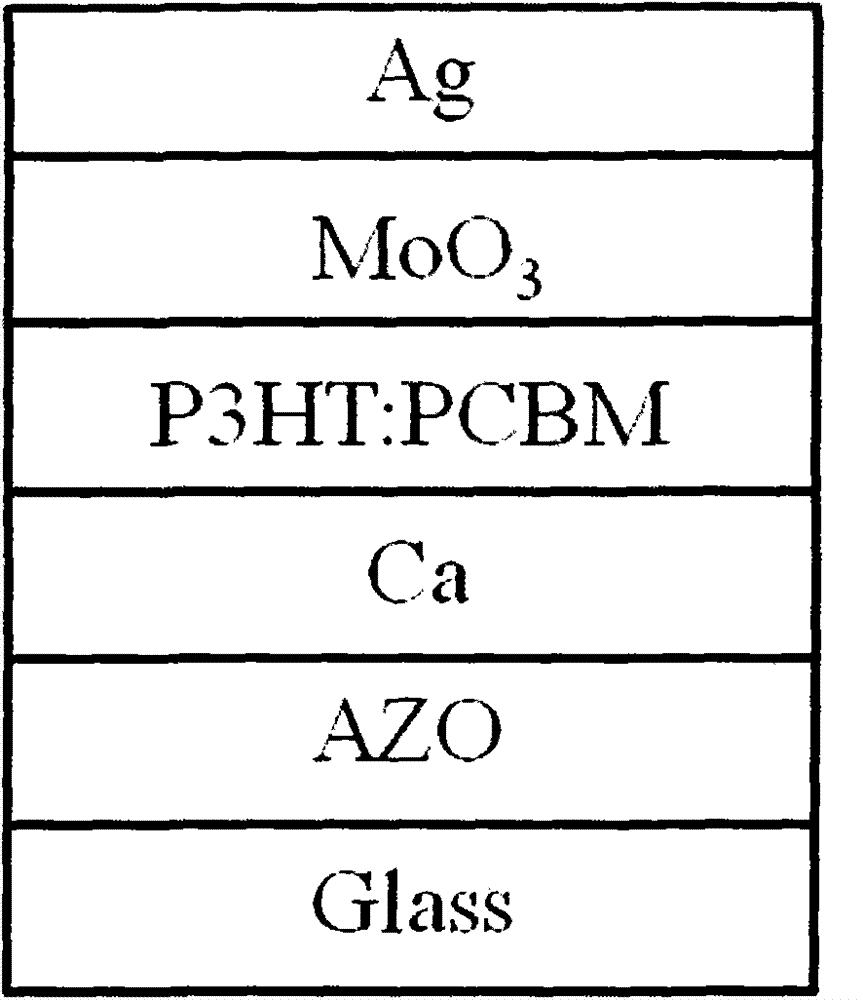

Organic solar cell based on AZO/Ca cathode and manufacturing method thereof

A solar cell and organic technology, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of lack of device structure and preparation technology, rare research and reports, etc., to improve short-circuit current density and fill factor, easy Large-area film formation and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The realization steps of the present invention are as follows:

[0038] Step 1, cleaning the substrate substrate.

[0039] The AZO glass substrate was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 15 minutes in sequence. After cleaning, it was blown dry with a nitrogen gun, and then placed in a nitrogen atmosphere glove box. The thickness of glass is about 2mm, the thickness of AZO is about 980nm, and the sheet resistance is about 10Ω / □.

[0040] Step 2, depositing a Ca electron transport layer.

[0041] Thermally evaporate the Ca-modified layer with a background vacuum of 4×10 -4 Pa, current 27A, evaporation rate 0.05nm / s, thickness 5nm;

[0042] Step 3, depositing the photoactive layer of P3HT:PCBM.

[0043]First, P3HT and PCBM were dissolved in 1-2 chlorobenzene respectively to obtain a solution with a concentration of 20 mg / mL. After stirring at room temperature for 4 hours, they were mixed at a volume ratio of 1:0....

Embodiment 2

[0054] The realization steps of the present invention are as follows:

[0055] Step 1, cleaning the substrate substrate.

[0056] The AZO glass substrate was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 15 minutes in sequence. After cleaning, it was blown dry with a nitrogen gun, and then placed in a nitrogen atmosphere glove box. The thickness of glass is about 2mm, the thickness of AZO is about 980nm, and the sheet resistance is about 10Ω / □.

[0057] Step 2, depositing a Ca electron transport layer.

[0058] Thermally evaporate the Ca-modified layer with a background vacuum of 4×10 -4 Pa, current 27A, evaporation rate 0.05nm / s, thickness 1nm;

[0059] Step 3, depositing the photoactive layer of P3HT:PCBM.

[0060] First, P3HT and PCBM were dissolved in 1-2 chlorobenzene respectively to obtain a solution with a concentration of 20 mg / mL. After stirring at room temperature for 4 hours, they were mixed at a volume ratio of 1:0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com