Fresh water salt-resistant tough cement paste for gas storage

A technology for gas storage and cement slurry, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of long thickening time, weak salt resistance, long cement slurry consolidation time, etc. Early strength, effect of improving salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

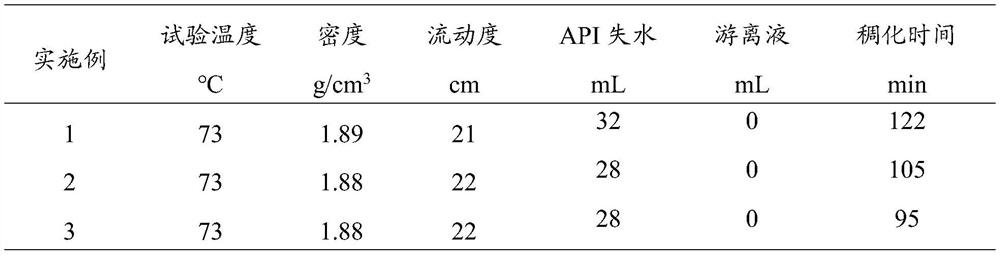

Embodiment 1

[0043] This example is the cement slurry system for sealing the salt layer section of the Wen 23 gas storage, including the following raw materials in parts by weight: 100 parts of G-grade cement, 42 parts of fresh water, 0.3 parts of dispersant USZ, 3.0 parts of elastic agent M91S, and expansion agent 0.3 part of G502S, 4 parts of fluid loss reducer ZYJ-1L, 0.1 part of fiber WX, 0.5 part of anti-salt coagulant M71S, 0.2 part of defoamer G603L.

[0044] The preparation method is as follows: mixing the above-mentioned raw materials according to parts by weight.

Embodiment 2

[0046]This example is the cement slurry system for sealing the salt layer section of Wen 23 gas storage, including the following raw materials in parts by weight: 100 parts of G-grade cement, 42 parts of fresh water, 0.5 parts of dispersant USZ, 3.0 parts of elastic agent M91S, and expansion agent 0.5 part of G502S, 5 parts of fluid loss reducer ZYJ-1L, 0.1 part of fiber WX, 1.0 part of anti-salt coagulant M71S, 0.3 part of defoamer G603L.

[0047] The preparation method is as follows: mixing the above-mentioned raw materials according to parts by weight.

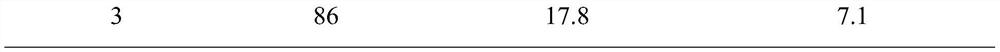

Embodiment 3

[0049] This example is the cement slurry system for sealing the salt layer section of the Wen 23 gas storage, including the following raw materials in parts by weight: 100 parts of G-grade cement, 42 parts of fresh water, 0.5 parts of dispersant USZ, 3.5 parts of elastic agent M91S, and expansion agent 0.5 parts of G502S, 5 parts of fluid loss reducer ZYJ-1L, 0.1 parts of fiber WX, 1.5 parts of anti-salt coagulant M71S, 0.3 parts of defoamer G603L.

[0050] The preparation method is as follows: mixing the above-mentioned raw materials according to parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com