A method for preparing egg yolk lecithin using two-step subcritical extraction technology

A technology of egg yolk lecithin and extraction technology, applied in the field of preparing egg yolk lecithin, can solve the problems of organic solvent residue, loss of beneficial components, complicated pretreatment, etc., and achieves the effects of lubricating skin and mucous membranes, no solvent residue, and low extraction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

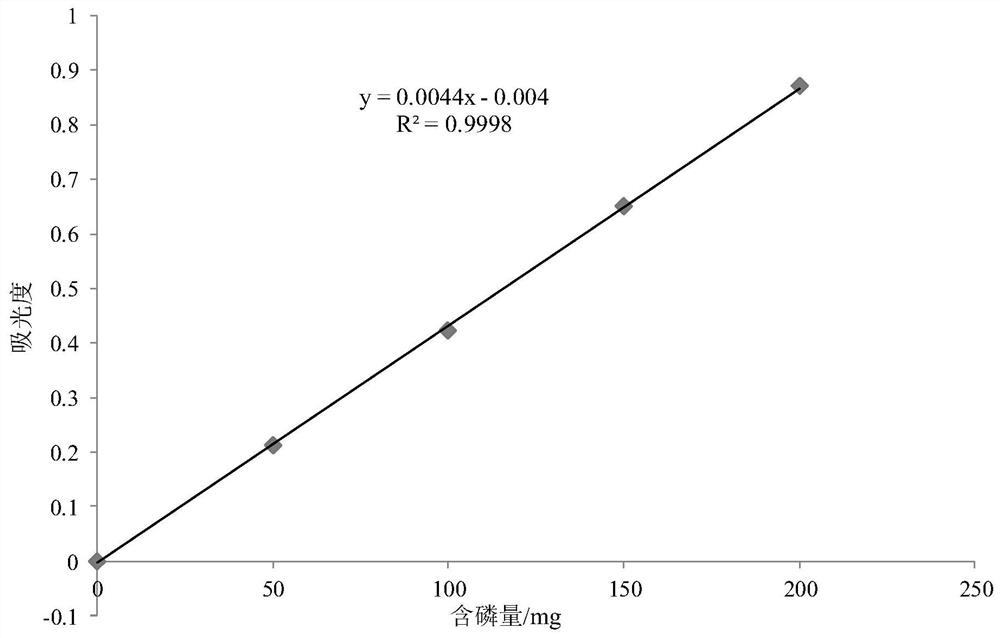

Image

Examples

Embodiment 1

[0042] A kind of method adopting subcritical extraction technology to prepare egg yolk lecithin, comprises the steps:

[0043] (1) Raw material preparation:

[0044]Select fresh eggs, beat the eggs to separate egg whites and egg yolks, collect egg yolks, freeze at -18°C for 8 hours, and then refrigerate at 4°C overnight to obtain egg yolk gels; mix egg yolk gels with deionized water at a ratio of 1:5 Mass ratio mixing, homogenization with a high-speed shearing machine (11000rpm) for 2 minutes to form egg yolk suspension, centrifugation at 8000g to collect the precipitate, replenishing deionized water of equal weight, and finally spray drying (inlet air temperature is 170 ° C, air outlet temperature is 85°C) to obtain egg yolk powder; the supernatant is used to prepare by-product egg yolk immunoglobulin;

[0045] (2) Granulation:

[0046] Making the egg yolk powder obtained in step (1) into cylindrical granules with a diameter of 7 mm to obtain granular egg yolk powder; where...

Embodiment 2

[0055] adjust 1

[0056] Adjust the feed liquid in step (4) of Example 1 as shown in Table 1, the extraction pressure is 2.5 MPa, the extraction temperature is 45° C., and the extraction time is 150 min. Others are consistent with Example 1 to obtain lecithin.

[0057] The obtained lecithin is tested, and the test results are shown in Table 1:

[0058] Table 1

[0059] Ratio of solid to liquid (w / v) Lecithin yield (%) Lecithin purity (%) 1:15 (Example 1) 92.7 95.8 1:5 85.4 88.3 1:3 74.5 78.9 1:17 92.8 93.4 1:20 93.0 94.5

[0060] It can be seen from Table 1 that when extracting butane, keep the extraction pressure at 2.5 MPa, the extraction temperature at 45°C, and the extraction time at 150 min. Within a certain range, the yield and purity of egg yolk lecithin increase with the increase in the volume of butane , when the ratio of solid to liquid is 1:15, 1:17 and 1:20, there is no significant difference in the yield and purit...

Embodiment 3

[0116] A kind of method adopting subcritical extraction technology to prepare egg yolk lecithin, comprises the steps:

[0117] (1) Raw material preparation:

[0118] Select fresh eggs, beat the eggs to separate egg whites and egg yolks, collect egg yolks, freeze at -30°C for 8 hours, and then refrigerate at 4°C overnight to obtain egg yolk gels; mix egg yolk gels with deionized water at a ratio of 1:5 Mass ratio mixing, homogenization with a high-speed shearing machine (11000rpm) for 2 minutes to form egg yolk suspension, centrifugation at 7000g to collect the precipitate, replenishing deionized water of equal weight, and finally spray drying (inlet air temperature is 180 ° C, air outlet temperature is 85°C) to obtain egg yolk powder; the supernatant is used to prepare by-product egg yolk immunoglobulin;

[0119] (2) Granulation:

[0120] Making the egg yolk powder obtained in step (1) into cylindrical granules with a diameter of 5 mm to obtain granular egg yolk powder; wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com